Understanding Drywall Screw Length Codes for Construction Companies and Their Applications in Projects

Understanding Drywall Screw Length Codes and Their Importance in Construction

When it comes to construction and home improvement, the use of the right materials is crucial to ensuring the integrity and durability of the structure. One often overlooked but vital component in drywall installation is the drywall screw. Understanding drywall screw length codes is essential for contractors, builders, and DIY enthusiasts to achieve optimal results.

Drywall screws are specifically designed to attach drywall sheets to framing materials, usually wood or metal studs. They come in various lengths and types, and selecting the appropriate length is critical to ensuring strong and secure attachment. The length of the drywall screw is determined by the thickness of the drywall and the material to which it is being fastened. Generally, for standard 1/2-inch thick drywall, a screw length of 1 1/4 inches to 1 5/8 inches is recommended. For thicker drywall, such as 5/8-inch sheets, a screw length of 1 5/8 inches to 2 inches is ideal.

The code system for drywall screw lengths is not arbitrary; it is guided by industry standards that ensure safety and reliability. The American National Standards Institute (ANSI) and the Gypsum Association have established guidelines that help manufacturers produce screws that meet specific strength and performance requirements. This standardization also enables contractors to select the right screw size for their projects without confusion.

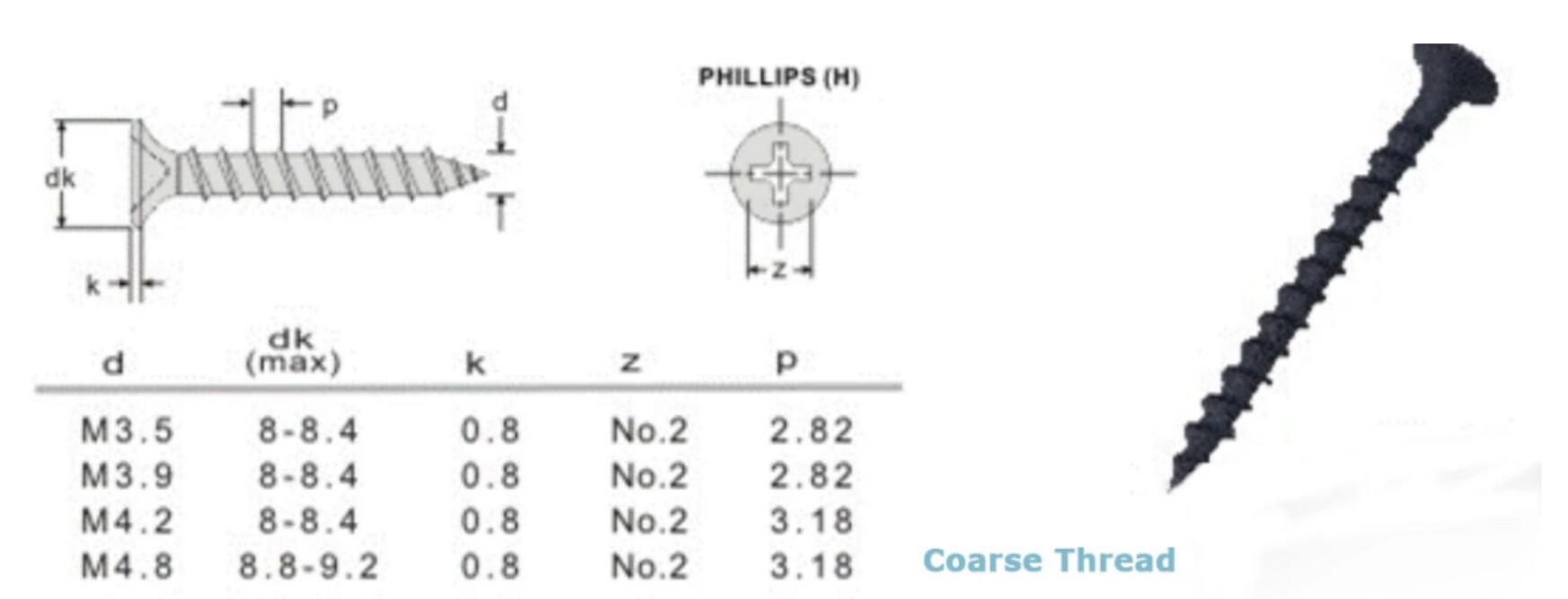

One important aspect of drywall screw selection is the type of screw head. The most popular styles are bugle head and flat head. Bugle head screws are designed to sink into the drywall without tearing the paper surface, which helps to maintain a smooth finish. Flat head screws, while effective, can sometimes create a bump if not installed correctly. For most applications, bugle head screws are recommended, especially when finishing the wall with paint or texture.

drywall screw length code companies

Using the correct length and type of drywall screw prevents common issues such as sagging, cracking, or even complete failure of the drywall installation. An adequately fastened drywall panel not only provides a seamless appearance but also ensures that it can withstand the stresses of everyday use. Incorrect screw lengths can lead to insufficient holding power, which may cause drywall to loosen over time, requiring costly repairs.

Companies that supply drywall screws often indicate the recommended lengths on their packaging, clearly labeling them for easy identification. Builders should always consult these guidelines, in addition to relevant building codes, when selecting screws for their projects. Moreover, using superior quality screws made from durable materials, such as hardened steel, is advisable. Such screws possess better shear strength and resistance to corrosion, leading to a more durable installation.

Understanding drywall screw length codes also plays a significant role in minimizing waste. By choosing the right size screws from the beginning, contractors can ensure that they do not over-purchase or under-purchase supplies, leading to a more efficient and cost-effective process.

In conclusion, the importance of understanding drywall screw length codes cannot be overstated. They are essential for maintaining the quality, durability, and safety of any drywall installation. Whether you are a professional contractor or a DIY enthusiast, having a clear grasp of which screws to choose will not only improve the outcome of your project but also enhance your confidence in taking on home improvement tasks. By following industry standards and selecting the appropriate screw lengths, you can ensure a flawless finish and create structures that stand the test of time.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024