feb . 10, 2025 10:29

Back to list

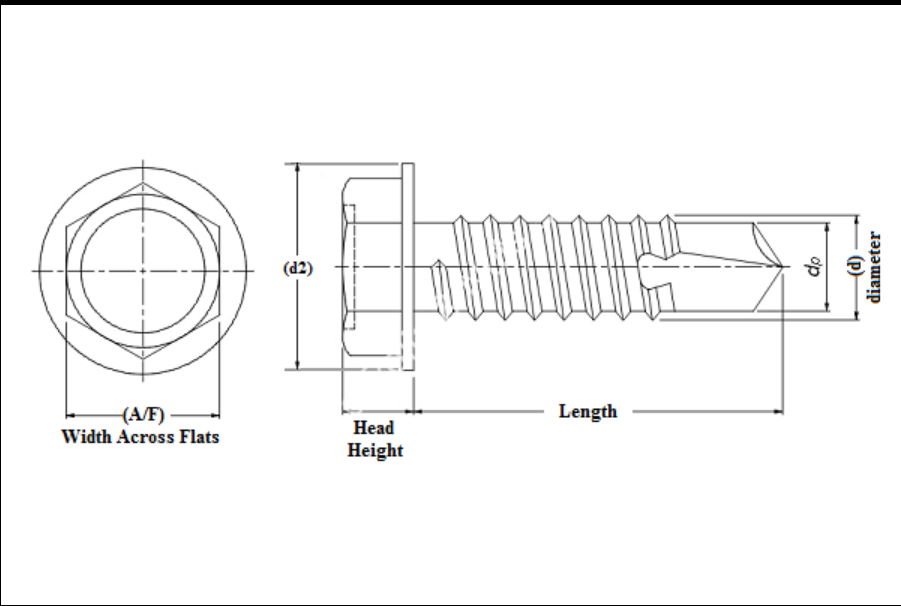

YZP CHIPBOARD SCREW

Selecting the right fastener can make or break a project, especially when considering the demanding requirements of modern construction and manufacturing industries. Among the numerous options available, the 6 x 1 2 self tapping screw stands out as a versatile and effective solution. This article will explore the unique characteristics, applications, and advantages of using this specific type of screw, providing insights drawn from professional experiences and expert knowledge.

The practical application of 6 x 1 2 self tapping screws also extends to electronics, where space and precision are critical. These screws offer the precision needed for securing delicate components without compromising their functionality. Their design ensures stability in environments subjected to vibrations or thermal expansions, making them a trusted choice for securing circuit boards and critical electronic assemblies. Furthermore, one of the critical considerations for experts when choosing fasteners is the material of the screw itself. Self tapping screws are often made from stainless steel or carbon steel, providing excellent resistance to corrosion and wear. This durability means they are suitable for both indoor and outdoor applications, reducing maintenance costs and prolonging the life of the structures they support. Another aspect worth discussing is the environmental impact. By utilizing screws that require no pre-drilling, construction waste is minimized, as fewer mistakes are made, and projects are completed faster. This efficiency contributes to the growing demand for green construction solutions, positioning self tapping screws as an environmentally friendly option without sacrificing performance. In conclusion, the versatility, reliability, and efficiency of the 6 x 1 2 self tapping screw make it a compelling component in any toolkit. Whether for professionals requiring dependable solutions for high-stakes projects or hobbyists aiming for seamless and robust assembly, these screws offer unmatched performance and value. With continued advancements in manufacturing technology, their applicability is set to expand, ensuring that they remain a staple in industries seeking innovation and sustainability.

The practical application of 6 x 1 2 self tapping screws also extends to electronics, where space and precision are critical. These screws offer the precision needed for securing delicate components without compromising their functionality. Their design ensures stability in environments subjected to vibrations or thermal expansions, making them a trusted choice for securing circuit boards and critical electronic assemblies. Furthermore, one of the critical considerations for experts when choosing fasteners is the material of the screw itself. Self tapping screws are often made from stainless steel or carbon steel, providing excellent resistance to corrosion and wear. This durability means they are suitable for both indoor and outdoor applications, reducing maintenance costs and prolonging the life of the structures they support. Another aspect worth discussing is the environmental impact. By utilizing screws that require no pre-drilling, construction waste is minimized, as fewer mistakes are made, and projects are completed faster. This efficiency contributes to the growing demand for green construction solutions, positioning self tapping screws as an environmentally friendly option without sacrificing performance. In conclusion, the versatility, reliability, and efficiency of the 6 x 1 2 self tapping screw make it a compelling component in any toolkit. Whether for professionals requiring dependable solutions for high-stakes projects or hobbyists aiming for seamless and robust assembly, these screws offer unmatched performance and value. With continued advancements in manufacturing technology, their applicability is set to expand, ensuring that they remain a staple in industries seeking innovation and sustainability.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News