pan head self drilling screw manufacturers pricelist

Understanding the Price List of Pan Head Self-Drilling Screws A Guide for Manufacturers and Buyers

In the world of construction and manufacturing, the importance of high-quality fasteners cannot be overstated. Among these, pan head self-drilling screws stand out due to their unique design and versatile applications. These screws are essential for ensuring secure and reliable connections in various structural and mechanical projects. With the rise in demand for these fasteners, it becomes crucial for buyers and manufacturers alike to understand the pricing and factors that influence the cost of pan head self-drilling screws.

What are Pan Head Self-Drilling Screws?

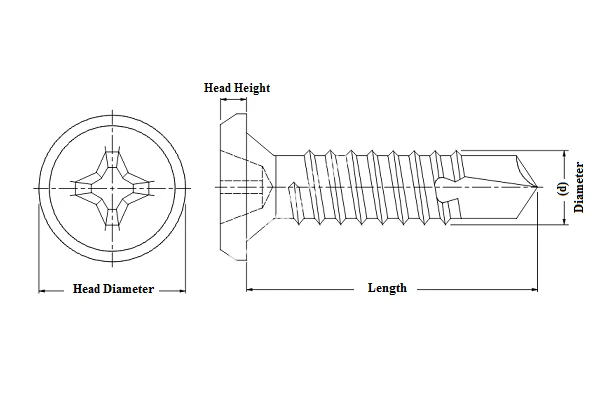

Pan head self-drilling screws, also known as self-tapping screws, are designed with a pan-shaped head that provides a broad surface area for better grip and torque. They feature a sharp tip that allows them to drill into materials without the need for a pre-drilled hole. This functionality makes them especially popular in metal-to-metal applications, as well as in installations involving wood and plastic.

Due to their user-friendly design and efficiency, pan head self-drilling screws are commonly used in various industries, including construction, automotive, and manufacturing. Their ability to reduce installation time while ensuring structural integrity makes them a preferred choice for professionals.

Factors Influencing the Price List

When exploring the price list for pan head self-drilling screws, several factors come into play

1. Material Composition The most common materials used for these screws are stainless steel, carbon steel, and galvanized steel. Stainless steel screws tend to be more expensive due to their corrosion resistance and durability, while carbon steel screws are generally more affordable but may not withstand harsh environmental conditions.

2. Coating and Finish The finish of the screws can significantly affect the price. Screws with additional coatings, such as zinc plating or black oxide, are designed to enhance corrosion resistance. These coatings increase manufacturing costs, which can reflect in the final price.

3. Diameter and Length The size of the screw—its diameter and length—also governs its price. Larger screws or those with special threading configurations typically involve more material and advanced manufacturing processes, raising the cost.

pan head self drilling screw manufacturers pricelist

4. Volume of Purchase Many manufacturers offer tiered pricing, where larger orders result in lower per-unit costs. For contractors and construction companies, bulk purchasing can be an effective way to manage costs while ensuring they have ample supply for their projects.

5. Brand and Manufacturer Reputation The reputation of the manufacturer can impact pricing. Established brands may charge a premium for their products due to perceived reliability and quality assurance. Conversely, lesser-known manufacturers might offer competitive prices to capture market share.

6. Market Trends and Demand Like many products, the prices of pan head self-drilling screws can fluctuate based on market demand. Economic conditions, supply chain challenges, and changes in raw material costs can all lead to price adjustments.

Navigating the Price List

For buyers, understanding the detailed price list of pan head self-drilling screws is crucial for making informed decisions. Here are a few tips

- Compare Prices Across Suppliers Obtain quotes from multiple manufacturers to compare prices adequately. This practice helps ensure you are getting the best deal without compromising on quality.

- Evaluate Quality versus Cost While it might be tempting to go for the cheapest option available, consider the long-term implications of using lower-quality screws. Investing in durable screws can lead to reduced maintenance costs and greater reliability.

- Establish a Relationship with Suppliers Building a solid relationship with a supplier can lead to better pricing, exclusive deals, and insights into upcoming price changes.

In conclusion, understanding the price list for pan head self-drilling screws involves considering various factors that influence their cost. Through careful evaluation and smart purchasing strategies, buyers can ensure they acquire high-quality screws that meet their project's needs while optimizing their budget. Whether you are a manufacturer or a construction professional, being informed about these aspects is key to successful procurement and project execution.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024