Jan . 13, 2025 12:14

Back to list

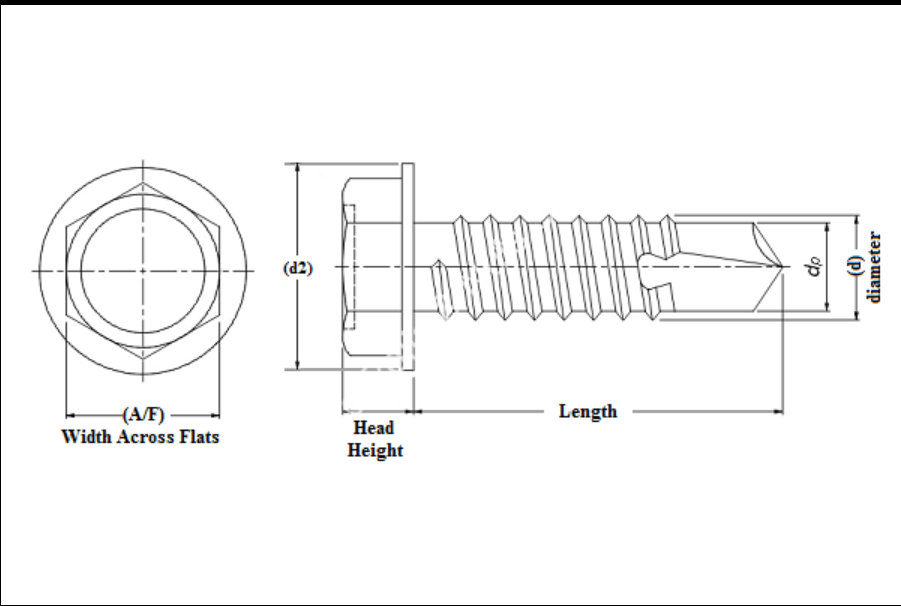

zinc plated truss head self drilling screw

Zinc plated truss head self drilling screws are a cornerstone in many industrial and construction applications, offering a blend of reliability and efficiency that sets them apart. Born from a meticulous design tailored to modern engineering challenges, these fasteners have proven indispensable in projects demanding durability, corrosion resistance, and streamlined installation processes.

Professionals who rely on zinc plated truss head self drilling screws often highlight their trustworthiness and performance consistency. These screws conform to industry standards and regulations, underscoring their credibility as reliable fasteners. In industries where safety and compliance are non-negotiable, such as automotive and aerospace sectors, using screws that offer both mechanical strength and compliance assurance is critical. The expert application of these screws demands an understanding of the specific materials and environmental conditions they will face. Professionals are advised to assess factors such as tensile strength requirements, material compatibility, and environmental exposure prior to selection. Proper installation based on manufacturer guidelines further enhances their effectiveness, ensuring that the longevity and integrity of the entire construction are maintained. In conclusion, zinc plated truss head self drilling screws represent more than just a fastening technique; they are a testament to engineering ingenuity, combining protection, efficiency, and versatility. Their application not only fulfills technical requirements but also aligns with broader goals of sustainability and efficiency within modern construction and manufacturing landscapes. Embracing these screws is a step towards building structures and products that stand the test of time, both functionally and aesthetically.

Professionals who rely on zinc plated truss head self drilling screws often highlight their trustworthiness and performance consistency. These screws conform to industry standards and regulations, underscoring their credibility as reliable fasteners. In industries where safety and compliance are non-negotiable, such as automotive and aerospace sectors, using screws that offer both mechanical strength and compliance assurance is critical. The expert application of these screws demands an understanding of the specific materials and environmental conditions they will face. Professionals are advised to assess factors such as tensile strength requirements, material compatibility, and environmental exposure prior to selection. Proper installation based on manufacturer guidelines further enhances their effectiveness, ensuring that the longevity and integrity of the entire construction are maintained. In conclusion, zinc plated truss head self drilling screws represent more than just a fastening technique; they are a testament to engineering ingenuity, combining protection, efficiency, and versatility. Their application not only fulfills technical requirements but also aligns with broader goals of sustainability and efficiency within modern construction and manufacturing landscapes. Embracing these screws is a step towards building structures and products that stand the test of time, both functionally and aesthetically.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News