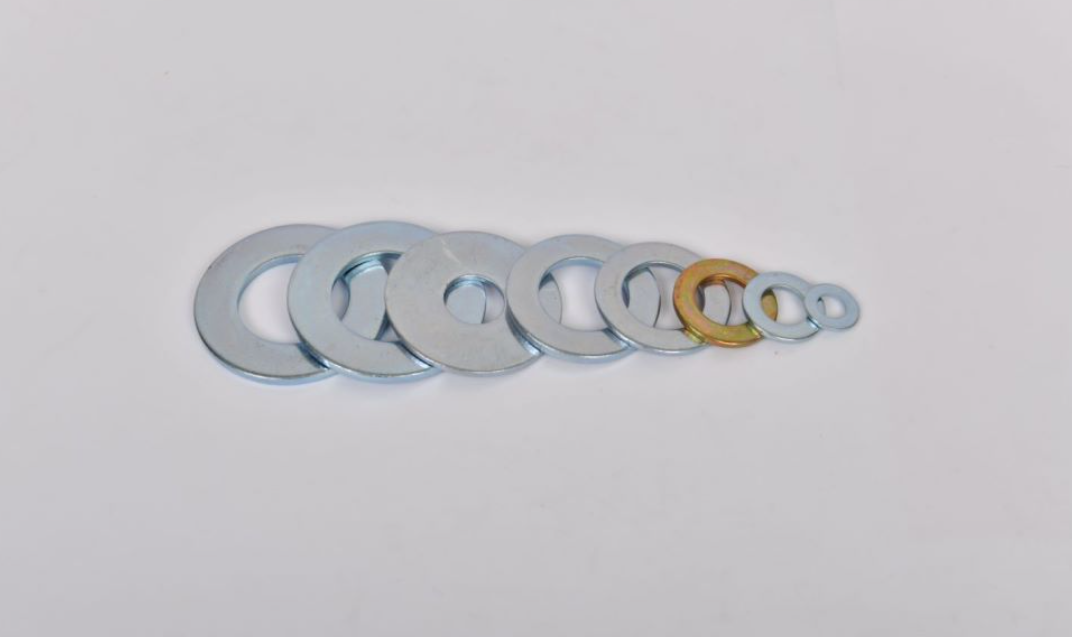

high quality din125 plain washer flat washer

The Importance of High-Quality DIN 125 Plain Washers

In the realm of construction, manufacturing, and mechanical engineering, the importance of reliable fasteners cannot be overstated. Among these, washers play a crucial role in ensuring the integrity and durability of assembled structures and machinery. Specifically, DIN 125 plain washers (or flat washers) represent a standard solution to a variety of fastening challenges. In this article, we delve into the significance of high-quality DIN 125 plain washers, their applications, and the benefits they offer.

What are DIN 125 Plain Washers?

DIN 125 plain washers are standardized flat washers that conform to the German Institute for Standardization (Deutsches Institut für Normung, or DIN) specifications. Typically crafted from materials such as steel, stainless steel, or plastic, these washers serve multiple purposes, including load distribution, preventing wear, and acting as spacers. Their flat design is essential for providing a stable surface that helps enhance the effectiveness of the fastening system.

Applications of DIN 125 Plain Washers

The versatility of DIN 125 plain washers allows them to be used in a multitude of applications across various industries. Some common uses include

1. Construction In construction projects, plain washers help to secure structural components, such as beams and columns, ensuring that they remain firmly in place. They are often used in conjunction with bolts and nuts to provide increased stability.

2. Automotive The automotive industry frequently employs DIN 125 washers in the assembly of vehicles. These washers are vital for enhancing the connection between various components, such as engine parts, chassis, and suspension systems, ensuring long-lasting performance.

3. Manufacturing In manufacturing settings, these washers are essential for machinery assembly. They help to reduce friction between parts and prevent loosening over time, thereby enhancing the reliability of machinery that operates at high speeds and loads.

4. Electronics In the electronics sector, specially coated or insulated DIN 125 washers can be used to prevent electrical contact between parts, thus protecting sensitive components from short circuits.

high quality din125 plain washer flat washer

Why Choose High-Quality Washers?

Selecting high-quality DIN 125 plain washers is paramount to achieving optimal performance in any application. Here are some reasons why quality matters

1. Durability High-quality washers are made from superior materials that resist wear and corrosion. This is particularly important in environments exposed to moisture, high temperatures, or chemicals. Investing in top-notch washers can significantly extend the lifespan of the assembly.

2. Load Distribution Quality washers ensure proper load distribution across surfaces, reducing the risk of component failure due to excessive pressure on a single point. This is crucial in applications where structural integrity is a priority.

3. Preventing Loosening One of the primary functions of washers is to prevent fasteners from loosening over time. High-quality washers have better resistance to deformation and movement, thereby maintaining tension in the assembly and reducing the likelihood of failure.

4. Cost-Effectiveness Although high-quality washers may come with a slightly higher initial cost, they can ultimately save money by reducing maintenance and replacement costs associated with inferior products. The longevity and performance of quality washers justify the investment.

5. Compliance with Standards Using DIN 125 plain washers ensures compliance with established industry standards, which is essential in sectors where safety and reliability are critical. High-quality washers produced by reputable manufacturers are tested and certified to meet these standards.

Conclusion

In conclusion, high-quality DIN 125 plain washers are indispensable components in various industries, from construction and automotive to manufacturing and electronics. Their ability to enhance the durability, reliability, and efficiency of fastening systems makes them a crucial investment for anyone involved in assembling critical applications. When choosing washers, opting for high-quality materials and reputable manufacturers not only ensures compliance with industry standards but also contributes to the overall success and longevity of any project. Therefore, understanding the value of these seemingly simple components can lead to significant improvements in performance and safety.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024