feb . 04, 2025 03:59

Back to list

galvanized csk head self drilling screw

Selecting the right equipment and tools is crucial for any construction project, and the self-drilling screw presents itself as an indispensable component in this regard. With their design facilitating efficiency and strength, self-drilling screws have become a go-to choice for professionals seeking to ensure durability and precision.

Moreover, user experience with self-drilling screws tells a tale of improved productivity and ease-of-use. Builders appreciate how these screws simplify tasks, reduce installation time, and, more significantly, lower the chances of material splitting. Their convenience is not just a matter of an individual component performing its task but an intricate part of a broader ecosystem that maximizes efficiency and returns on time invested. For anyone aiming to stock or utilize self-drilling screws, understanding the various materials and sizes offered is also paramount. Available in a myriad of coatings such as galvanized or stainless steel, these screws can resist rust and corrosion, attributable to their cad-enhanced structural design. This means wherever you are on the globe, you can trust a self-drilling screw to perform optimally in your specific environmental conditions. Feedback from industry veterans highlights the multifaceted advantages of self-drilling screws. Seasoned contractors speak highly of their performance when used in high-speed applications, emphasizing the lower energy consumption patterns compared to traditional methods. This efficiency is not just a cost-saving measure but increasingly a sustainability feature, aligning with global efforts towards environmentally friendly construction practices. As technology continues to advance, the role of innovative fasteners like the self-drilling screw in construction and manufacturing will only grow more significant. They symbolize the perfect blend of classic utility improved through technological advancement. With every twist, these screws not only secure materials together but also secure the position of modern engineering at the forefront of practicality and innovation. Ultimately, whether you are a contractor seeking efficiency or a manufacturer aspiring to offer the best, investing in self-drilling screws with optimized CAD designs will invariably foster reliability, improve operations, and uphold the highest standards of construction and design excellence. This is the future of construction fastening — precise, powerful, and perceptibly perfect.

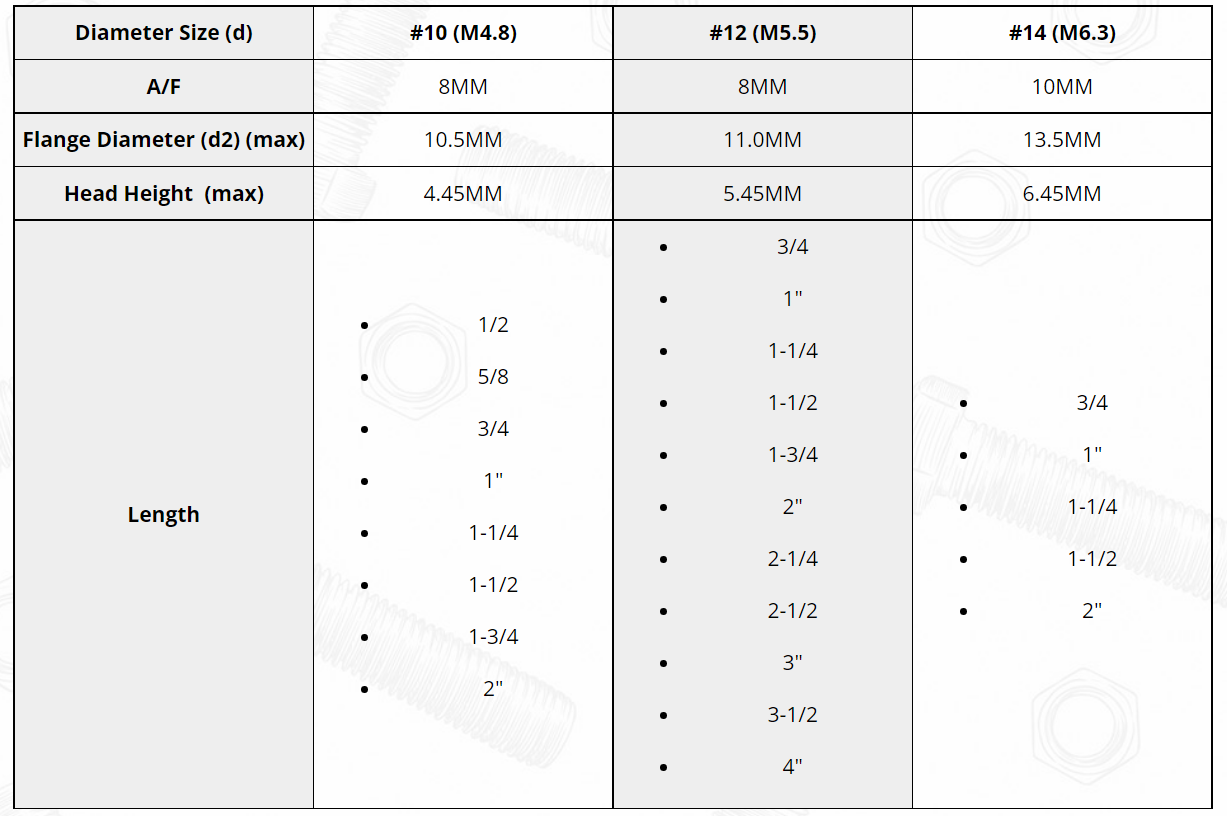

Moreover, user experience with self-drilling screws tells a tale of improved productivity and ease-of-use. Builders appreciate how these screws simplify tasks, reduce installation time, and, more significantly, lower the chances of material splitting. Their convenience is not just a matter of an individual component performing its task but an intricate part of a broader ecosystem that maximizes efficiency and returns on time invested. For anyone aiming to stock or utilize self-drilling screws, understanding the various materials and sizes offered is also paramount. Available in a myriad of coatings such as galvanized or stainless steel, these screws can resist rust and corrosion, attributable to their cad-enhanced structural design. This means wherever you are on the globe, you can trust a self-drilling screw to perform optimally in your specific environmental conditions. Feedback from industry veterans highlights the multifaceted advantages of self-drilling screws. Seasoned contractors speak highly of their performance when used in high-speed applications, emphasizing the lower energy consumption patterns compared to traditional methods. This efficiency is not just a cost-saving measure but increasingly a sustainability feature, aligning with global efforts towards environmentally friendly construction practices. As technology continues to advance, the role of innovative fasteners like the self-drilling screw in construction and manufacturing will only grow more significant. They symbolize the perfect blend of classic utility improved through technological advancement. With every twist, these screws not only secure materials together but also secure the position of modern engineering at the forefront of practicality and innovation. Ultimately, whether you are a contractor seeking efficiency or a manufacturer aspiring to offer the best, investing in self-drilling screws with optimized CAD designs will invariably foster reliability, improve operations, and uphold the highest standards of construction and design excellence. This is the future of construction fastening — precise, powerful, and perceptibly perfect.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News