ม.ค. . 25, 2025 04:00

Back to list

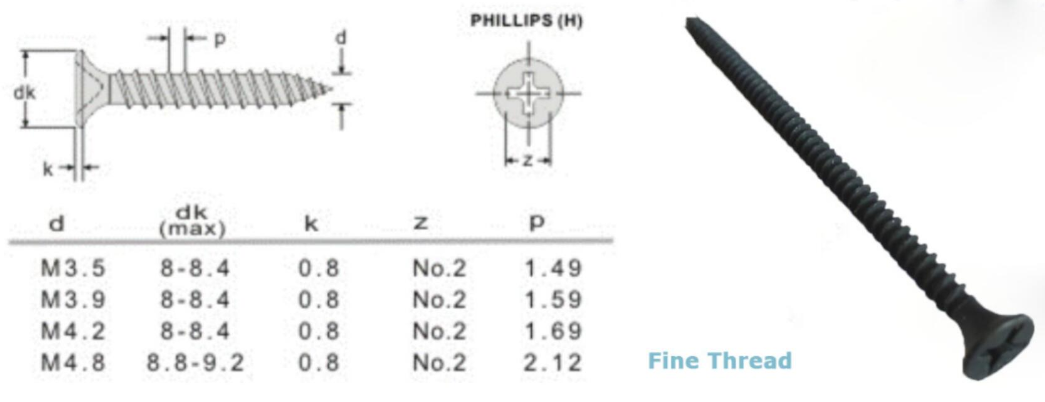

csk head self tapping screw

When it comes to achieving precision in construction and DIY projects, the significance of selecting the right size for self-tapping screw holes cannot be overstated. This guide serves as an indispensable tool for professionals and enthusiasts alike who seek efficiency, reliability, and expertise in their endeavors. Here's an in-depth exploration of self-tapping screw holes and the importance of choosing the correct size, with a comprehensive chart to aid in your decision-making.

- Metric Equivalence - Including metric sizes ensures global applicability, as many current projects may have components sourced internationally. Authoritative Guidance in Practice Professional builders and engineers stress the importance of proper hole sizing related to the longevity and reliability of the finished project. An incorrect fit can lead to mechanical failures, financial loss, or increased safety risks. Therefore, adhering to this guide ensures both safety and durability. Innovative Tools and Technologies The introduction of digitally adaptable tools, such as smartphone apps or CNC interfaces, allows precise measurement and hole creation, which adheres to the recommended chart specifications. These innovations increase the accuracy of DIY projects and professional works alike, bridging the gap between digital and manual efforts. Building Trust Trust is built through consistent and reliable results. Users are encouraged to practice on scrap material before final application, validating the chart's information in real-world trials. Post-application feedback can be recorded to refine personal or company-specific future guidance. Rapid Adaptation Staying informed with the latest developments regarding materials and types of self-tapping screws ensures that the chart remains essential and up-to-date with industry standards. Always incorporate new data and revisions from trusted manufacturing and engineering sources. By embracing these elements of expert knowledge, practical experience, and trust, users can optimize their projects with confidence. Navigating the nuances of self-tapping screw hole sizes is no longer overwhelming with a robust set of guidelines, underpinned by this comprehensive chart. Leveraging these insights transforms challenges into opportunities for excellence and innovation in any construction undertaking.

- Metric Equivalence - Including metric sizes ensures global applicability, as many current projects may have components sourced internationally. Authoritative Guidance in Practice Professional builders and engineers stress the importance of proper hole sizing related to the longevity and reliability of the finished project. An incorrect fit can lead to mechanical failures, financial loss, or increased safety risks. Therefore, adhering to this guide ensures both safety and durability. Innovative Tools and Technologies The introduction of digitally adaptable tools, such as smartphone apps or CNC interfaces, allows precise measurement and hole creation, which adheres to the recommended chart specifications. These innovations increase the accuracy of DIY projects and professional works alike, bridging the gap between digital and manual efforts. Building Trust Trust is built through consistent and reliable results. Users are encouraged to practice on scrap material before final application, validating the chart's information in real-world trials. Post-application feedback can be recorded to refine personal or company-specific future guidance. Rapid Adaptation Staying informed with the latest developments regarding materials and types of self-tapping screws ensures that the chart remains essential and up-to-date with industry standards. Always incorporate new data and revisions from trusted manufacturing and engineering sources. By embracing these elements of expert knowledge, practical experience, and trust, users can optimize their projects with confidence. Navigating the nuances of self-tapping screw hole sizes is no longer overwhelming with a robust set of guidelines, underpinned by this comprehensive chart. Leveraging these insights transforms challenges into opportunities for excellence and innovation in any construction undertaking.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News