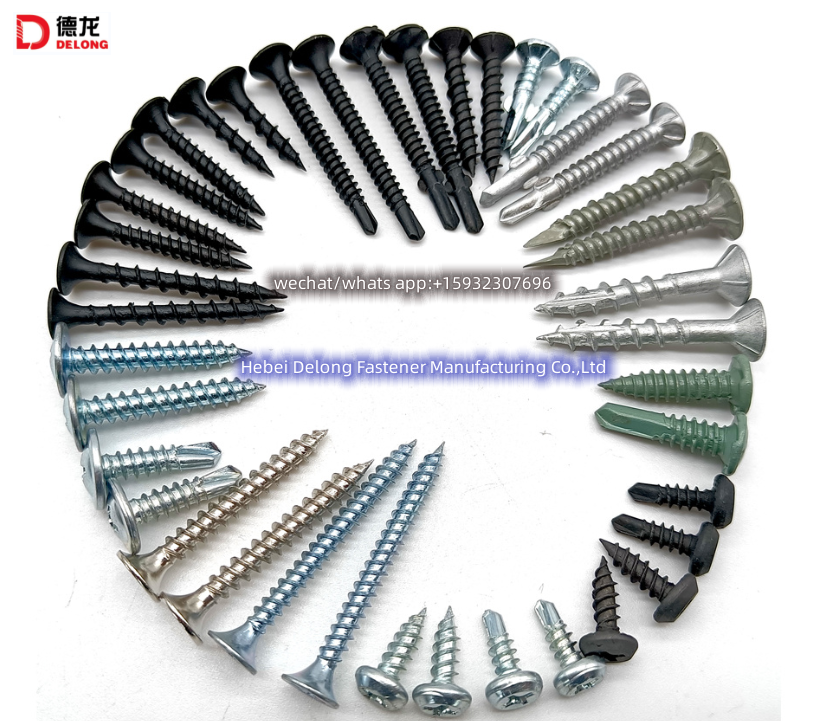

fillister head self tapping screw

Understanding Fillister Head Self-Tapping Screws A Comprehensive Guide

When it comes to fasteners, the choice of screw can significantly impact the strength, durability, and overall success of a project. Among the various types of screws available, fillister head self-tapping screws stand out due to their unique design and functionality. This article delves into the characteristics, applications, advantages, and considerations associated with fillister head self-tapping screws.

What is a Fillister Head Self-Tapping Screw?

A fillister head self-tapping screw features a cylindrical head with a slightly rounded top, resembling a fillister. This design allows for a larger bearing surface, which contributes to better grip and reduces the likelihood of stripping. The self-tapping mechanism means that these screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling in many cases. This property not only saves time but also improves efficiency in various fastening applications.

Characteristics of Fillister Head Screws

Fillister head screws are characterized by several key features

1. Head Design The fillister head provides a larger contact area, which is beneficial for applications requiring a strong hold. It is also aesthetically pleasing, making it suitable for visible areas in finished products.

2. Material Composition Typically made from metals such as stainless steel, carbon steel, or alloy steel, these screws are designed for durability and resistance to corrosion. The choice of material will depend on the intended application and environmental factors.

3. Thread Design Fillister head self-tapping screws come with sharp, pointed threads that enable them to penetrate a variety of materials, including wood, metal, and plastics. Some designs may feature coarse or fine threads, depending on the required hold and the nature of the material being fastened.

4. Drive Types Common drive types include Phillips, slotted, and Torx, which cater to different tools and user preferences. The choice of drive style can affect how easily the screw can be installed or removed.

Applications

Fillister head self-tapping screws are widely used across various industries and applications, including

- Electronics In the assembly of electronic devices, fillister head screws serve to fasten components securely while maintaining a low-profile appearance.

- Automotive These screws are employed in the automotive industry for assembling interior and exterior parts, where strength and aesthetics are critical.

- Construction In building applications, fillister screws offer reliable fastening solutions for wood and metal structures.

fillister head self tapping screw

- Furniture Manufacturers often use fillister head screws to create sturdy connections in furniture, allowing for easy assembly and disassembly

.Advantages

The use of fillister head self-tapping screws presents numerous advantages

1. Time Efficiency The self-tapping feature streamlines the installation process, as there is no need for pre-drilling in many instances.

2. Strong Hold The larger head surface enhances the screw's grip, minimizing the risk of loosening over time.

3. Versatility These screws can be used on various materials, making them suitable for a wide range of applications.

4. Durability With the right material selection, fillister head screws can withstand environmental challenges such as moisture and temperature fluctuations.

Considerations

While fillister head self-tapping screws have numerous benefits, a few considerations should be kept in mind

1. Material Compatibility It is essential to ensure that the selected screw material is compatible with the materials being joined, as different metals can react with each other.

2. Choosing the Right Size The length and diameter of the screw should be appropriate for the materials and thickness involved, as an incorrect size can compromise the connection.

3. Installation Techniques Proper installation techniques must be followed to prevent stripping the screw or damaging the material, especially when working with softer materials.

Conclusion

In summary, fillister head self-tapping screws play a pivotal role in various fastening applications, thanks to their robust design and efficiency. Whether in electronics, automotive assembly, construction, or furniture manufacturing, these screws deliver reliable performance and versatility. By understanding their characteristics and applications, you can make informed decisions when choosing the right screw for your project, ensuring successful outcomes and durable connections.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024