high quality self tapping grub screw

Understanding High-Quality Self-Tapping Grub Screws The Unsung Heroes of Fastening

In the vast world of fastening solutions, self-tapping grub screws may not always take center stage, but they are essential components in various industries and applications. These compact screws are designed to create their own mating thread when driven into materials, making them incredibly versatile. This article will delve into what high-quality self-tapping grub screws are, their advantages, applications, and how to select the right product for your needs.

What are Self-Tapping Grub Screws?

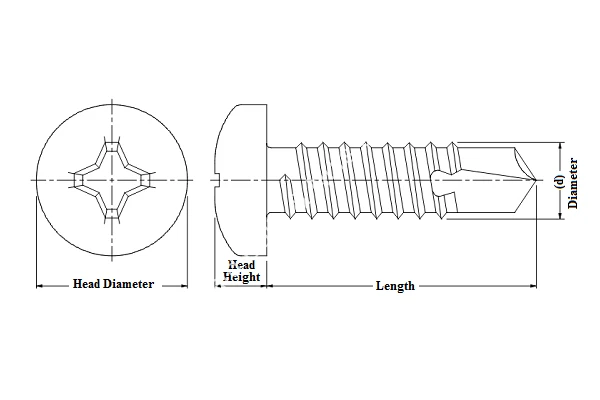

Self-tapping grub screws, also known as set screws, are threaded fasteners that are used to secure an object within or against another object without the need for a nut. Unlike traditional screws, grub screws are designed to tap their own threads into the material as they are installed, which eliminates the necessity for pre-drilling holes. Their unique design often features a blunt end, allowing for easier insertion into components, making them especially useful for holding objects tightly in place.

Advantages of High-Quality Self-Tapping Grub Screws

1. Efficiency One of the primary benefits of using self-tapping grub screws is their ability to create their own thread. This not only saves time during the assembly process but also cuts down on labor costs, as fewer tools and additional steps are required.

2. Versatility High-quality self-tapping grub screws are made from a variety of materials, including stainless steel, alloy steel, brass, and even plastic. This adaptability allows them to be used in different environments, from marine applications to automotive and construction industries, effectively addressing various fastening needs.

3. Strong Grip Quality grub screws provide a robust grip thanks to their threading. When properly installed, they can withstand significant tension and shear forces, ensuring that the components they secure remain in place under various conditions.

4. Corrosion Resistance High-quality grub screws are often coated or made from corrosion-resistant materials. This feature is particularly important in environments that are prone to moisture and chemicals, where traditional screws might fail, leading to potential safety hazards and increased maintenance costs.

5. Customizable Many manufacturers offer customizable options for grub screws, such as different lengths, diameters, and head styles. This flexibility makes it easy to find the perfect screw for specific applications, whether it involves securing a delicate electronic component or supporting heavy machinery.

Applications of Self-Tapping Grub Screws

Due to their versatility and strength, self-tapping grub screws find application in a multitude of industries

high quality self tapping grub screw

- Automotive In vehicles, these fasteners are commonly used to secure different components, such as engine parts, axles, and body panels, ensuring safety and reliability.

- Electronics In the electronics field, they are used to secure circuit boards and other delicate components without risk of damage, making them invaluable in device assembly.

- Furniture Many modern furniture pieces utilize self-tapping grub screws for easy assembly, allowing users to put together flat-pack furniture efficiently and securely.

- Construction In construction, these screws are often used in metal framing and fastening applications, ensuring stability and strength in structures.

Choosing the Right Self-Tapping Grub Screw

When selecting high-quality self-tapping grub screws, consider the following factors

1. Material Choose a material that fits your application needs. For example, stainless steel is great for outdoor use due to its corrosion resistance, while nylon screws can be ideal for lightweight applications.

2. Size Ensure that the size and length of the screw are appropriate for your fastening task. Matching the thread pitch with the material is crucial for effective engagement and maximum holding power.

3. Coating If corrosion is a concern, opt for screws with coatings such as galvanized, zinc-plated, or other protective finishes.

4. Head Style Select a head style that fits your toolset and application requirements, whether it’s a hex, socket, or slotted design.

Conclusion

High-quality self-tapping grub screws play a pivotal role in modern fastening technology. Their efficiency, versatility, and strength make them an ideal choice across various industries. By understanding their advantages and applications, along with making informed choices in selection, manufacturers and DIY enthusiasts alike can ensure they choose the best fastening solutions for their specific needs. In a world where every component contributes to the bigger picture, self-tapping grub screws are indeed the unsung heroes that hold it all together.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024