Manufacturers of Hex Flange Head Self-Tapping Screws for Various Applications

Hex Flange Head Self-Tapping Screw Manufacturers An Overview

In the realm of fasteners, hex flange head self-tapping screws are gaining significant traction due to their unique design and functionality. These screws are engineered to create their own mating thread when driven into materials such as metal, wood, or plastic. This self-threading capability eliminates the need for pre-drilled holes, making them an efficient choice for various applications. As such, the demand for high-quality manufacturers of these specialized screws is on the rise.

Understanding Hex Flange Head Self-Tapping Screws

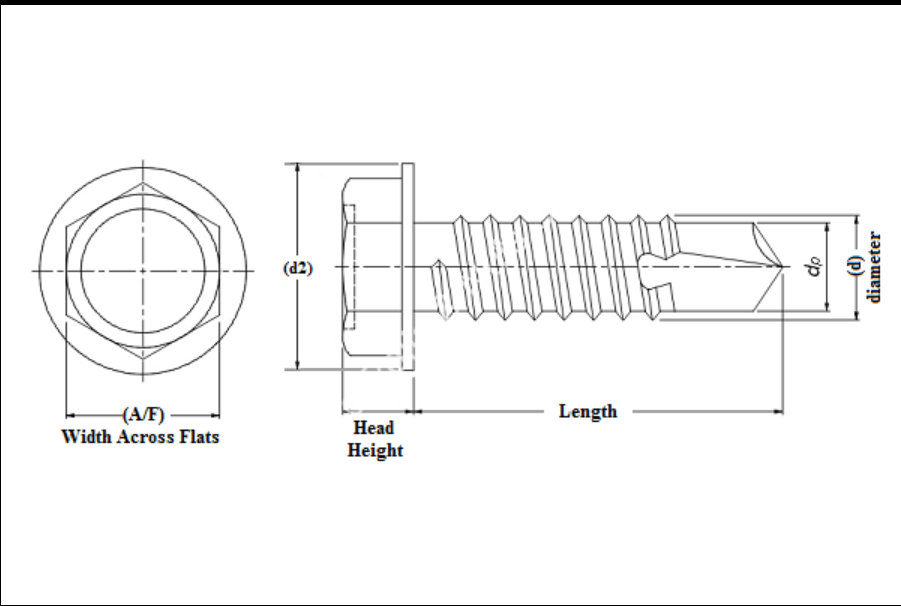

Hex flange head self-tapping screws feature a hexagonal head that allows for easy installation using a standard wrench or socket. The flange around the head increases the bearing surface area, providing enhanced grip and stability when fixed into place. This design lessens the risk of stripping the screw hole and ensures a secure fit, making them ideal for heavy-duty applications. The self-tapping mechanism of these screws allows them to penetrate through surfaces effortlessly, which is particularly beneficial in assembly line processes where efficiency is key.

Applications in Various Industries

These versatile screws are widely used across multiple industries, including automotive, construction, and manufacturing. In automotive production, they ensure secure attachments of various components, while in construction, they are utilized for joining metal sheets and other materials. Their ability to withstand vibrations and resist loosening makes them essential in high-stress applications, such as in machinery and structural frameworks.

The Role of Manufacturers

Manufacturers of hex flange head self-tapping screws play a crucial role in ensuring quality and performance

. The production process involves selecting high-grade materials such as stainless steel, carbon steel, or alloy steel, which contribute to the durability and strength of the screws. Advanced manufacturing techniques, including precision machining and heat treatment, are employed to enhance the properties of the screws, ensuring they can withstand various environmental factors such as corrosion and wear.Criteria for Choosing a Manufacturer

hex flange head self tapping screw manufacturers

When selecting a manufacturer for hex flange head self-tapping screws, several factors need to be considered

1. Quality Control Look for manufacturers that adhere to strict quality standards. Certifications such as ISO 9001 demonstrate a commitment to maintaining high-quality production processes.

2. Customization Options Depending on the project requirements, custom sizes, coatings, and materials may be necessary. Manufacturers that offer these services can provide better solutions tailored to specific applications.

3. Experience and Expertise Experienced manufacturers are more likely to understand industry standards and customer needs. They can provide insights into the best practices for using and installing their products.

4. Customer Support Reliable customer service can enhance the purchasing experience. Manufacturers should be ready to answer queries and provide after-sales support.

5. Reputation in the Market Researching customer reviews and testimonials can give insights into a manufacturer's reliability and quality.

Conclusion

Hex flange head self-tapping screws are vital components in various industrial applications. The manufacturers of these screws must prioritize quality, innovation, and customer satisfaction to meet the growing demands of their respective industries. With the right manufacturer, businesses can ensure they are equipped with reliable fastening solutions that contribute to the efficiency and durability of their projects. As technology and manufacturing processes advance, the potential for hex flange head self-tapping screws continues to expand, promising a bright future for this essential fastener type.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024