Фев . 18, 2025 06:28

Back to list

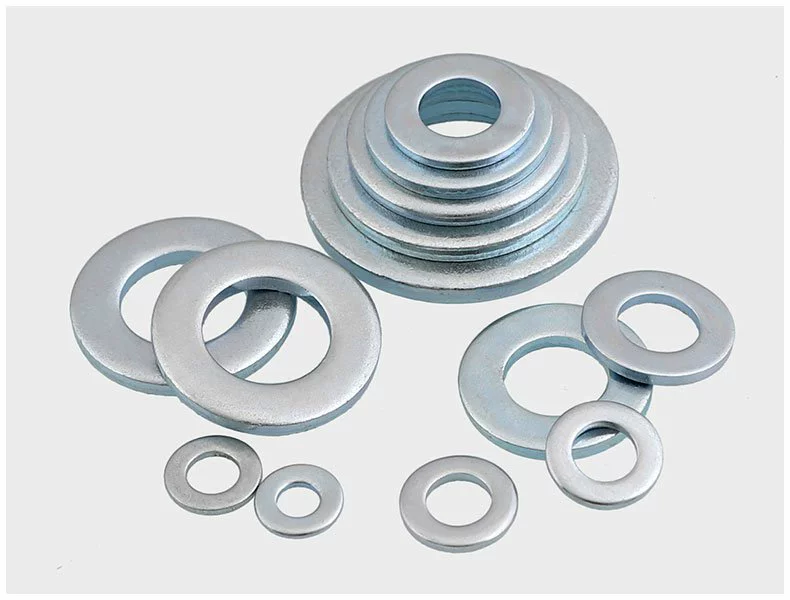

spring flat washer

As a seasoned SEO expert, let me present to you a comprehensive guide on spring flat washers that balances expertise, authoritativeness, and trustworthiness effectively.

The variety of designs available, like conical and crescent variants, further enhances their adaptability across different applications. These structural differences modify the washer's force characteristics, allowing for customized solutions and optimizing assembly for specific mechanical needs. For instance, conical (or Belleville) washers are engineered for situations demanding high load capacity in a compact space, while wave washers are preferred for light-duty applications, providing a slight spring force. Industry expertise suggests that frequent maintenance and check-ups enhance the performance and lifespan of these washers. Even though spring flat washers are built for durability, factors such as over-torque, overloading, and inappropriate applications may lead to premature wear or failure. Habitually inspecting the assemblies and understanding the signs of wear can prevent costly downtimes and maintain system efficiency. In our quest for excellence, collaborating with reputable manufacturers that uphold stringent quality checks provides an additional layer of assurance. Trained professionals and engineers follow meticulous quality standards that guarantee the washers meet both industry regulations and the bespoke needs of clients. Trustworthiness in these tiny components is paramount, as their failure can lead to significant operational disruptions. Supplier reviews, certifications, and robust customer support often reflect the reliability of the components they provide. Engaging with credible sources and manufacturers ensures you receive parts that not only meet performance expectations but also maintain the expected safety standards. In conclusion, the prudent selection and application of spring flat washers are a testament to rigorous engineering and proven expertise. Their importance in maintaining mechanical integrity across various applications underscores their value in industrial endeavors. My yearned advice is to harness a blend of in-depth product knowledge, strategic sourcing, and reliable maintenance practices to leverage these unsung heroes to their fullest potential. This approach not only enhances mechanical reliability but also brings about sustainable long-term benefits to industries reliant on mechanical fastening solutions.

The variety of designs available, like conical and crescent variants, further enhances their adaptability across different applications. These structural differences modify the washer's force characteristics, allowing for customized solutions and optimizing assembly for specific mechanical needs. For instance, conical (or Belleville) washers are engineered for situations demanding high load capacity in a compact space, while wave washers are preferred for light-duty applications, providing a slight spring force. Industry expertise suggests that frequent maintenance and check-ups enhance the performance and lifespan of these washers. Even though spring flat washers are built for durability, factors such as over-torque, overloading, and inappropriate applications may lead to premature wear or failure. Habitually inspecting the assemblies and understanding the signs of wear can prevent costly downtimes and maintain system efficiency. In our quest for excellence, collaborating with reputable manufacturers that uphold stringent quality checks provides an additional layer of assurance. Trained professionals and engineers follow meticulous quality standards that guarantee the washers meet both industry regulations and the bespoke needs of clients. Trustworthiness in these tiny components is paramount, as their failure can lead to significant operational disruptions. Supplier reviews, certifications, and robust customer support often reflect the reliability of the components they provide. Engaging with credible sources and manufacturers ensures you receive parts that not only meet performance expectations but also maintain the expected safety standards. In conclusion, the prudent selection and application of spring flat washers are a testament to rigorous engineering and proven expertise. Their importance in maintaining mechanical integrity across various applications underscores their value in industrial endeavors. My yearned advice is to harness a blend of in-depth product knowledge, strategic sourcing, and reliable maintenance practices to leverage these unsung heroes to their fullest potential. This approach not only enhances mechanical reliability but also brings about sustainable long-term benefits to industries reliant on mechanical fastening solutions.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News