ก.พ. . 10, 2025 11:30

Back to list

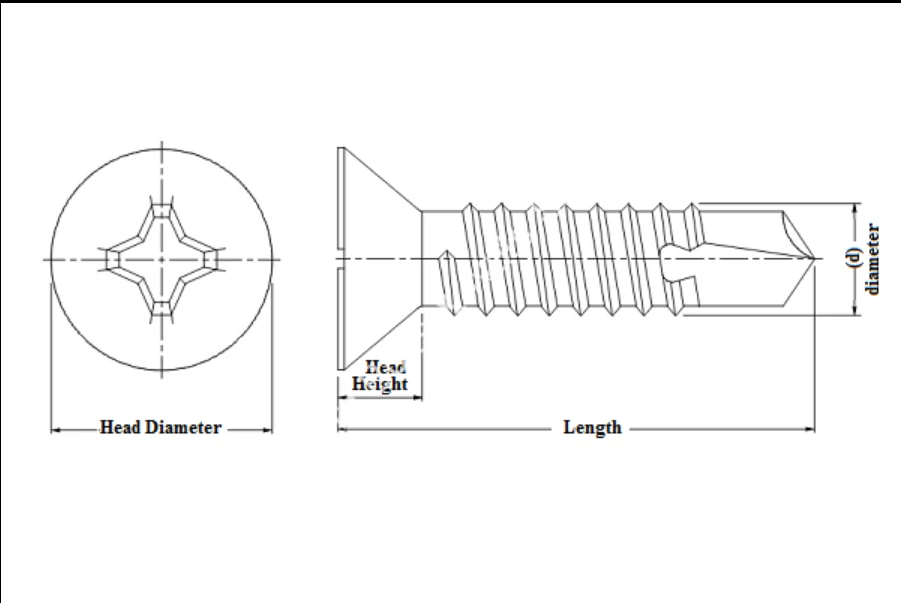

csk head self tapping screw

In the vast world of construction and manufacturing, fasteners hold a place of unparalleled importance. They are the unsung heroes that hold structures together, ensuring safety and durability. Among these, the self-tapping screw stands out for its adaptability and efficiency, especially when dealing with materials ranging from metals to plastics. But what sets the biggest self-tapping screw apart in terms of application and utility?

Authoritativeness in the field of fastening solutions is often a measure of one's ability to create, adapt, and teach. Industry leaders have developed and patented innovative self-tapping screw designs that consistently outperform traditional models. They invest in rigorous testing protocols, ensuring their products meet the highest international standards. Establishing a reputation in this competitive market requires a commitment to quality and education, where sharing insights and breakthroughs earns trust and respect. The leading companies also collaborate with architectural and engineering firms, embedding themselves in state-of-the-art projects to stay ahead of the curve. Trustworthiness in product claims and performance is non-negotiable. Builders must rely on guarantees that the biggest self-tapping screws they choose will not just deliver, but exceed expectations. Transparent labeling, detailed material reports, and consistent customer reviews form the cornerstone of product reliability. Companies that offer lifetime warranties or satisfaction guarantees place their entire brand reputation behind their screws—a testament to their confidence in their product's longevity and performance. To illustrate the real-world impact, consider a recent project where self-tapping screws were pivotal the renovation of historic naval ships. These ships, subject to severe corrosion from years at sea, required replacement fasteners that could withstand similar conditions while maintaining the integrity of the original design. The chosen biggest self-tapping screws were stainless steel with a specialized anti-corrosion coating. The project was completed ahead of schedule, with minimal damage to the aged metalwork, showcasing how the right fastener can streamline complex restoration efforts. In conclusion, the biggest self-tapping screws represent more than just a tool in a builder's arsenal; they embody efficiency, strength, and innovation. Whether it's securing the hull of a massive vessel or holding together components of heavy machinery, these fasteners are indispensable. Understanding their origins, the science behind their design, and the expertise required to select and utilize them effectively is key to leveraging their full potential. As industries continue to demand faster and stronger construction solutions, the role of these versatile screws will only become more pronounced, ensuring they remain a cornerstone in the architecture of modern development.

Authoritativeness in the field of fastening solutions is often a measure of one's ability to create, adapt, and teach. Industry leaders have developed and patented innovative self-tapping screw designs that consistently outperform traditional models. They invest in rigorous testing protocols, ensuring their products meet the highest international standards. Establishing a reputation in this competitive market requires a commitment to quality and education, where sharing insights and breakthroughs earns trust and respect. The leading companies also collaborate with architectural and engineering firms, embedding themselves in state-of-the-art projects to stay ahead of the curve. Trustworthiness in product claims and performance is non-negotiable. Builders must rely on guarantees that the biggest self-tapping screws they choose will not just deliver, but exceed expectations. Transparent labeling, detailed material reports, and consistent customer reviews form the cornerstone of product reliability. Companies that offer lifetime warranties or satisfaction guarantees place their entire brand reputation behind their screws—a testament to their confidence in their product's longevity and performance. To illustrate the real-world impact, consider a recent project where self-tapping screws were pivotal the renovation of historic naval ships. These ships, subject to severe corrosion from years at sea, required replacement fasteners that could withstand similar conditions while maintaining the integrity of the original design. The chosen biggest self-tapping screws were stainless steel with a specialized anti-corrosion coating. The project was completed ahead of schedule, with minimal damage to the aged metalwork, showcasing how the right fastener can streamline complex restoration efforts. In conclusion, the biggest self-tapping screws represent more than just a tool in a builder's arsenal; they embody efficiency, strength, and innovation. Whether it's securing the hull of a massive vessel or holding together components of heavy machinery, these fasteners are indispensable. Understanding their origins, the science behind their design, and the expertise required to select and utilize them effectively is key to leveraging their full potential. As industries continue to demand faster and stronger construction solutions, the role of these versatile screws will only become more pronounced, ensuring they remain a cornerstone in the architecture of modern development.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News