Фев . 11, 2025 11:27

Back to list

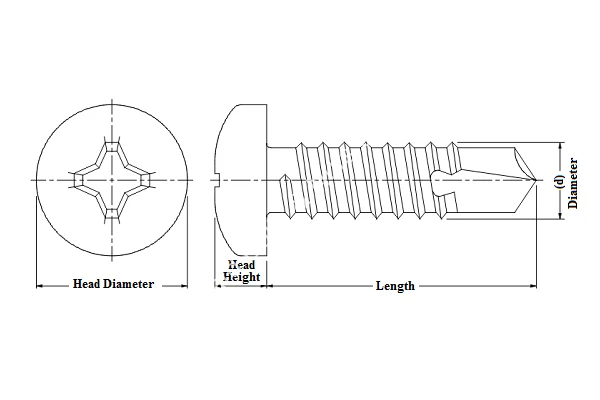

metric self tapping screw dimensions

Navigating the intricate world of fasteners, one encounters numerous options, each with a specific role in construction and design. Among these, metric self-tapping screws hold a distinctive position. When accuracy and durability are critical, understanding the dimensions and functionality of these screws becomes vital.

Application Insights and Professional Expertise In industrial applications, metric self-tapping screws find their niche in environments demanding efficiency and reliability. Their design minimizes inventory by mitigating the need for auxiliary components such as nuts or washers. For assembly lines where speed and repeatability are essential, these screws provide unmatched utility. From an expertise standpoint, the choice of screw dimensions influences not only the mechanical stability but also the long-term resilience of assemblies. Engineers and designers emphasize selecting the correct size and specifications tailored to the material matrix and end-use conditions. Knowledge of substrate density, thermal expansion, and anticipated loads further informs these decisions. Best Practices in Selection and Usage Trustworthiness in construction and manufacturing is anchored in selecting components meeting rigorous quality standards. Metric self-tapping screws must adhere to ISO specifications to assure consistent performance and compatibility across global operations. When implementing these screws, employing calibrated torque tools is recommended to avoid over-tightening, which could compromise material integrity. Additionally, pilot holes, though not always required, can assist in precision alignment, particularly in brittle or fragile substrates. Conclusion Metric self-tapping screws exemplify a blend of engineering prowess and practical application, serving as pivotal elements in modern construction and manufacturing. Their dimensions and specifications cater to a range of applications, offering flexibility and reliability. Capturing the essence of these components—and mastering their application—ensures not only the seamless execution of projects but also the longevity and safety of the resulting structures. This depth of understanding reaffirms their position as indispensable tools for professionals seeking optimal performance and trust in their work.

Application Insights and Professional Expertise In industrial applications, metric self-tapping screws find their niche in environments demanding efficiency and reliability. Their design minimizes inventory by mitigating the need for auxiliary components such as nuts or washers. For assembly lines where speed and repeatability are essential, these screws provide unmatched utility. From an expertise standpoint, the choice of screw dimensions influences not only the mechanical stability but also the long-term resilience of assemblies. Engineers and designers emphasize selecting the correct size and specifications tailored to the material matrix and end-use conditions. Knowledge of substrate density, thermal expansion, and anticipated loads further informs these decisions. Best Practices in Selection and Usage Trustworthiness in construction and manufacturing is anchored in selecting components meeting rigorous quality standards. Metric self-tapping screws must adhere to ISO specifications to assure consistent performance and compatibility across global operations. When implementing these screws, employing calibrated torque tools is recommended to avoid over-tightening, which could compromise material integrity. Additionally, pilot holes, though not always required, can assist in precision alignment, particularly in brittle or fragile substrates. Conclusion Metric self-tapping screws exemplify a blend of engineering prowess and practical application, serving as pivotal elements in modern construction and manufacturing. Their dimensions and specifications cater to a range of applications, offering flexibility and reliability. Capturing the essence of these components—and mastering their application—ensures not only the seamless execution of projects but also the longevity and safety of the resulting structures. This depth of understanding reaffirms their position as indispensable tools for professionals seeking optimal performance and trust in their work.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News