Top Manufacturers of Truss Self-Drilling Screws for Construction Applications

The Rise of Truss Self-Drilling Screw Manufacturers

In the world of construction and woodworking, efficiency and reliability are key to success. Among the various fastening solutions, truss self-drilling screws have emerged as vital components in numerous applications, including roofing, steel framing, and furniture manufacturing. As the demand for these specialized fasteners continues to grow, so too does the landscape of manufacturers dedicated to producing them.

Understanding Truss Self-Drilling Screws

Truss self-drilling screws are a type of fastener designed specifically for metal-to-metal and metal-to-wood connections. They feature a unique head design that allows them to sit flush with the surface of the material, minimizing the risk of snags and damage. The self-drilling capability eliminates the need for pre-drilling, saving time and reducing labor costs on job sites. This feature is particularly beneficial in construction, where efficiency is paramount.

These screws come in various sizes and materials, including stainless steel, carbon steel, and coated options to resist corrosion. The diverse range allows manufacturers and builders to select the appropriate screw for each specific application, whether for outdoor projects subjected to harsh weather or indoor settings that require aesthetic considerations.

The Role of Manufacturers

As the demand for truss self-drilling screws increases, manufacturers are stepping up to meet the challenge. These companies are investing in advanced technologies and processes to enhance the quality and performance of their products. Modern manufacturing techniques include computer numerical control (CNC) machining, which allows for precision in the production of screws that meet stringent industry standards.

Additionally, many manufacturers are embracing sustainability in their operations. This involves utilizing eco-friendly materials, minimizing waste during production, and ensuring that their products can be recycled at the end of their life cycle. As builders and contractors become more environmentally conscious, having sustainable options is becoming a crucial selling point for manufacturers.

Market Trends and Innovations

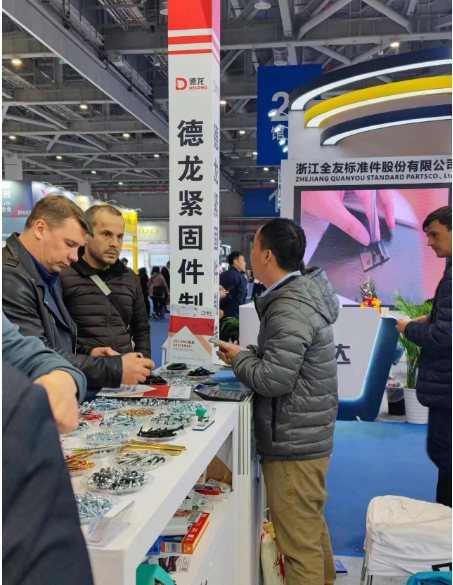

truss self drilling screw manufacturers

The market for truss self-drilling screws is experiencing several notable trends. One of the most significant is the growing use of technology in the manufacturing process. Automation is revolutionizing the industry, enabling manufacturers to produce large quantities of screws with consistent quality. Innovations such as robotic assembly lines and smart manufacturing systems are streamlining production methods and improving supply chain efficiency.

Moreover, with the advent of 3D printing technology, some manufacturers are exploring the potential to create custom-designed screws on demand. This capability allows builders to obtain specific fastener designs tailored to their projects, thereby enhancing efficiency and performance.

Another emerging trend is the integration of screws with smart technology. The incorporation of sensors within screws can provide builders with real-time information regarding installation quality and structural integrity, adding an extra layer of safety and reliability to construction projects.

Global Competition

The market for truss self-drilling screws is not limited to local manufacturers. Global competition has intensified as companies from different regions strive to capture market share. Manufacturers from Asia, Europe, and North America are all vying to provide high-quality products at competitive prices. This competition is driving innovation while also presenting challenges regarding compliance with international standards and regulations.

As companies expand their reach, they are also focusing on building strong relationships with their customers. This involves offering exceptional customer service, technical support, and after-sales services. By prioritizing customer satisfaction, manufacturers can foster loyalty and gain a competitive edge in the market.

Conclusion

The truss self-drilling screw industry is evolving rapidly, and manufacturers are at the forefront of this transformation. Through advancements in technology, sustainability efforts, and a focus on customer relationships, these companies are positioning themselves to meet the growing demands of the construction and woodworking sectors. As the industry continues to evolve, the role of manufacturers will remain crucial in providing reliable, efficient, and innovative fastening solutions that contribute to the success of projects around the world. With ongoing developments, the future of truss self-drilling screws looks promising, ensuring that builders have the tools they need for efficient construction and design.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024