410 stainless steel self drilling screw service

The Advantages of 410 Stainless Steel Self-Drilling Screws A Comprehensive Overview

When it comes to construction and manufacturing, selecting the right fasteners is critical to ensuring the durability and longevity of the project. Among the myriad of options available, 410 stainless steel self-drilling screws have gained considerable popularity due to their unique properties and advantages. This article explores the benefits of using these versatile screws and their applications in various industries.

What Are 410 Stainless Steel Self-Drilling Screws?

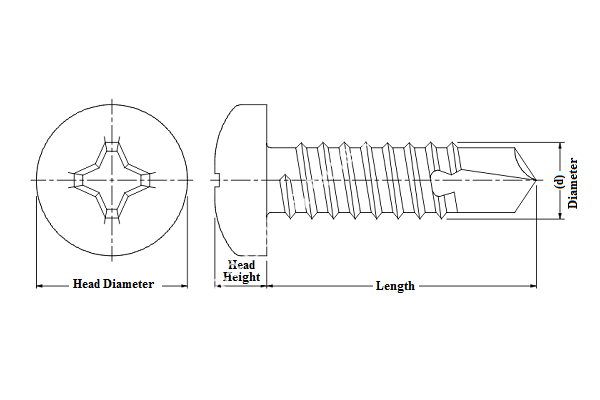

410 stainless steel is a martensitic alloy with a minimum chromium content of 11.5%. This composition provides it with excellent strength, hardness, and wear resistance, making it suitable for demanding applications. Self-drilling screws are specifically designed to eliminate the need for pre-drilling, making fastener installation quicker and more efficient. The drill point at the end of these screws allows them to create their own hole in materials such as metal, wood, or plastics.

Key Benefits

1. Corrosion Resistance One of the standout features of 410 stainless steel is its resistance to corrosion, thanks to its chromium content. This makes these screws highly suitable for applications in environments exposed to moisture and other corrosive elements, such as coastal areas or industrial settings.

410 stainless steel self drilling screw service

2. Strength and Durability 410 stainless steel is known for its impressive hardness and tensile strength. This means that self-drilling screws made from this material can withstand heavy loads and are less likely to shear or break under stress. Their durability ensures long-lasting performance, reducing the need for frequent replacements.

3. Efficiency in Installation The self-drilling feature significantly speeds up the installation process. Traditional screws require a pre-drilled hole, which can be time-consuming and labor-intensive. In contrast, 410 stainless steel self-drilling screws can quickly penetrate a variety of materials, saving both time and labor costs on projects.

4. Versatile Applications These screws find applications in numerous industries, including construction, automotive, HVAC, and manufacturing. Whether it's fastening metal sheets, securing insulation, or assembling furniture, 410 stainless steel self-drilling screws offer the versatility needed for various tasks.

5. Aesthetic Appeal While functionality is crucial, aesthetics also play a role in many projects. The sleek finish of 410 stainless steel screws contributes to a clean and professional appearance, making them suitable for visible applications.

Conclusion

In summary, 410 stainless steel self-drilling screws provide a multitude of benefits that make them an excellent choice for both professionals and DIY enthusiasts. Their corrosion resistance, strength, installation efficiency, versatility, and aesthetic appeal make them a valuable asset in any construction or manufacturing project. As industries continue to seek reliable and long-lasting fastener solutions, the popularity of 410 stainless steel self-drilling screws is likely to grow. Investing in quality fasteners not only ensures project success but also enhances the overall quality and safety of the finished product. Whether you are embarking on a large-scale construction project or a small home improvement task, consider the advantages of these robust and efficient screws.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024