Top Manufacturers of Spring Ring Washers in the Industry Today

Exploring the World of Spring Ring Washer Factories

In the realm of mechanical engineering, fasteners play a crucial role in ensuring the durability and stability of various assemblies. Among the diverse range of fasteners, spring ring washers have carved a niche for themselves due to their unique design and functional benefits. This article delves into the intricacies of spring ring washer factories, their manufacturing processes, and their significance in various industries.

Understanding Spring Ring Washers

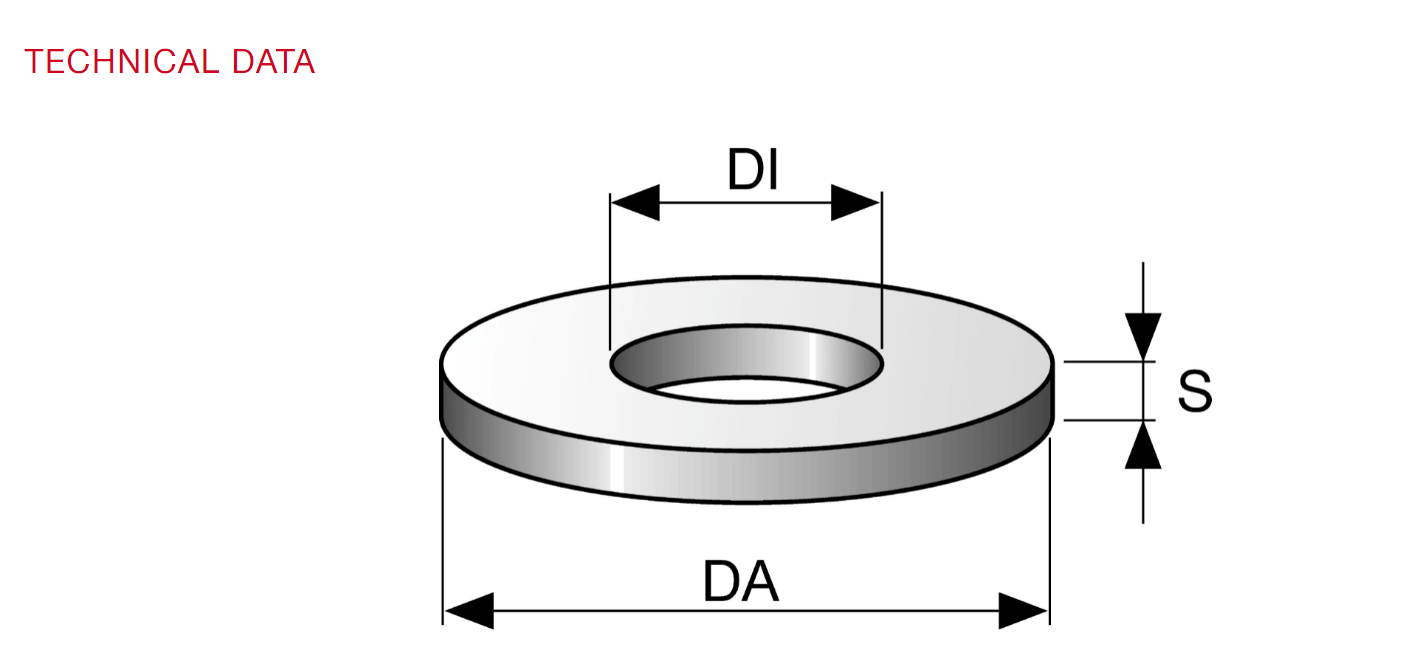

Spring ring washers, also known as wave washers, are circular components designed to provide a spring-like effect. Their main function is to allow for flexibility in the connection of different parts while absorbing shock and compensating for vibrations. Made from materials like stainless steel, plastic, or spring steel, these washers are automatically compressed when installed, thus creating a bolt load that helps maintain assembly integrity over time.

The design of spring ring washers is typically characterized by a wavy geometry. This unique shape allows them to distribute loads evenly and accommodate thermal expansion and contraction in mechanical assemblies. Because of these attributes, spring ring washers are commonly utilized in various applications, including automotive, aerospace, industrial machinery, and electronics.

The Manufacturing Process of Spring Ring Washers

Manufacturing spring ring washers requires precision and expertise. The process generally begins with the selection of high-quality raw materials. Depending on the application, manufacturers might opt for different types of alloy steels or non-corrosive materials such as stainless steel. Once the material is selected, it undergoes machining where it is cut into the required shape and size.

spring ring washer factories

After the initial shaping, the washers are subjected to heat treatment processes to enhance their mechanical properties. Heat treatment helps improve hardness and resilience, ensuring the washers perform well under stress. Following this, the washers are further processed through surface treatments like galvanizing or passivation to increase their resistance to corrosion and wear.

Quality control plays a vital role in the manufacturing of spring ring washers. Factories employ rigorous testing methods, including tensile strength tests, fatigue tests, and dimensional inspections, to ensure that each washer meets the required standards before it is dispatched to clients.

Role of Spring Ring Washer Factories in the Economy

Spring ring washer factories contribute significantly to the economy by providing essential components for various industries. Their products enable enhanced performance and reliability of machinery and products, ultimately leading to improved operational efficiency. In the automotive sector, for instance, the use of high-quality spring ring washers contributes to vehicle safety and longevity, while in the electronics industry, they are vital for ensuring robust connections in circuit boards.

Moreover, spring ring washer manufacturers often focus on innovation and technology, striving to improve their production techniques. This drive for advancement not only leads to better products but also fosters sustainable manufacturing practices, reducing waste and optimizing resource use.

Conclusion

Spring ring washers may seem like small components, yet they play an indispensable role in the functionality and reliability of various systems. The factories that produce these washers harness advanced manufacturing techniques to meet the evolving demands of different industries. With a commitment to quality and innovation, spring ring washer factories are poised to continue their vital contribution to the mechanical engineering domain and beyond. As industries worldwide continue to innovate and expand, the importance of such components will only grow, solidifying spring ring washers as a cornerstone of modern engineering design.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024