ก.พ. . 11, 2025 20:02

Back to list

pan head self tapping screw sizes

Understanding the dimensions and varieties of pan head self-tapping screws is crucial for any DIY enthusiast or professional builder who seeks reliability and efficiency in construction and manufacturing projects. As an integral component in fastening technologies, these screws eliminate the need for pre-drilling, thanks to their innovative design which allows them to tap their own mating threads in various materials.

Additionally, different thread types play a significant role in the functionality of pan head self-tapping screws. Coarse threads are generally used for softer materials, such as softwoods and plastics, as they offer better grip and reduce the chance of material splitting. Fine threads are optimal for harder substances such as metals, providing a tighter fit and more durable hold. In choosing the appropriate pan head self-tapping screw, it is equally important to consider the material of the screw itself. Stainless steel screws are renowned for their corrosion resistance and are preferred for projects exposed to moisture. On the other hand, carbon steel screws with protective finishes can offer superior strength and are often used in high-load applications. Ensuring the reliability and longevity of your construction or repair work requires selecting the right pan head self-tapping screw based on these dimensions and criteria. Misjudging the size can lead to structural failings, such as poor holding power or material damage, thus undermining the integrity of your work. Furthermore, establishing a reliable source for purchasing screws assures quality consistency, adherence to dimensional standards, and availability of necessary sizes. Trusted manufacturers will offer detailed specifications and usage guides, lending expertise to support optimal selection. In conclusion, the size selection of pan head self-tapping screws should never be underestimated as a factor contributing to the success of any project. By leveraging a nuanced understanding of screw dimensions, thread types, and material composites, you ensure that each choice bolsters the structure’s integrity while meeting project specifications. Always consult, when necessary, an expert or detailed resource when dealing with complex applications to reinforce your decision-making with authoritative information ensuring the utmost trustworthiness and efficacy of your handiwork.

Additionally, different thread types play a significant role in the functionality of pan head self-tapping screws. Coarse threads are generally used for softer materials, such as softwoods and plastics, as they offer better grip and reduce the chance of material splitting. Fine threads are optimal for harder substances such as metals, providing a tighter fit and more durable hold. In choosing the appropriate pan head self-tapping screw, it is equally important to consider the material of the screw itself. Stainless steel screws are renowned for their corrosion resistance and are preferred for projects exposed to moisture. On the other hand, carbon steel screws with protective finishes can offer superior strength and are often used in high-load applications. Ensuring the reliability and longevity of your construction or repair work requires selecting the right pan head self-tapping screw based on these dimensions and criteria. Misjudging the size can lead to structural failings, such as poor holding power or material damage, thus undermining the integrity of your work. Furthermore, establishing a reliable source for purchasing screws assures quality consistency, adherence to dimensional standards, and availability of necessary sizes. Trusted manufacturers will offer detailed specifications and usage guides, lending expertise to support optimal selection. In conclusion, the size selection of pan head self-tapping screws should never be underestimated as a factor contributing to the success of any project. By leveraging a nuanced understanding of screw dimensions, thread types, and material composites, you ensure that each choice bolsters the structure’s integrity while meeting project specifications. Always consult, when necessary, an expert or detailed resource when dealing with complex applications to reinforce your decision-making with authoritative information ensuring the utmost trustworthiness and efficacy of your handiwork.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

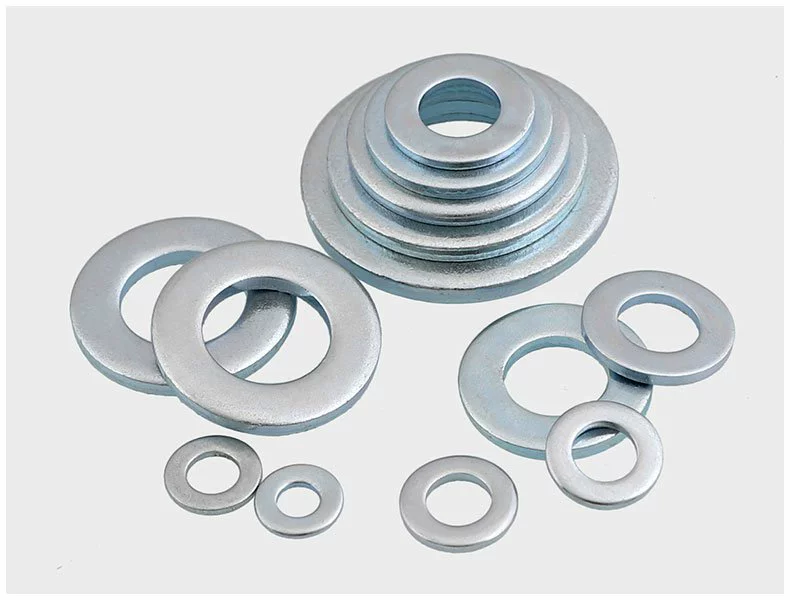

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News