wholesale drywall screw schedule

Understanding the Wholesale Drywall Screw Schedule

The construction industry is a bustling arena where precision and quality materials are paramount, particularly when it comes to drywall installation. A crucial yet often overlooked element of this process is the drywall screw. As an essential fastener, drywall screws play a pivotal role in securing drywall sheets to framing while ensuring a smooth finish. To streamline the procurement and usage of these essential materials, understanding a wholesale drywall screw schedule can be significantly beneficial for contractors, builders, and suppliers alike.

What is a Drywall Screw?

A drywall screw is a specially designed fastener that features a flat head and sharp point, to penetrate the material easily without causing damage. Unlike regular screws, drywall screws are coated with a corrosion-resistant substance, making them suitable for various environments. They typically come in different lengths and diameters to accommodate different drywall thicknesses and types of framing materials. Understanding these specifications is essential when crafting a drywall screw schedule.

The Importance of a Drywall Screw Schedule

A drywall screw schedule is a comprehensive outline that details the types and quantities of screws required for a specific drywall installation project. This schedule includes essential information such as screw lengths, types (e.g., coarse or fine threads), and the recommended spacing for installation. Utilizing a well-organized screw schedule brings numerous benefits

1. Efficiency in Planning and Execution A detailed schedule allows contractors to understand exactly how many screws will be needed upfront, minimizing delays caused by last-minute trips to suppliers. This efficiency can significantly affect project timelines and labor costs.

2. Cost Management By determining the exact quantity of screws required, builders can purchase in bulk and take advantage of wholesale pricing, reducing material costs. A good schedule helps prevent over-ordering, which can lead to wasted expenditures.

3. Material Compatibility Different drywall installations might require various types of screws tailored to specific materials. For example, screws designed for metal frames differ from those used for wooden framing. A precise schedule helps ensure the correct fasteners are used for the job, avoiding potential issues during installation.

wholesale drywall screw schedule

4. Quality Assurance Having a structured approach to selecting and using screws can improve overall build quality. Properly scheduled screws reduce the risk of drywall sagging or cracking over time, ensuring that the finished product meets or exceeds expectations.

Components of a Drywall Screw Schedule

A comprehensive drywall screw schedule typically contains the following elements

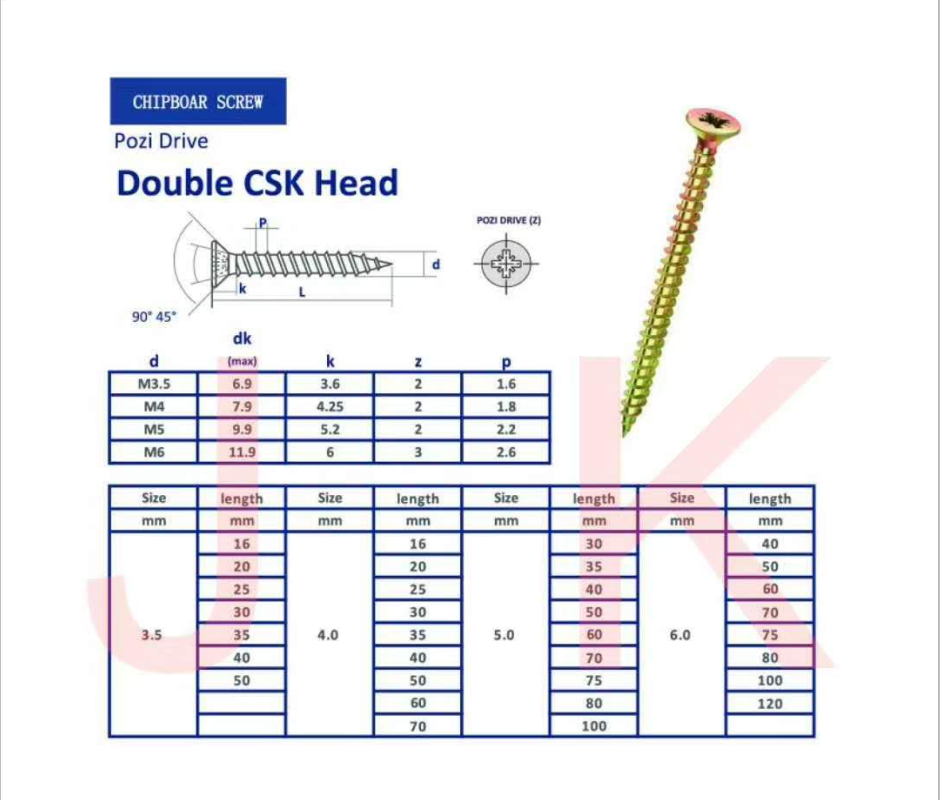

- Type of Screw Identifying whether coarse or fine screws are required based on the materials being used. - Length and Diameter Specifying the appropriate size to accommodate the thickness of the drywall being installed and the underlying frame.

- Quantity Providing the total number of screws needed, calculated based on square footage and installation patterns.

- Installation Instructions Outlining recommended spacing and installation techniques to ensure optimal performance.

- Supplier Information Listing preferred wholesale suppliers to facilitate purchasing decisions.

Conclusion

In the world of drywall installation, a wholesale drywall screw schedule is more than just a list; it is a blueprint for success. By taking the time to craft a detailed screw schedule, contractors can optimize their workflow, manage costs effectively, and ensure that they have the right materials to achieve high-quality results. The role of drywall screws may be small in the grand scheme of construction, but their impact on the integrity and aesthetics of a building is undeniably significant. Thus, proper planning and utilization through a well-structured schedule can make all the difference in any drywall project.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024