Self-Tapping Socket Head Cap Screw Maintenance and Service Guide

Understanding Self-Tapping Socket Head Cap Screws A Comprehensive Guide

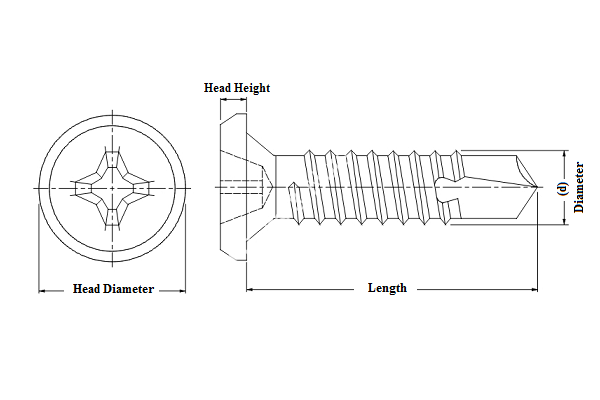

Self-tapping socket head cap screws are specialized fasteners designed for applications where a strong, reliable connection is necessary. These screws combine the features of socket head cap screws and self-tapping capabilities, making them essential in various industries, including manufacturing, construction, and automotive sectors.

What Are Socket Head Cap Screws?

Socket head cap screws are a type of screw characterized by their cylindrical heads and hexagonal recesses. They are designed to be driven by an Allen wrench or a hex key, which provides a robust grip, allowing for high torque applications. This design not only ensures a secure fit but also allows for a more streamlined appearance compared to traditional screws with protruding heads.

The Self-Tapping Feature

The self-tapping capability allows these screws to create their own threads as they are driven into a material. This feature eliminates the need for a pre-drilled hole, saving time and reducing manufacturing steps. Self-tapping screws are particularly useful in materials such as soft metals, plastics, and wood. When selecting a self-tapping socket head cap screw, it’s important to consider the material of the base in which you will be fastening, as this will determine the type of threads and point style best suited for the job.

Advantages of Self-Tapping Socket Head Cap Screws

1. Efficiency The self-tapping mechanism allows for quicker assembly, as there is no need to drill pilot holes. This efficiency reduces labor time and costs, making them ideal for mass production.

self tapping socket head cap screw service

2. Versatility These screws can be used in various applications, from automotive assembly to appliance manufacturing. Their ability to work in different materials expands their usability across various domains.

3. Strength and Reliability The design of socket head cap screws allows for high torque applications, which means that they can withstand considerable force without stripping. This is particularly important in load-bearing applications where safety and durability are paramount.

4. Improved Aesthetics The low profile of the socket head design contributes to a cleaner and more professional appearance in assemblies. This can be particularly valuable in consumer products where design is a critical factor.

5. Corrosion Resistance Many self-tapping socket head cap screws are available in corrosion-resistant materials, such as stainless steel or coated finishes. This ensures longevity and performance, even in harsh environments.

Applications

Self-tapping socket head cap screws can be found in a wide array of applications. In the automotive industry, they are used for attaching components like engine covers and structural parts. In electronics, these screws often secure housings and chassis. Additionally, in furniture assembly, they provide reliable connections that can withstand usage over time.

Conclusion

In conclusion, self-tapping socket head cap screws are an essential component in various industries due to their efficiency, strength, and versatility. Understanding the characteristics, advantages, and applications of these fasteners can help you make informed decisions when selecting components for your projects. Whether you’re an engineer, a technician, or a DIY enthusiast, leveraging the benefits of self-tapping socket head cap screws can enhance the quality and performance of your assemblies.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024