Wholesale Self-Tapping Screw Dimensions for Various Applications and Sizes

Understanding Wholesale Self-Tapping Screw Dimensions for Efficient Applications

Self-tapping screws are essential fasteners in various industries, prized for their ability to create their own mating threads in material, offering a robust connection without the need for pre-drilled holes. Understanding the dimensions of wholesale self-tapping screws, often expressed in square meters (m²) for bulk purchases, is crucial for manufacturers, construction firms, and DIY enthusiasts. This article delves into the importance of knowing these dimensions, their standard classifications, and the implications for various applications.

The Importance of Dimensions

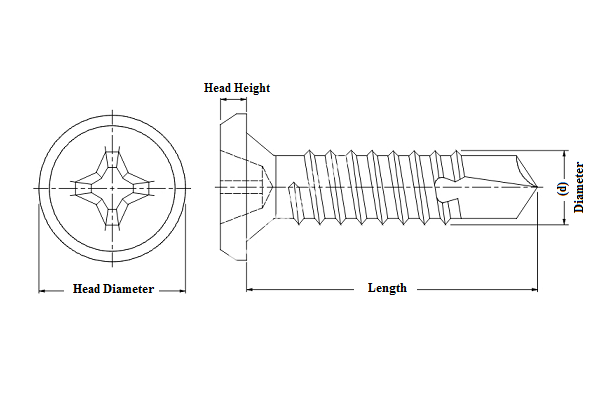

When purchasing self-tapping screws, especially in wholesale quantities, dimensions are key indicators of their suitability for specific projects. The primary dimensions to consider include length, diameter, thread pitch, and head type. These parameters not only affect the screw's fit and holding power but also influence the material's compatibility and the load it can bear.

1. Length The length of a self-tapping screw is the distance from the underside of the head to the tip of the screw. Common lengths range from 6mm to 100mm. For applications involving thicker materials, longer screws are necessary to ensure a strong grip. Conversely, in thinner materials, oversizing can lead to material damage or ineffective fastening.

2. Diameter The diameter of a screw is critical for ensuring that it fits snugly into the drilled hole. Self-tapping screws come in various diameters, typically measured in millimeters. A larger diameter increases the holding power but may require a more extensive initial hole, which can complicate installation. For instance, screws with a diameter of 3.5mm to 7mm are commonly used in wood and metal applications.

3. Thread Pitch The thread pitch refers to the distance between threads, influencing how tightly the screw will grip the material. Different applications may require coarse or fine threads; for instance, coarse threads are ideal for soft materials, while fine threads are better suited for harder materials.

4. Head Type The head style of self-tapping screws varies, with common types including pan, flat, and hex heads. Each style suits different applications; for example, pan heads are often used in areas where a wide bearing surface is essential, while flat heads provide a flush finish.

wholesale m2 self tapping screw dimensions

Classifications Based on Material and Coating

Self-tapping screws can be classified based on the material they are made from and any coatings they may have. Steel screws are common, but stainless steel and brass options are available for environments where corrosion resistance is critical. Additionally, screws may be coated with zinc or other materials to enhance durability.

When buying in bulk (i.e., wholesale), it’s essential to consider these material properties as they directly impact the performance and longevity of the screws in different environments. Recognizing that corrosion-resistant screws are often more expensive can help in budgeting for projects, particularly where high volumes are involved.

Applications

The application of self-tapping screws spans numerous industries, including construction, automotive, and electronics. In construction, they are used for securing walls, fixtures, and fittings. In automotive, self-tapping screws contribute to assembling components while ensuring they can withstand vibration and stress.

DIY enthusiasts often appreciate the ease of use of self-tapping screws, as they eliminate the need for additional hardware or tools while providing secure fastening solutions. However, choosing the correct dimensions for DIY projects can determine the success of a repair or assembly.

Conclusion

An understanding of wholesale self-tapping screw dimensions—length, diameter, thread pitch, and head type—is essential for selecting the right fastener for a specific project. These dimensions affect performance and compatibility across various applications, making it crucial for designers, builders, and hobbyists to be knowledgeable about them. Ultimately, investing the time to choose the right screws can lead to heightened safety, improved performance, and reduced failure rates in construction and manufacturing projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024