Self-tapping screw 3 8 16 x 1 inch supplier for industrial applications and export

Understanding Self Tapping Screws A 3/8 x 1 Exporter's Perspective

Self tapping screws are a fundamental component in many construction and manufacturing processes, offering a reliable solution to fastening needs. Among various specifications, the 3/8 x 1 self tapping screw is particularly noteworthy due to its versatile application in both industrial and domestic settings. For exporters, understanding the nuances of this product can significantly impact their business operations and market reach.

What are Self Tapping Screws?

Self tapping screws are specialized fasteners designed to create their own mating thread in the material into which they are driven. Made typically of metal, these screws eliminate the need for pre-drilled holes, making them convenient and time-saving. The ability to tap their own threads allows for secure attachment in a diverse range of materials, including wood, plastic, and thin metal sheets.

Specifications of 3/8 x 1 Self Tapping Screws

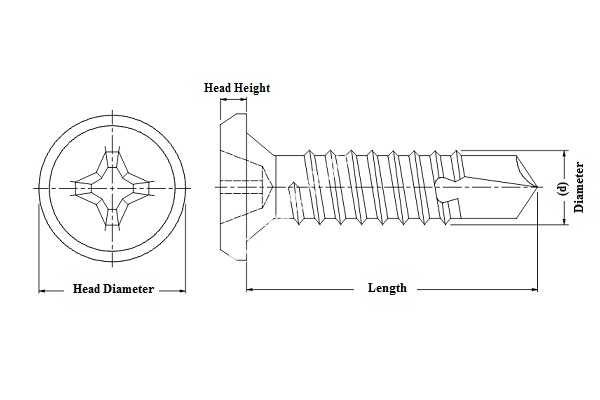

The designation 3/8 x 1 refers to the diameter and length of the screw. The 3/8 diameter provides sufficient strength for various fastening applications, while the 1 length offers versatility in different projects. This size is particularly ideal for light to medium-duty applications, ensuring a strong hold without compromising on workability.

The threads on self tapping screws can vary, including coarse and fine options, depending on the materials they are intended to fasten. Coarse threads are typically used for softer materials, while fine threads are utilized for harder substrates. This adaptability enhances the appeal of 3/8 x 1 self tapping screws in various industries, spurring consistent demand.

Exporting Self Tapping Screws

self tapping screw 3 8 16 x 1in exporter

For exporters, there are critical steps to consider when dealing with self tapping screws, especially the 3/8 x 1. Quality control is paramount; ensuring that the screws meet international standards and are manufactured with durability in mind can set a company apart in the global market. Certification from recognized bodies not only boosts consumer confidence but also adheres to export requirements in various countries.

It is also essential to comprehend the regional demands and preferences. Some markets may prioritize specific materials, such as stainless steel for corrosion resistance, while others might favor cost-effective alternatives like carbon steel. Tailoring product offerings based on these factors can greatly enhance an exporter’s competitive edge.

Packaging and Logistics

Effective packaging is crucial in the exporting process. Self tapping screws should be packaged in a manner that protects them from damage during transit while also being convenient for handling. Bulk packaging versus retail packaging should be determined based on the target market.

Furthermore, logistics should be strategically planned, considering the shipping routes and potential tariffs or trade agreements that may impact costs. Building relationships with reliable shipping partners can streamline the process, ensuring timely delivery and maintaining customer satisfaction.

Conclusion

As demand for self tapping screws, particularly the 3/8 x 1, continues to rise, exporters have a unique opportunity to engage with diverse markets. By focusing on quality, understanding market needs, and optimizing logistics, businesses can successfully navigate the complexities of international trade. In an ever-evolving industry, adapting to trends and maintaining high standards will be key to securing a strong foothold in the global market for self tapping screws.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024