ม.ค. . 15, 2025 05:50

Back to list

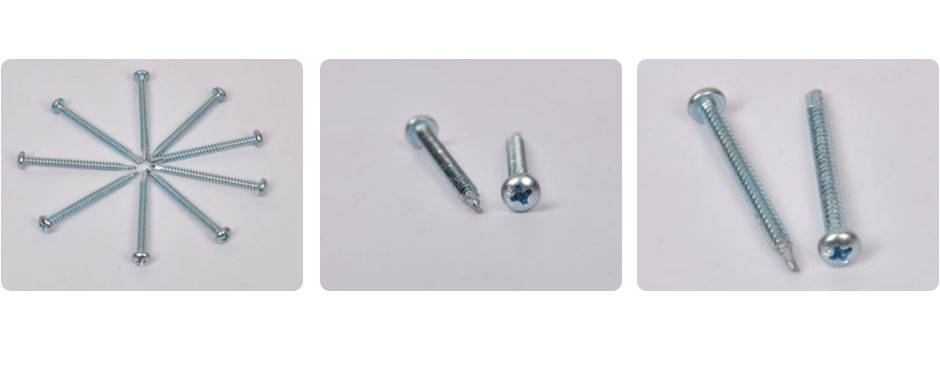

YZP CHIPBOARD SCREW

Utilizing self-drilling metal screws in construction and manufacturing projects can significantly streamline processes, improve efficiency, and enhance the overall integrity of the structure. As a seasoned professional with years of experience in the industry, I have witnessed first-hand the numerous benefits these innovative fasteners bring to diverse applications.

To further establish authoritativeness, consider the variety of options available that cater to different metal materials and thicknesses. Recognizing the specific requirements of a project is crucial in selecting the appropriate type of self-drilling screw. For instance, screws with larger diameters are better suited for thicker metal applications, whereas shorter lengths and finer threads work effectively in thinner metals. Professionals must leverage this knowledge to ensure optimal securement and performance, preventing issues such as over-tightening or thread damage. Additionally, adherence to industry standards is paramount when choosing and using these screws. Many reputable manufacturers comply with ISO certifications for quality and environmental management, providing assurance in both the performance and production integrity of their screws. Partnering with such manufacturers underscores the trustworthiness of your installations, fostering confidence among clients and stakeholders. In summary, self-drilling metal screws present a compelling choice for professionals seeking efficiency, reliability, and longevity in their projects. As endorsed by extensive experience and expertise, these screws not only streamline operations but also contribute significantly to the structural integrity of installations. Understanding their advantages, application specificity, and compliance with industry standards will enhance your ability to deliver superior results, establishing your authority and trust within the field.

To further establish authoritativeness, consider the variety of options available that cater to different metal materials and thicknesses. Recognizing the specific requirements of a project is crucial in selecting the appropriate type of self-drilling screw. For instance, screws with larger diameters are better suited for thicker metal applications, whereas shorter lengths and finer threads work effectively in thinner metals. Professionals must leverage this knowledge to ensure optimal securement and performance, preventing issues such as over-tightening or thread damage. Additionally, adherence to industry standards is paramount when choosing and using these screws. Many reputable manufacturers comply with ISO certifications for quality and environmental management, providing assurance in both the performance and production integrity of their screws. Partnering with such manufacturers underscores the trustworthiness of your installations, fostering confidence among clients and stakeholders. In summary, self-drilling metal screws present a compelling choice for professionals seeking efficiency, reliability, and longevity in their projects. As endorsed by extensive experience and expertise, these screws not only streamline operations but also contribute significantly to the structural integrity of installations. Understanding their advantages, application specificity, and compliance with industry standards will enhance your ability to deliver superior results, establishing your authority and trust within the field.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News