jan . 21, 2025 04:08

Back to list

csk head self tapping screw

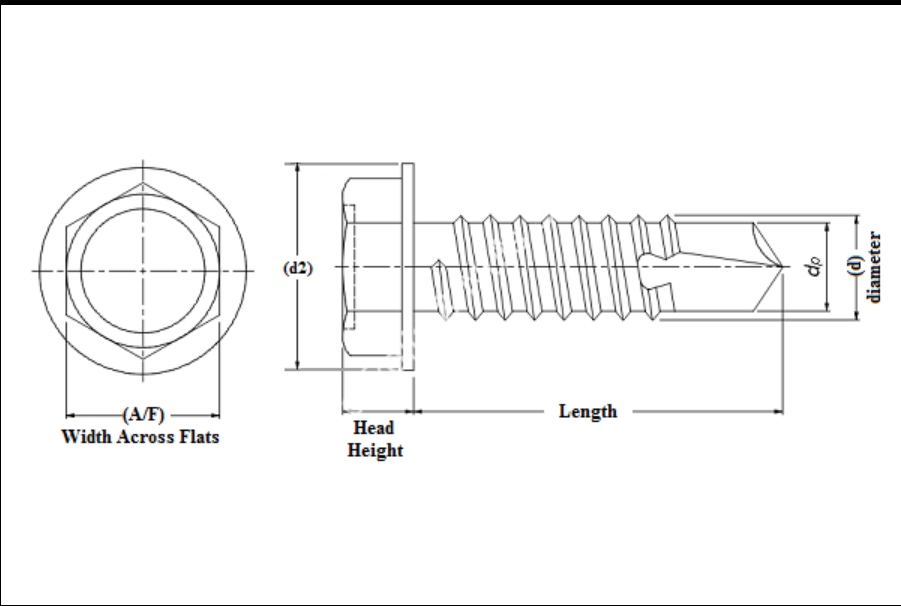

Navigating the world of self-tapping screws can be daunting, especially when faced with the myriad of sizes and specifications available. These versatile fasteners drive into materials without the need for a pre-drilled hole, making them integral to various construction and engineering projects. To optimize your selection process and streamline your projects, understanding the nuances of self-tapping screw size charts is crucial.

From a product perspective, consider the materials and coatings used in self-tapping screws. Stainless steel, often preferred for its corrosion resistance, is ideal for outdoor applications where durability against the elements is paramount. Meanwhile, screws with zinc plating offer excellent resistance to corrosion and are more cost-effective. Real-world experiences accentuate the importance of selecting the right screw. A leading industry case saw a manufacturer selecting screws with incorrect thread counts, resulting in failure under load due to insufficient grip and subsequent catastrophic failures. Rectifying such issues by correctly interpreting the size chart not only salvaged the project but also instilled trust and confidence in their client base. Ideal applications for self-tapping screws include sheet metal constructions, where ease of installation and removal are priorities. These screws are invaluable in automotive assembly, heating and ventilation setups, and even in the assembly of consumer electronics due to their efficiency and reliability. Moreover, ensuring that the integrity of the self-tapping screws is maintained requires stringent adherence to quality standards. Manufacturers adhering to ISO standards and employing rigorous testing routines add an extra layer of credibility and trustworthiness to their offerings. Choosing such products ensures reliability and aligns with the best practices within the industry, enhancing project outcomes and client satisfaction. When choosing a self-tapping screw from a size chart, a holistic approach considering material compatibility, environmental conditions, application requirements, and load characteristics is paramount. Opting for screws designed and manufactured with high precision and high-quality materials guarantees predictability and consistency, reducing potential maintenance interventions and boosting operational efficiency. Ultimately, the key takeaway is simple understanding the trifecta of gauge, length, and thread count, coupled with material and environmental considerations, leads to wise decision-making in selecting the right self-tapping screw. Utilizing comprehensive size charts effectively can save time, reduce costs, and ensure long-lasting, dependable results.

From a product perspective, consider the materials and coatings used in self-tapping screws. Stainless steel, often preferred for its corrosion resistance, is ideal for outdoor applications where durability against the elements is paramount. Meanwhile, screws with zinc plating offer excellent resistance to corrosion and are more cost-effective. Real-world experiences accentuate the importance of selecting the right screw. A leading industry case saw a manufacturer selecting screws with incorrect thread counts, resulting in failure under load due to insufficient grip and subsequent catastrophic failures. Rectifying such issues by correctly interpreting the size chart not only salvaged the project but also instilled trust and confidence in their client base. Ideal applications for self-tapping screws include sheet metal constructions, where ease of installation and removal are priorities. These screws are invaluable in automotive assembly, heating and ventilation setups, and even in the assembly of consumer electronics due to their efficiency and reliability. Moreover, ensuring that the integrity of the self-tapping screws is maintained requires stringent adherence to quality standards. Manufacturers adhering to ISO standards and employing rigorous testing routines add an extra layer of credibility and trustworthiness to their offerings. Choosing such products ensures reliability and aligns with the best practices within the industry, enhancing project outcomes and client satisfaction. When choosing a self-tapping screw from a size chart, a holistic approach considering material compatibility, environmental conditions, application requirements, and load characteristics is paramount. Opting for screws designed and manufactured with high precision and high-quality materials guarantees predictability and consistency, reducing potential maintenance interventions and boosting operational efficiency. Ultimately, the key takeaway is simple understanding the trifecta of gauge, length, and thread count, coupled with material and environmental considerations, leads to wise decision-making in selecting the right self-tapping screw. Utilizing comprehensive size charts effectively can save time, reduce costs, and ensure long-lasting, dependable results.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News