drill bit for self drilling screw service

Understanding Drill Bits for Self-Drilling Screw Applications

In the world of construction and manufacturing, self-drilling screws have become an essential fastening solution, particularly in metal and structural applications. The efficiency of these screws is heavily reliant on the drill bits used during the installation process. This article will delve into the specifics of drill bits tailored for self-drilling screws, exploring their types, uses, and the importance of selecting the right bit for optimal performance.

What are Self-Drilling Screws?

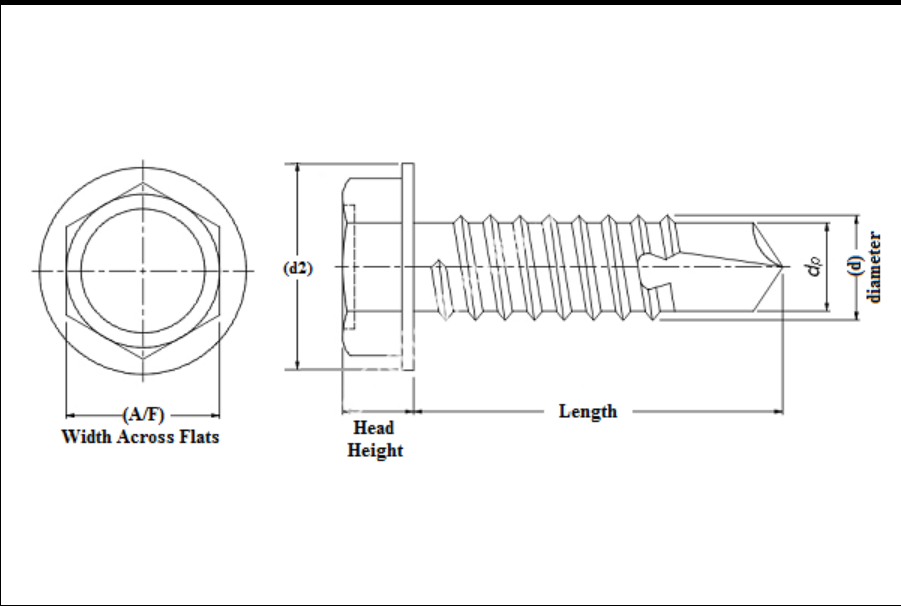

Self-drilling screws, often referred to as Tek screws, are designed with a built-in drill point that allows them to penetrate materials without the need for a pre-drilled hole. This feature significantly enhances efficiency during assembly and construction, making them popular in roofing, siding, metal framing, and other applications. Their ability to self-tap into a variety of materials, including steel, aluminum, and wood, further boosts their utility across different sectors.

The Role of Drill Bits

While self-drilling screws come with their own drill points, there are instances where a separate drill bit is advantageous. This is especially true when working with harder materials or when a greater degree of control is needed. The choice of the drill bit can significantly affect the installation process, influencing factors such as torque, speed, and hole accuracy.

Types of Drill Bits for Self-Drilling Screws

1. High-Speed Steel (HSS) Bits These bits are commonly used for drilling into softer metals and wood. They can handle heat well, making them a popular choice in various applications. However, they may not be suitable for very hard materials.

2. Cobalt Bits Manufactured with a higher percentage of cobalt, these bits are more durable and heat-resistant than standard HSS bits. They are ideal for drilling into harder metals like stainless steel or hardened steel, providing longevity and precision in tough materials.

drill bit for self drilling screw service

3. Carbide-Tipped Bits For the hardest materials, carbide-tipped drill bits are the best option. They can hold an edge much longer than HSS or cobalt bits, making them particularly useful in industrial settings where consistent quality and durability are crucial.

4. Titanium-Coated Bits These bits are coated with titanium to enhance their strength and reduce friction. While they are not as tough as carbide bits, they offer a good balance of durability and cost-effectiveness for general-use applications.

Choosing the Right Drill Bit

Selecting the most suitable drill bit for self-drilling screws involves considering several factors

- Material Type Understanding the material being drilled is critical. Softer materials may only require HSS bits, while harder metals might necessitate cobalt or carbide-tipped bits.

- Screw Size and Type The diameter and length of the screw dictate the size of the drill bit needed. A bit that is too small may not create an adequately sized hole, leading to improper screw placement, while a bit that is too large can result in a weak connection.

- Application The specific application also impacts the choice; for instance, outdoor or structural applications may require bits that can withstand varying environmental conditions.

Conclusion

In summary, while self-drilling screws offer unparalleled convenience in fastening tasks, the choice of drill bit remains crucial for ensuring optimal performance. High-speed steel, cobalt, carbide-tipped, and titanium-coated drill bits each have their unique advantages and are suited for different materials and applications. When installing self-drilling screws, selecting the right drill bit not only enhances efficiency but also ensures the integrity and longevity of the fastened structure. As construction and manufacturing demands continue to evolve, understanding and utilizing the correct drill bits will remain essential for achieving reliable results in any project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024