high quality screw placement for drywall

High-Quality Screw Placement for Drywall A Comprehensive Guide

Drywall installation is a common yet critical task in construction and renovation projects. Proper screw placement is essential for ensuring the structural integrity, longevity, and aesthetics of the wall. In this article, we will explore the key factors to consider for achieving high-quality screw placement for drywall.

Understanding Drywall Basics

Before diving into screw placement techniques, it is important to understand the nature of drywall itself. Typically made from a gypsum core sandwiched between two sheets of heavy paper, drywall panels are available in various thicknesses and sizes. The most common thicknesses are 1/2 inch and 5/8 inch, with the latter often used in ceilings and fire-rated applications.

Tools and Materials Needed

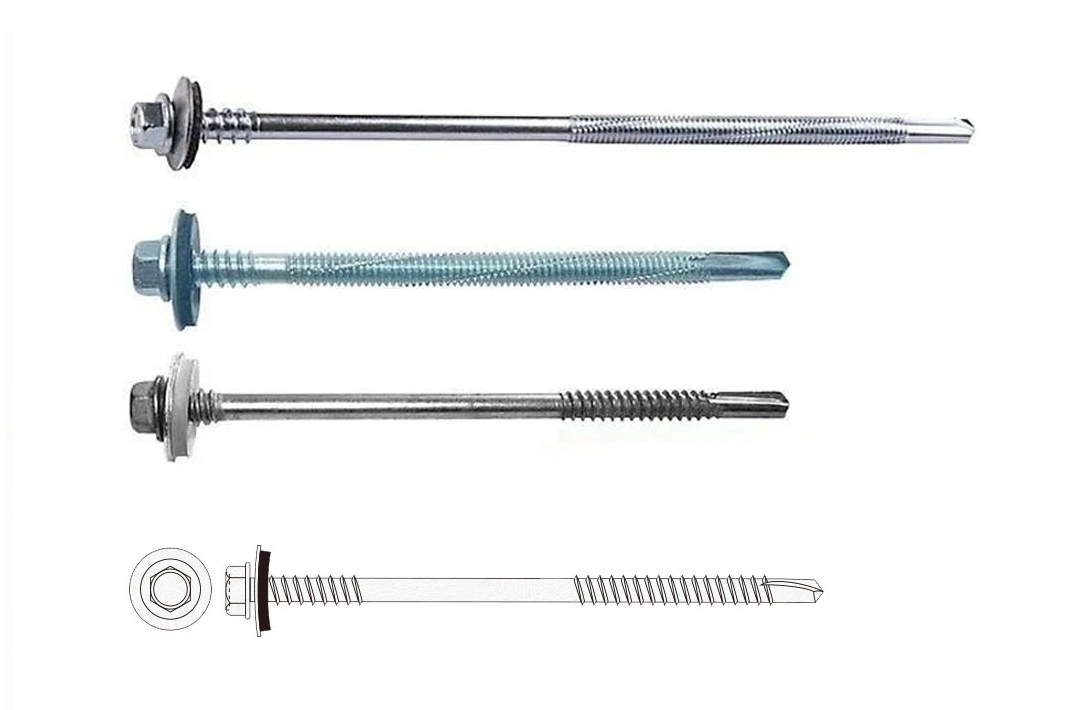

To achieve high-quality screw placement, you will need the following tools and materials

1. Screws Use drywall screws (often 6 or 8) specifically designed for fastening drywall to studs. 2. Drill/driver A cordless drill with a suitable bit for driving screws. 3. Screw gun (optional) A specialized tool that ensures proper screw depth and consistency. 4. Measuring tape For accurate measurements. 5. Level or square To ensure your drywall is straight and properly aligned. 6. Stud finder To locate the metal or wooden studs behind the drywall.

Screw Placement Guidelines

high quality screw placement for drywall

1. Stud Alignment Identify and mark the location of the studs behind the drywall using a stud finder. In most cases, studs are spaced 16 inches on center, but always verify this measurement. Ensure that the edges of your drywall panels align with these studs for optimal support.

2. Panel Installation When installing drywall panels, it is advisable to hang them horizontally. This method provides a stronger wall and minimizes the number of joints visible in the finished project.

3. Screw Spacing Place screws along the edges of the drywall and in the field (the central portion of the panel). A typical guideline is to place screws 16 inches apart along the edges and 12 inches apart in the field. This spacing ensures adequate support and minimizes the risk of cracking or sagging.

4. Depth of Insertion When driving screws, it is crucial to achieve the correct depth. The screws should be driven just below the surface of the drywall without breaking the paper face. A screw gun is particularly useful here, as it helps maintain consistent depth and reduces the risk of over-driving.

5. Avoiding Damage To prevent damage to the drywall, always drill straight and avoid angling the screws. Angled screws can lead to paper tear and a compromised surface, making it difficult to achieve a smooth finish when taping and mudding.

6. Final Inspection Once all screws are in place, inspect the wall for any protruding screws or uneven surfaces. All screws should be embedded just below the surface to ensure a smooth finish during the taping and mudding process.

Conclusion

High-quality screw placement is vital for the overall success of a drywall installation. Following these guidelines ensures a sturdy, well-finished wall that can withstand the test of time. Proper planning, the right tools, and attention to detail during the installation process will yield professional results in your drywall projects. With practice, anyone can master the art of drywall installation, leading to impressive and durable results in any space.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024