ก.พ. . 13, 2025 09:35

Back to list

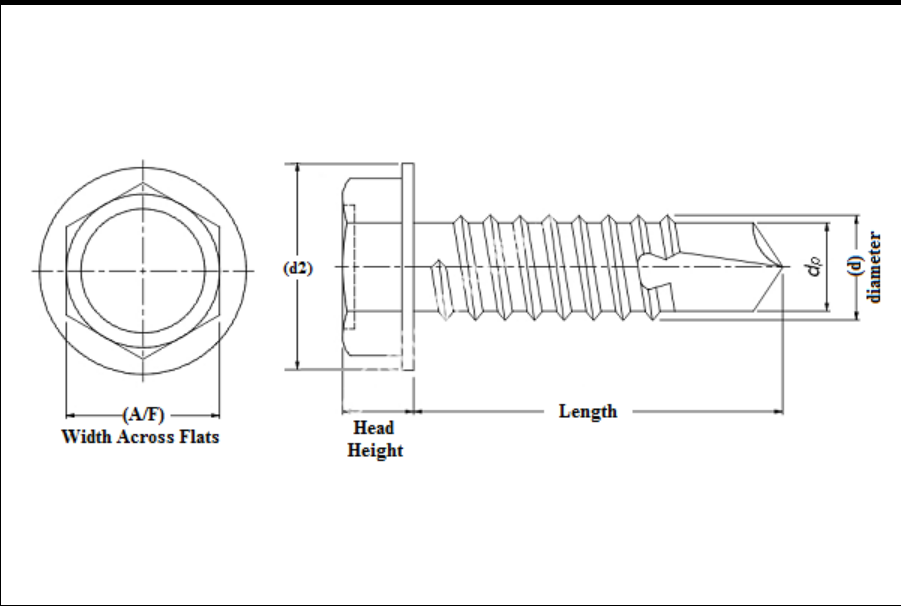

self tapping screw length

Self-tapping screws, a critical component in various construction and DIY projects, play an indispensable role in the world of fasteners. Understanding the ideal length of these screws is crucial for ensuring both the integrity and success of your project. The length of a self-tapping screw not only affects the durability of the assembly but also influences the efficiency of the installation process. This article delves deep into the nuances of selecting the optimal self-tapping screw length, drawing insights from industry experts and seasoned professionals.

In order to maintain a high level of trustworthiness and reliability in project assembly, purchasing screws from reputable suppliers with certifications is advisable. These companies not only provide quality assurance but also often offer expert assistance in choosing the suitable screw length for your application. As such, building a relationship with trustworthy suppliers is considered a best practice within the industry. Experience has shown that improper selection of self-tapping screw length has implications beyond mere mechanical failure; it can affect the longevity and safety of the entire structure. Experts recommend meticulous planning and consultation during the initial stages of any construction or DIY project. By adhering to these practices, one can achieve the intended outcome while maintaining structural integrity. Overall, selecting the correct self-tapping screw length is a decision that balances practical requirements, material considerations, and professional guidance. By approaching this task with the right expertise and resources, you can ensure that your construction endeavors are not only effective but also exemplary in quality and reliability. This comprehensive understanding elevates your work, reinforcing your authority and trustworthiness in fastener-related ventures.

In order to maintain a high level of trustworthiness and reliability in project assembly, purchasing screws from reputable suppliers with certifications is advisable. These companies not only provide quality assurance but also often offer expert assistance in choosing the suitable screw length for your application. As such, building a relationship with trustworthy suppliers is considered a best practice within the industry. Experience has shown that improper selection of self-tapping screw length has implications beyond mere mechanical failure; it can affect the longevity and safety of the entire structure. Experts recommend meticulous planning and consultation during the initial stages of any construction or DIY project. By adhering to these practices, one can achieve the intended outcome while maintaining structural integrity. Overall, selecting the correct self-tapping screw length is a decision that balances practical requirements, material considerations, and professional guidance. By approaching this task with the right expertise and resources, you can ensure that your construction endeavors are not only effective but also exemplary in quality and reliability. This comprehensive understanding elevates your work, reinforcing your authority and trustworthiness in fastener-related ventures.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News