odm pan head self drilling screw din

Understanding ODM Pan Head Self-Drilling Screws According to DIN Standards

In the landscape of modern construction and manufacturing, the importance of quality fasteners cannot be overstated. Among the various types of screws available in the market, ODM pan head self-drilling screws are widely recognized for their efficiency and reliability. This article delves into what ODM pan head self-drilling screws are, their characteristics, and their significance under the DIN (Deutsches Institut für Normung) standards.

What are ODM Pan Head Self-Drilling Screws?

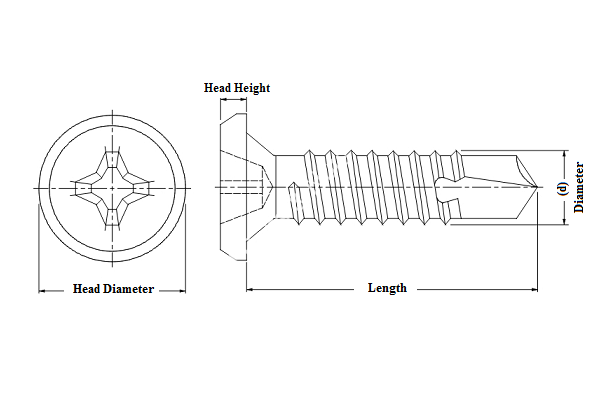

ODM, which stands for Original Design Manufacturer, signifies a type of screw designed to meet specific manufacturing requirements while maintaining the integrity of the work. Pan head self-drilling screws are a favored choice due to their unique design that combines a wide, shallow head with a drill point at the tip. This allows them to create their own hole as they are driven into the material, eliminating the need for pre-drilling.

These screws typically feature a flat underside and a rounded top, which helps distribute the load evenly across the joint. Their self-drilling capability makes them particularly useful in various applications, especially in metal-to-metal and metal-to-wood connections.

Key Features of ODM Pan Head Self-Drilling Screws

1. Self-Drilling Point The distinctive thread design and sharp tip enable these screws to penetrate hard materials without pre-drilling. This feature not only speeds up installation but also reduces labor costs.

2. Pan Head Design The broad head provides a larger bearing surface, which helps prevent the screw from sinking too deeply into the material. It also ensures a cleaner, more polished appearance after installation.

3. Material and Finish ODM pan head self-drilling screws are typically made of carbon steel or stainless steel, offering various finishes such as zinc plating or black oxide. These finishes enhance corrosion resistance, making them suitable for both indoor and outdoor applications.

4. Variety of Sizes and Thread Types These screws come in a range of sizes and thread configurations, offering versatility to accommodate different project needs.

Compliance with DIN Standards

The Deutsches Institut für Normung (DIN) is responsible for setting quality and safety standards for a variety of products, including fasteners. Compliance with DIN standards ensures that screws are manufactured to meet rigorous criteria regarding dimensions, mechanical properties, and performance.

odm pan head self drilling screw din

For ODM pan head self-drilling screws, adherence to DIN standards translates to

- Consistent Quality Each screw produced under these guidelines assures uniformity in size and strength, which is crucial for load-bearing applications.

- Functional Performance DIN standards help guarantee that these screws will perform as expected under various conditions, minimizing the risk of failure during service.

- Safety Assurance Using screws that comply with DIN standards increases the overall safety of the construction or manufacturing project, as it reduces the likelihood of unexpected failures.

Applications in Industry

ODM pan head self-drilling screws are extensively used across various sectors, including construction, automotive, and manufacturing. Their ability to securely join two or more materials quickly makes them ideal for

- Metal Roofing The self-drilling feature simplifies installation, making these screws perfect for attaching metal roofing panels.

- HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, these screws hold ducts and components together efficiently.

- Furniture Assembly The aesthetic appeal of the pan head and the ease of installation make these screws popular in furniture manufacturing.

Conclusion

ODM pan head self-drilling screws are an essential component in modern construction and manufacturing, offering a combination of convenience, efficiency, and reliability. When manufactured to meet DIN standards, they provide added assurance of quality and safety. Whether for industrial use or DIY projects, understanding the capabilities and features of these screws can lead to more successful and durable connections, ultimately contributing to greater project success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024