Custom Zinc Plated Truss Head Self Tapping Screws for Versatile Fastening Solutions

The Versatility and Purpose of Custom Zinc Plated Truss Head Self-Tapping Screws

In the realm of construction and manufacturing, fasteners play a pivotal role in ensuring the structural integrity and longevity of various projects. Among the many types of fasteners, the custom zinc plated truss head self-tapping screw stands out for its unique design and functionality. This article will delve into the characteristics, advantages, and applications of these screws, highlighting their importance in various industries.

Understanding Truss Head Self-Tapping Screws

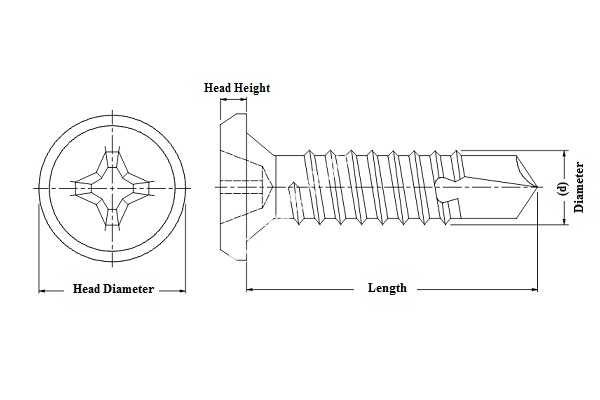

A truss head self-tapping screw is characterized by its broad, flat head that distributes the load evenly over a surface, making it ideal for specific applications where surface contact area is critical. The self-tapping feature allows these screws to create their own hole as they are driven into the material, eliminating the need for pre-drilling. This quality saves time and labor, making installation not only quicker but also more efficient.

Zinc plating is a notable protective finish applied to these screws. This process involves dipping the screws in molten zinc, which provides a protective barrier against corrosion. The zinc coating enhances the longevity of the screw, making it suitable for use in a variety of environments, particularly where moisture exposure is a concern.

The Advantages of Customization

Customizability is one of the key features of truss head self-tapping screws. Manufacturers can tailor these fasteners to meet specific project requirements, allowing for variations in length, diameter, thread type, and head style. This level of customization enables engineers and construction professionals to select the perfect screw for their unique needs, ensuring optimal performance and reliability.

The availability of different lengths and diameters means that custom screws can accommodate various materials, whether they are lightweight plastics or heavy-duty metals. Furthermore, the choice of thread designs can influence the screw's holding power and resistance to loosening under vibration, which is invaluable in machinery and structural applications.

Enhanced Corrosion Resistance

One of the most significant benefits of zinc plating is the increased resistance to corrosion. In environments where screws are exposed to moisture, chemicals, or saline conditions, corrosion can quickly compromise the integrity of a fastener. The zinc coating acts as a sacrificial anode, meaning it will corrode preferentially, thereby protecting the underlying steel. This property significantly extends the lifespan of the screw, making it an ideal choice for outdoor construction, marine applications, and in areas subject to harsh weather conditions.

custom zinc plated truss head self tapping screw

Applications in Various Industries

Truss head self-tapping screws are widely used in a variety of industries, such as

1. Construction In structural and non-structural applications, these fasteners are used to secure framing, decking, and roofing materials. Their ability to create their own hole makes them a popular choice among builders.

2. Automotive The automotive industry relies on self-tapping screws for assembling parts and components. The truss head design provides a lower profile, which is beneficial in applications where space is limited.

3. Electronics In the electronics sector, these screws are used for mounting plastic and metal housings, where their ease of installation and corrosion resistance play a critical role.

4. Furniture Manufacturing The versatility of truss head self-tapping screws allows for secure connections in various types of furniture, from cabinetry to outdoor furniture.

5. HVAC Systems In heating, ventilation, and air conditioning systems, these screws are often used to fasten ductwork and other components, thanks to their reliable performance under various thermal conditions.

Conclusion

In conclusion, custom zinc plated truss head self-tapping screws are essential fasteners in construction and manufacturing. Their innovative design, combined with the protective zinc coating, makes them a reliable choice in a variety of applications, from structural integrity to aesthetic finishing. As industries evolve, the demand for specialized fasteners will continue to grow, and the capability to customize these screws to meet specific needs will remain a vital aspect of their usability. Investing in high-quality fasteners not only ensures the success of a project but also contributes to the durability and safety of the structures they support.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024