Truss Head Self-Drilling Screw Manufacturers and Factories for Reliable Fastening Solutions

Truss Head Self-Drilling Screw Factories Leading Manufacturers in the Industry

In the world of construction and manufacturing, the need for reliable fasteners is paramount. Among the most effective solutions are truss head self-drilling screws, known for their versatility and efficiency. These screws come equipped with a unique head design and a drill point that eliminates the need for pre-drilling, making them an essential component in various building applications. This article explores the role of factories manufacturing these specific screws, highlighting their production processes, benefits, and the importance of selecting reputable manufacturers.

Understanding Truss Head Self-Drilling Screws

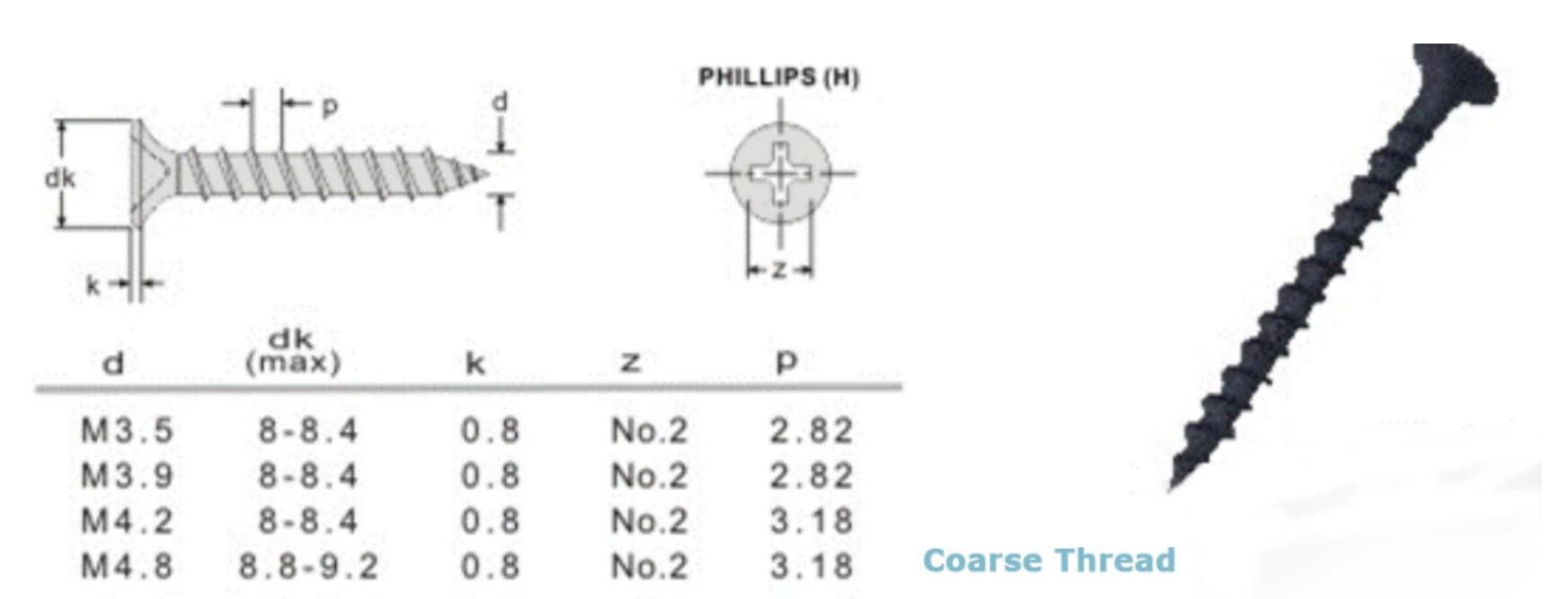

Truss head self-drilling screws are characterized by their broad, flat heads, which provide a strong bearing surface. This design allows them to distribute the load evenly, making them ideal for use in environments where strength is critical. The self-drilling feature, or drill point, allows these screws to bore into materials like metal or wood directly, simplifying assembly and enhancing productivity.

These screws find extensive applications in the construction of metal roofs, siding, and wooden structures. Their efficiency caters to both industrial and residential projects, making them a staple in the toolkit of builders and contractors.

The Manufacturing Process

The production of truss head self-drilling screws involves several key stages, emphasizing precision and quality control. The process typically begins with the procurement of raw materials, which are usually high-quality steel or stainless steel. These materials are selected based on their tensile strength and resistance to corrosion, crucial factors that determine the longevity and performance of the screws.

Once the materials are sourced, they undergo a series of treatments, such as cold forging, which enhances their durability and structural integrity. The cold forging process shapes the screw blank, after which a specialized machine is used to form the truss head. This process requires advanced technology to ensure that each screw meets stringent design specifications.

The next phase involves the creation of the self-drilling tip, a critical component that allows the screw to penetrate materials without additional drilling. The manufacturing factory employs CNC (Computer Numerical Control) machining and other automated systems to ensure precision in the production of these drill points.

truss head self drilling screw factories manufacturer

Quality Control Measures

A reliable manufacturer of truss head self-drilling screws will implement stringent quality control measures throughout the production process. This includes regular inspections and testing of raw materials, in-process checks, and final product evaluations. Quality assurance teams will assess factors such as tensile strength, corrosion resistance, and overall dimensions to ensure that every batch meets industry standards.

Factories often comply with ISO standards, which demonstrate their commitment to quality and adherence to international best practices. Certifications can significantly influence the reputation of a manufacturer, making it vital for customers to select suppliers with recognized quality credentials.

The Importance of Choosing Reputable Manufacturers

With many options available in the market, selecting a reputable manufacturer for truss head self-drilling screws is crucial. A well-established factory often has a proven track record, ensuring that customers receive high-quality products that meet their specific needs.

Moreover, reputable manufacturers typically offer a variety of screw sizes, materials, and finishes, allowing clients to choose the best option for their projects. They also provide detailed product specifications and expert advice, which can help contractors make informed decisions about their fastener needs.

In addition, a reliable supplier will have a robust customer service function, essential for addressing queries, processing orders, and handling any issues that may arise post-purchase. A manufacturer that stands behind its products with warranties or guarantees further solidifies its commitment to quality and customer satisfaction.

Conclusion

In conclusion, truss head self-drilling screws play a vital role in modern construction, providing durability and ease of use. Factories that specialize in manufacturing these screws invest in high-quality materials, advanced technology, and rigorous quality control to deliver exceptional products. By partnering with reputable manufacturers, builders and contractors can ensure that their projects not only meet but exceed safety and durability standards, contributing to the overall success of their construction endeavors. As the industry continues to evolve, the demand for such reliable fasteners will undoubtedly grow, further emphasizing the importance of quality manufacturing in the sector.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024