ก.พ. . 03, 2025 04:31

Back to list

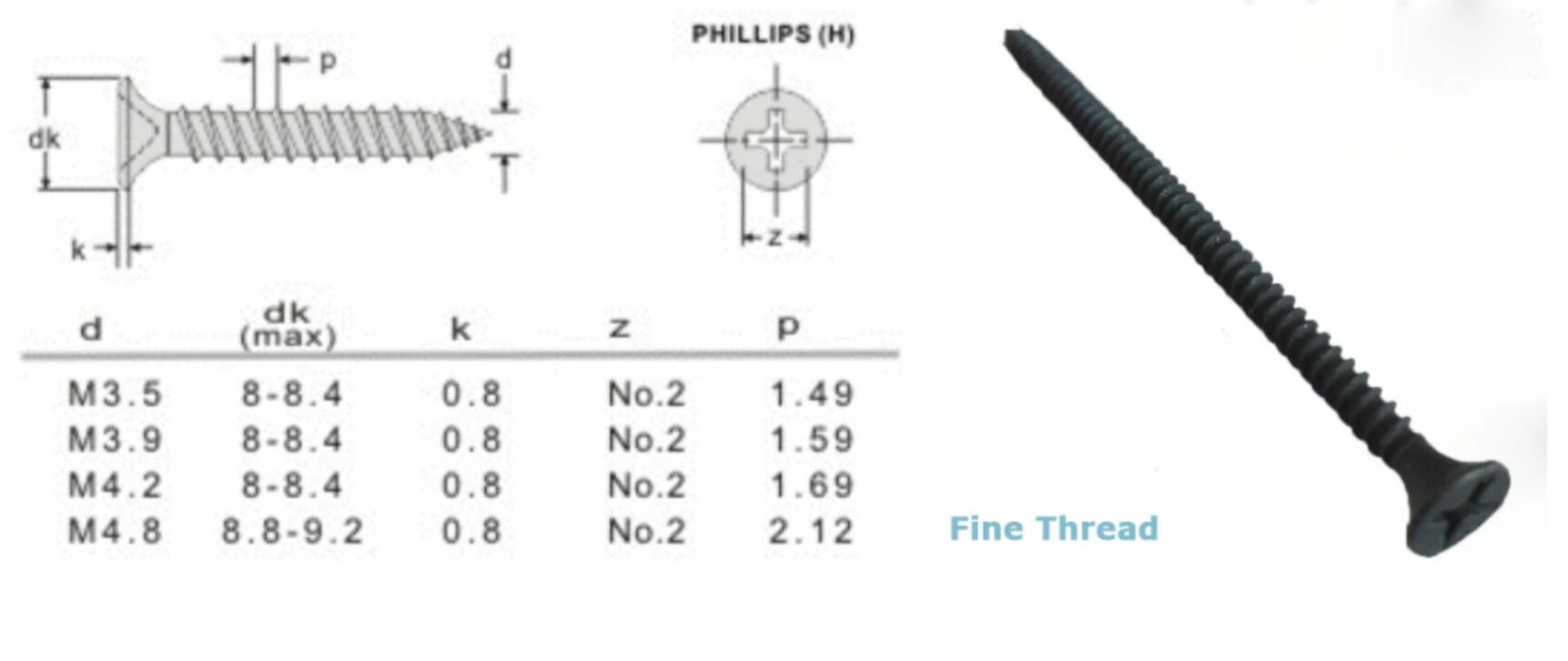

YZP CHIPBOARD SCREW

When embarking on a construction or DIY project involving metal, the importance of choosing the right fasteners cannot be understated. Among the various types of screws available in the market, hex head self-drilling screws stand out for their efficiency and ease of use. These screws are equipped with a drill bit tip that allows for direct drilling into substrates without the need for pre-drilling holes, making them indispensable in metal building projects and roofing applications. Understanding the various sizes of hex head self-drilling screws is crucial to ensure the strength, stability, and longevity of the assembled structure.

Real-world application stories and expert insights underscore the effectiveness of using the right size hex head self-drilling screws. For example, in commercial metal roofing projects, contractors have found that selecting screws with a proper balance of shank diameter and thread pitch can significantly enhance installation speed and reduce labor costs, while also minimizing the risk of water penetration and corrosion by providing a tight, secure seal. Furthermore, expertise in the proper installation techniques is essential. Professionals emphasize the importance of using the correct tools and equipment, such as power screwdrivers with adjustable torque settings, to prevent over-driving which can damage both the fastener and the material. Adopting correct installation methods not only ensures optimal performance but also prolongs the life of the fastened structure. From an authoritative standpoint, understanding the manufacturing standards and quality control processes behind hex head self-drilling screws is critical. Reputable manufacturers adhere to industry standards such as the American Society for Testing and Materials (ASTM) specifications, which ensure that screws meet rigorous performance and durability criteria. Trustworthy manufacturers will provide detailed product information, including mechanical properties, corrosion resistance ratings, and recommended applications, allowing buyers to make informed decisions. In conclusion, the size and specifications of hex head self-drilling screws are pivotal to the success of a project. By balancing shank diameter, length, and thread design with expert installation practices, project managers and DIY enthusiasts alike can achieve secure, efficient, and durable results. With the backing of industry standards and authoritative insights, choosing the right screw not only imparts trust but also fulfills the functional demands of contemporary construction and metalworking applications.

Real-world application stories and expert insights underscore the effectiveness of using the right size hex head self-drilling screws. For example, in commercial metal roofing projects, contractors have found that selecting screws with a proper balance of shank diameter and thread pitch can significantly enhance installation speed and reduce labor costs, while also minimizing the risk of water penetration and corrosion by providing a tight, secure seal. Furthermore, expertise in the proper installation techniques is essential. Professionals emphasize the importance of using the correct tools and equipment, such as power screwdrivers with adjustable torque settings, to prevent over-driving which can damage both the fastener and the material. Adopting correct installation methods not only ensures optimal performance but also prolongs the life of the fastened structure. From an authoritative standpoint, understanding the manufacturing standards and quality control processes behind hex head self-drilling screws is critical. Reputable manufacturers adhere to industry standards such as the American Society for Testing and Materials (ASTM) specifications, which ensure that screws meet rigorous performance and durability criteria. Trustworthy manufacturers will provide detailed product information, including mechanical properties, corrosion resistance ratings, and recommended applications, allowing buyers to make informed decisions. In conclusion, the size and specifications of hex head self-drilling screws are pivotal to the success of a project. By balancing shank diameter, length, and thread design with expert installation practices, project managers and DIY enthusiasts alike can achieve secure, efficient, and durable results. With the backing of industry standards and authoritative insights, choosing the right screw not only imparts trust but also fulfills the functional demands of contemporary construction and metalworking applications.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News