best conical spring washer

Understanding Best Conical Spring Washers A Comprehensive Overview

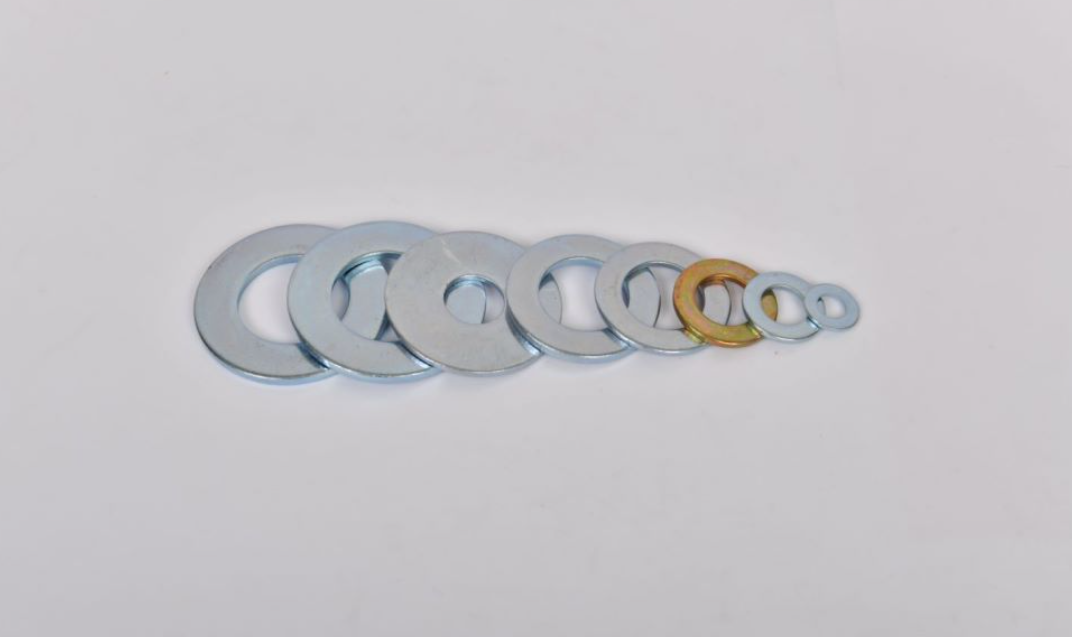

Conical spring washers, known for their unique shape and efficient performance, are essential components in various mechanical and structural applications. Their distinct design—including a tapered, conical form—provides several advantages that set them apart from traditional flat washers.

What is a Conical Spring Washer?

A conical spring washer is a type of fastening device made from resilient materials, often steel or stainless steel, designed to maintain tension and provide load distribution. The washer's conical shape allows it to compress and expand during application, effectively accommodating changes in load and ensuring a secure connection between components.

Applications of Conical Spring Washers

These washers are widely used in a range of sectors, including automotive, aerospace, and construction industries. They are particularly beneficial in applications where vibrations or dynamic loads are present, as they can absorb shock and prevent loosening over time. In automotive assemblies, for example, conical spring washers help maintain the integrity of joints in engines and suspension systems, where fluctuations in pressure and movement are common.

Advantages of Conical Spring Washers

1. Load Distribution The conical design allows for more effective load distribution compared to flat washers. This characteristic helps in minimizing stress concentrations on the surface of the components, ultimately prolonging their lifespan.

best conical spring washer

2. Locking Mechanism When tightened, the washer compresses and exerts an outward force that creates friction against the mating surface. This locking feature is crucial in preventing nut and bolt loosening due to vibrations or dynamic forces.

3. Compensating for Tolerances Conical spring washers can effectively compensate for varying tolerances in bolt and nut assemblies, ensuring a more secure fit. This adaptability makes them ideal for applications where precision is critical.

4. Durability and Corrosion Resistance Many conical spring washers are made from high-grade materials that resist corrosion and wear. This durability is essential in harsh environments, such as marine applications or high-temperature settings.

Choosing the Right Conical Spring Washer

When selecting a conical spring washer, several factors need to be considered, including size, material, load ratings, and the specific application requirements. A proper fit is crucial; too loose a washer may not provide adequate locking force, while a washer that is too tight might not function effectively.

Additionally, it is vital to consider the environmental conditions of the application. For example, in corrosive environments, opting for stainless steel or coated washers can enhance longevity and performance.

Conclusion

Conical spring washers are invaluable components in various engineering applications. Their design offers distinct advantages, including improved load distribution, a built-in locking mechanism, and tolerance compensation, making them the preferred choice in scenarios involving dynamic loads and potential vibrations. Whether in automotive, aerospace, or construction, understanding the importance and functionality of these washers is essential for engineers and technicians aiming for reliability and efficiency in their projects. By selecting the right conical spring washer, one can significantly enhance the performance and durability of mechanical assemblies.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024