galvanized self tapping screw company

The Rise of Galvanized Self-Tapping Screw Companies

In the ever-evolving world of construction and manufacturing, fasteners play a pivotal role in ensuring the durability and integrity of structures. Among the various types of fasteners, galvanized self-tapping screws have emerged as a popular choice due to their unique properties and versatility. As a result, the companies specializing in the production of these screws have seen significant growth and innovation.

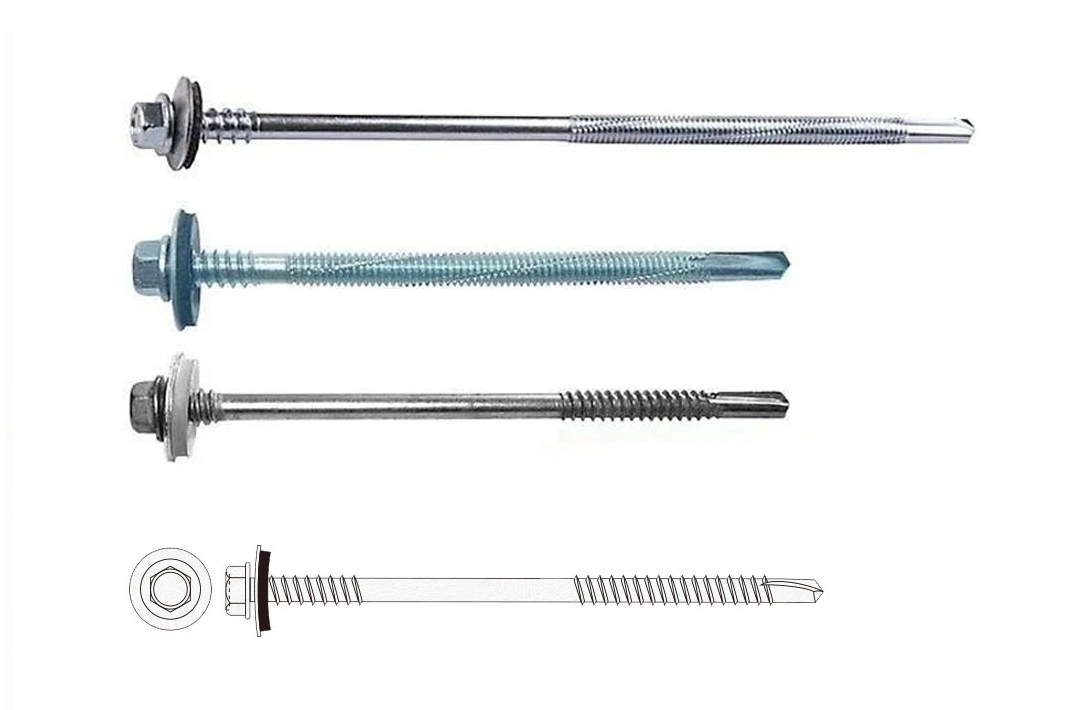

Galvanized self-tapping screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This feature not only saves time but also ensures a more secure fit, making them ideal for a wide range of applications, from metal and wood to plastic. The galvanization process, which involves coating the screws with a layer of zinc, provides enhanced corrosion resistance. This makes them particularly valuable in outdoor or humid environments where rust and degradation could compromise structural integrity.

The increasing demand for these screws can be attributed to several factors. First, the construction industry has been booming in recent years, fueled by urbanization and infrastructure development. Builders and contractors are constantly seeking reliable, durable, and efficient fastening solutions, and galvanized self-tapping screws fit the bill perfectly. Their ability to withstand harsh weather conditions while providing a strong hold makes them a preferred choice for both residential and commercial projects.

galvanized self tapping screw company

Moreover, advancements in manufacturing technologies have allowed companies to produce galvanized self-tapping screws at a higher efficiency and with better quality control. Automation and computer-aided design have streamlined production processes, enabling manufacturers to meet the growing demand without sacrificing quality. This increased efficiency has also led to more competitive pricing, further entrenching their popularity in the market.

Sustainability is another driving force behind the rise of galvanized self-tapping screw companies. As industries move towards eco-friendly practices, the use of recyclable materials in screw production and the longevity of galvanized products align with these efforts. Manufacturers are increasingly focused on sourcing materials responsibly and reducing their environmental footprint, catering to the demands of environmentally-conscious consumers.

In addition, the raw materials and sourcing strategies of these companies have evolved. Many manufacturers are exploring alternative zinc coatings and eco-friendly processes to enhance the sustainability of their products. Innovations in screw design are also being pursued, such as improved thread patterns and head designs, to cater to specific applications and improve performance.

In conclusion, the market for galvanized self-tapping screws is thriving, driven by the growing construction industry, advancements in manufacturing technology, and a shift towards sustainability. As companies continue to innovate and adapt to market demands, the future for galvanized self-tapping screw manufacturers looks promising, marking a significant chapter in the fastener industry.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024