m8 self tapping screw hole size suppliers

Understanding M8 Self-Tapping Screw Hole Size A Guide for Suppliers

When it comes to mechanical and construction applications, the choice of screws and their specifications significantly impacts the overall performance of the assembly. Among the various types of screws, M8 self-tapping screws are widely used due to their efficiency and effectiveness in creating secure joints without the need for pre-drilled holes. Understanding the appropriate hole sizes for these screws is crucial for suppliers, manufacturers, and end-users alike.

What is an M8 Self-Tapping Screw?

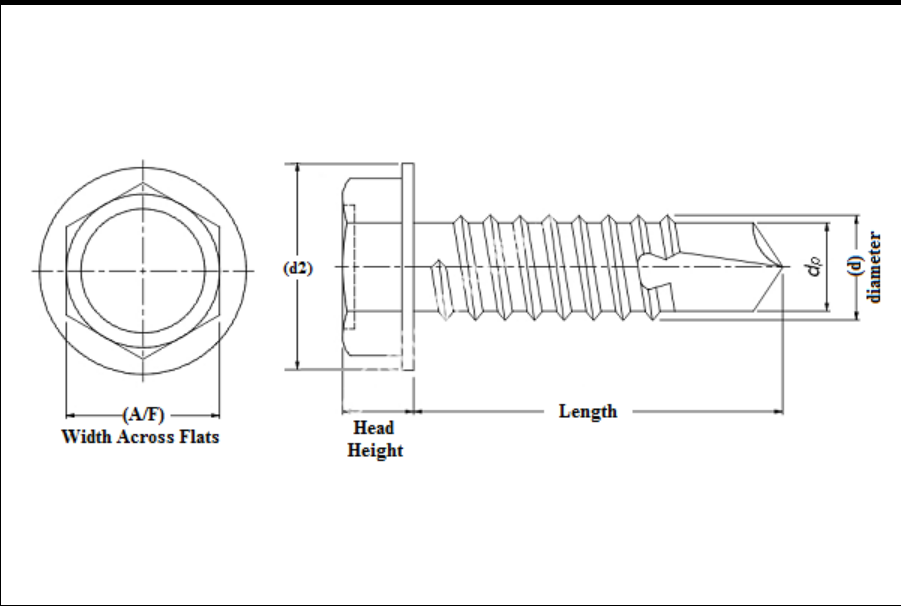

M8 self-tapping screws are designed to cut their own thread while being driven into materials, making them ideal for applications where time and efficiency are paramount. The M refers to metric sizing, and the 8 indicates that the screw has a nominal diameter of 8 millimeters. These screws can be used in various materials, including plastics, wood, and metals, making them versatile for different industrial applications.

Importance of Proper Hole Size

The hole size for an M8 self-tapping screw plays a critical role in ensuring the screw's performance. An incorrect hole size can lead to several issues, including

1. Over-tightening If the hole is too small, using excessive force to drive the screw can damage the material or the screw itself, leading to a failure of the joint. 2. Loose Fitting Conversely, if the hole is too large, the screw may not grip the material adequately, which can result in a loose joint that fails under tension or vibration.

3. Material Integrity An improperly sized hole can compromise the structural integrity of the material being fastened. For example, in thin materials, an oversized hole can lead to breakage or deformation.

Recommended Hole Sizes

m8 self tapping screw hole size suppliers

For M8 self-tapping screws, the recommended hole size varies depending on the type of material being used. Here are some guidelines

- Metal Typically, for metal applications where M8 screws are employed, a pilot hole ranging from 6.5mm to 7.0mm is recommended. This size allows for optimal engagement without over-stressing the screw.

- Wood In wood applications, the hole size can be slightly larger, around 8mm to accommodate the flexible nature of wood fibers. This ensures the screw can grip the fibers effectively while minimizing the risk of splitting.

- Plastic For plastic fittings, the hole size should also be close to the screw's nominal diameter. A hole of approximately 7.5mm may provide the necessary clearance while still allowing the threads to engage properly for a secure fit.

Suppliers and Their Role

As suppliers of M8 self-tapping screws, it is essential to provide detailed specifications regarding recommended hole sizes alongside the screws. This information should be clearly communicated through technical datasheets, catalogues, and online platforms. Furthermore, suppliers should consider offering guidance or support to customers unfamiliar with screw applications, ensuring they understand the implications of using the correct hole size.

Conclusion

Understanding M8 self-tapping screw hole sizes is critical for ensuring the quality and durability of mechanical assemblies. As suppliers, providing accurate specifications and guidance can significantly enhance customer satisfaction and product performance. By promoting best practices regarding hole sizes, suppliers not only help avoid common installation mistakes but also contribute to the overall success of their customers’ projects. As the demand for high-quality fastening solutions continues to grow, suppliers must prioritize education and support in this vital aspect of mechanical design.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024