Wholesale Metal Flat Washers in Bulk for Various Applications and Industries Available Now

Understanding Wholesale DIN 125 Metal Flat Washers A Comprehensive Guide

In the realm of manufacturing, construction, and various DIY projects, the significance of small components often goes unnoticed. One such essential yet understated component is the flat washer, particularly the DIN 125 metal flat washer. Understanding what these washers are, their specifications, benefits, and significance can greatly enhance both the quality and longevity of your assemblies.

What is a DIN 125 Flat Washer?

The DIN 125 flat washer is a standardized piece of hardware used primarily to distribute the load of a fastener, such as a screw or bolt. The 'DIN' stands for Deutsches Institut für Normung, Germany's national organization for standardization. The '125' refers to a specific standard classification established by this organization. These washers come in various sizes and thicknesses, allowing for a wide range of applications across different industries.

Flat washers, especially those adhering to DIN standards, possess a smooth, flat surface and circular shape, making them ideal for supporting and protecting surfaces while preventing damage caused by tension or compressive loads. Their use extends from automotive applications to construction and electronic devices.

Key Specifications of DIN 125 Washers

DIN 125 washers are typically made from various metals, including stainless steel, carbon steel, and other alloys, making them suitable for different environments. The choice of material influences properties such as strength, corrosion resistance, and thermal conductivity. For instance, stainless steel washers are often employed in outdoor or marine applications due to their superior resistance to rust and corrosion.

The standard specifications mainly dictate the inner diameter, outer diameter, and thickness. Choosing the right size is crucial to ensure a snug fit with the corresponding bolt or screw, eliminating any potential loosening due to vibration or movement.

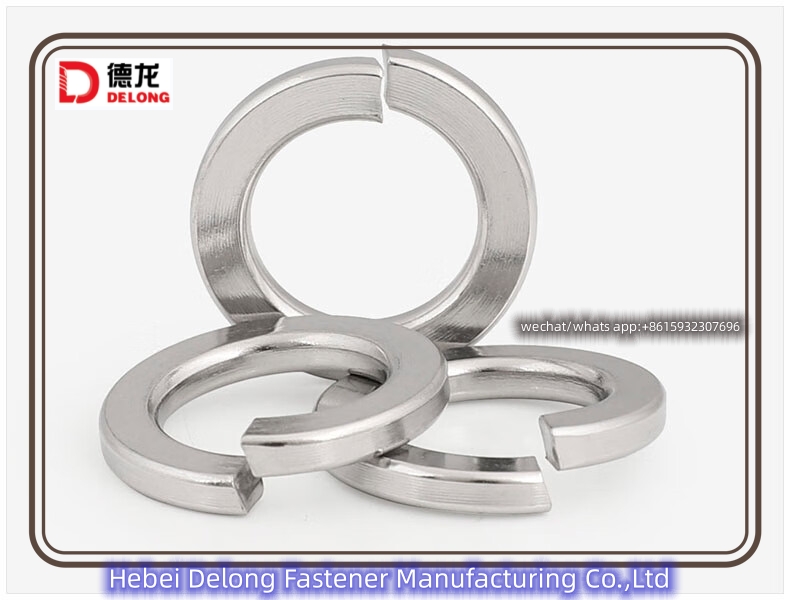

wholesale din125 metal flat washer

Benefits of Using DIN 125 Flat Washers

1. Load Distribution One of the primary benefits of using flat washers is their ability to distribute the load evenly across the surface. This capability helps in reducing the risk of damage to the material being fastened and prevents the fastener from pulling through or damaging the surface.

2. Vibration Resistance In environments with constant vibration, flat washers help prevent fasteners from loosening over time. This property is particularly valuable in automotive, aerospace, and industrial applications, where equipment stability is critical.

3. Protection Washers protect surfaces from abrasion and wear caused by the fastener’s head. They act as a barrier, reducing the chance of scratching or deforming the material underneath the fastener.

4. Cost-Effective When purchased in bulk, particularly through wholesale channels, DIN 125 flat washers are an economical choice for manufacturers and builders. The low cost combined with their durability makes them an ideal component in any assembly.

Conclusion

In conclusion, DIN 125 metal flat washers, though small in size, play a significant role in ensuring the integrity and longevity of various structures and machines. Their ability to distribute load, resist vibration, and provide protection makes them indispensable in countless applications. Whether you are a DIY enthusiast or a professional contractor, understanding the importance of these washers can lead to more effective and safer projects.

When considering purchasing, wholesale options present an excellent opportunity to stock up on these essential components at a fraction of the cost, ensuring you have a reliable supply for any ongoing or future projects. Always remember to choose the appropriate material and size to meet the specific requirements of your application, ensuring optimal performance and longevity.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024