Types and Applications of Self-Drilling Screws for Efficient Construction and Assembly

Understanding Self-Drilling Screw Types and Their Applications

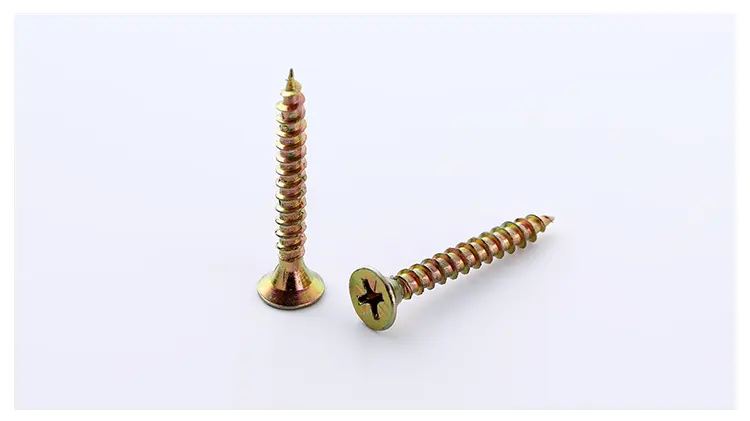

Self-drilling screws, often referred to as Tek screws, are fasteners designed to drill their own hole and thread the materials in which they are installed. This unique feature sets them apart from traditional screws that require pre-drilling. Self-drilling screws are particularly popular in metalworking, construction, and manufacturing due to their efficiency and reliability. This article delves into the types of self-drilling screws and their applications in various industries.

Types of Self-Drilling Screws

Self-drilling screws come in various types, each tailored for specific applications and materials

1. Type A - Metal to Metal Applications Type A screws are typically used for fastening thin metals. They have a sharp point that penetrates the material easily. These screws are ideal for applications like HVAC ductwork and exterior metal panels.

2. Type B - Metal to Wood Applications Designed for fastening metal to wood, Type B screws feature a drill point that allows for easy penetration into both materials. They are often used in building and construction where metal studs are fixed to wooden frames.

3. Type C - Heavy-Duty Applications Type C screws are heavier and longer, making them suitable for thicker materials and structural applications. They are commonly used in roofing applications where they secure metal sheets to steel or wood beams.

4. Type D - High Strength Steel These screws are designed with a larger head and a thick body, ensuring maximum torque and strength. They are used in applications where a high load-bearing capacity is required, such as in industrial settings.

self drilling screw types service

Benefits of Self-Drilling Screws

One of the significant advantages of self-drilling screws is their ability to streamline the assembly process. Traditional screws often necessitate multiple steps, including measuring, drilling, and fastening. In contrast, self-drilling screws reduce these steps to a single action, saving both time and labor costs.

Moreover, self-drilling screws provide a strong and secure connection between materials. This reliability is crucial in applications where structural integrity is paramount, such as in building frameworks and roofing systems. The design of the screws allows them to withstand various loads and stresses, making them suitable for high-performance environments.

Applications of Self-Drilling Screws

Self-drilling screws are widely used across various industries due to their versatility. Some notable applications include

- Construction Used for fastening roofing materials, wall panels, and structural components. - HVAC Essential for securing ductwork and ventilation systems. - Automotive Common in the assembly of cars and trucks, particularly in body and chassis applications. - Manufacturing Utilized in fabricating metal products, machinery, and equipment.

Conclusion

Self-drilling screws are a fundamental component across multiple industries, providing significant advantages in terms of speed, efficiency, and strength. Understanding the different types of self-drilling screws aids manufacturers and contractors in selecting the appropriate fastener for their specific applications. As technology advances and new materials emerge, self-drilling screws will continue to evolve, adapting to meet the changing needs of diverse sectors. Whether in construction, automotive, or manufacturing, these fasteners play a crucial role in modern engineering solutions.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024