5 16 x 1 self tapping screw manufacturers

The Importance of 5% 2016 X 1 Self-Tapping Screws in Manufacturing

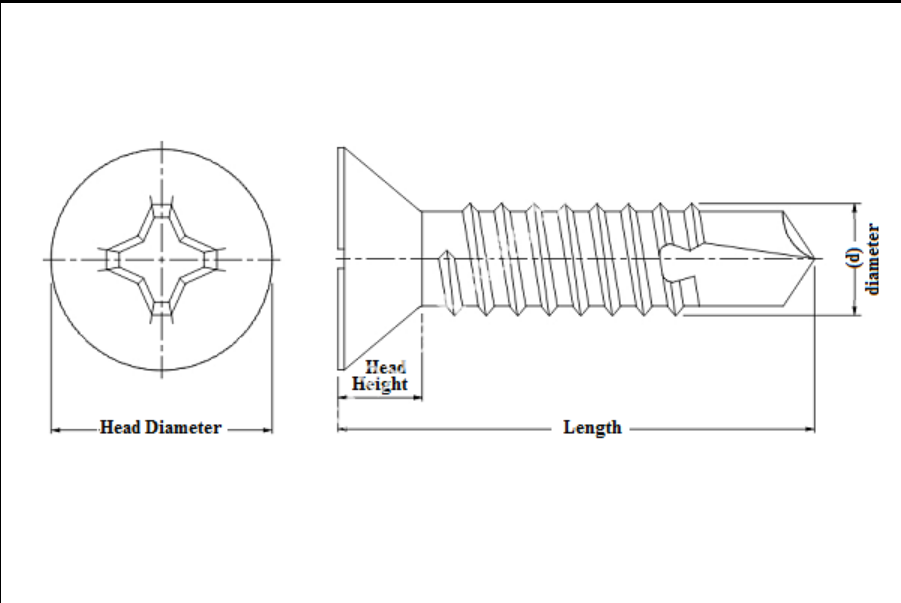

In the world of manufacturing and construction, fasteners play a crucial role in ensuring the stability and durability of structures. Among these fasteners, self-tapping screws are particularly valuable due to their ability to create their own thread as they are driven into materials. One type that stands out is the 5% 2016 X 1 self-tapping screw, which is favored for its robust properties and versatility in various applications.

The designation 5% 2016 X 1 refers to specific characteristics of these screws. The 5% typically denotes the alloy composition, while 2016 indicates the aluminum alloy used in its manufacture, and X 1 signifies the screw's length, which is one inch. Such specifications are crucial for industries seeking reliable components that can withstand demanding conditions.

One of the primary advantages of using self-tapping screws, particularly those made from the 2016 aluminum alloy, is their exceptional strength-to-weight ratio. Aluminum is inherently lighter than steel, yet when alloyed properly, it can acquire impressive tensile strength. This characteristic makes 5% 2016 X 1 self-tapping screws an ideal choice in sectors such as aerospace, automotive, and construction, where weight savings are critical.

5 16 x 1 self tapping screw manufacturers

Moreover, self-tapping screws simplify the assembly process. Unlike traditional screws that require a pre-drilled hole, self-tapping screws can penetrate materials directly, which enhances efficiency during installation. This feature is particularly advantageous in time-sensitive projects or environments where precision and speed are necessary. Industries benefit from reduced labor costs and faster project completion times when utilizing such fasteners.

Another noteworthy aspect of 5% 2016 X 1 self-tapping screws is their corrosion resistance. Aluminum alloys are known for their ability to resist oxidation, which is vital in applications exposed to harsh environmental conditions. This resistance ensures a longer lifespan for the materials being attached and can significantly reduce maintenance costs over time.

The versatility of self-tapping screws extends their use beyond metals; they can also be used with plastic and wood. Whether in residential construction, furniture production, or automotive assembly, these screws adapt well to different materials, showcasing their broad applicability in diverse industries.

In conclusion, the 5% 2016 X 1 self-tapping screw is a prime example of how advanced materials and manufacturing techniques can create components that enhance productivity, reduce weight, and provide durability. As industries continue to look for efficient solutions to enhance their operations, the relevance of such fasteners cannot be overstated. They represent a small yet vital part of the manufacturing puzzle, facilitating strong and lasting connections in various applications. Businesses that prioritize quality fasteners like the 5% 2016 X 1 self-tapping screw will undoubtedly find themselves equipped to meet the challenges of an ever-evolving market.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024