Top Suppliers for No 4 Self Tapping Screws Available in the Market Today

The Importance of Selecting the Right Supplier for No. 4 Self-Tapping Screws

When it comes to construction and manufacturing, the significance of the right hardware cannot be overstated. Among the essential fasteners, self-tapping screws play a vital role in ensuring the integrity and longevity of structures, products, and various applications. Specifically, the No. 4 self-tapping screw is popular across industries for its versatility and reliability. However, sourcing these screws from a reputable supplier is crucial for optimal performance.

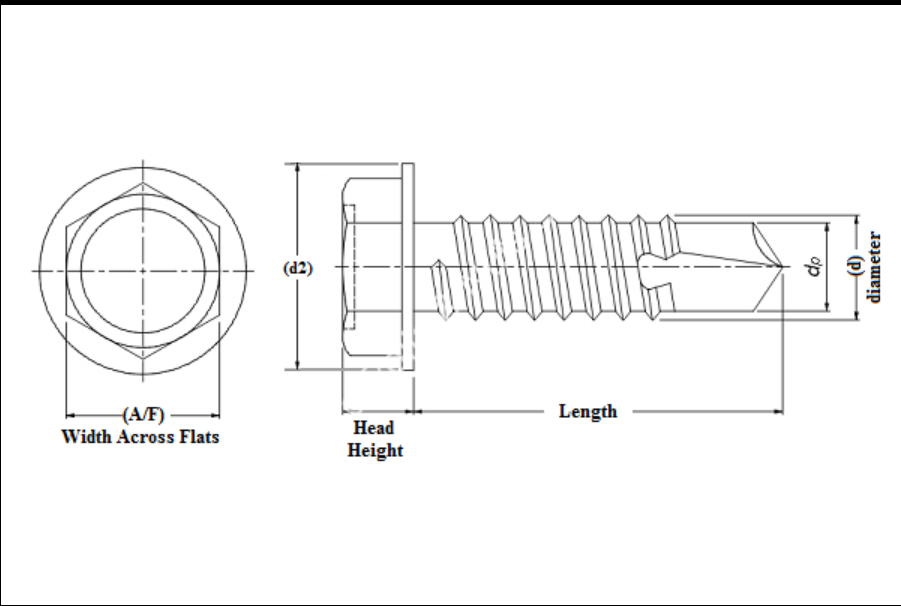

Understanding No. 4 Self-Tapping Screws

No. 4 self-tapping screws, measuring approximately 0.112 inches in diameter, are often used in applications requiring a lower load-bearing capacity, such as in lightweight materials or thin sheets. They are designed to create their own thread as they are driven into a material, eliminating the need for pre-drilled holes in many cases. This makes them particularly efficient in saving time and labor costs in assembly processes. However, the performance of these screws heavily depends on their material quality and design, which is why choosing the right supplier is critical.

Quality Assurance and Material Selection

The material composition of self-tapping screws can significantly influence their durability, corrosion resistance, and overall performance. High-quality suppliers typically offer screws made from materials such as stainless steel, carbon steel, or specialized alloys, which provide additional features like rust resistance. Therefore, it’s essential to select a supplier that adheres to stringent quality standards and offers products certified by relevant industry bodies. A reliable supplier will provide detailed specifications and certifications, ensuring that you receive screws that meet and exceed expectations.

Customization Options

no 4 self tapping screw supplier

Every manufacturing and construction project is unique, which may require specific dimensions, threads, or coatings. A good supplier will offer customization options, allowing you to choose the right head styles, drive types, and surface finishes tailored to your needs. This level of flexibility ensures that you can achieve the best results in your application, enhancing both efficiency and effectiveness.

Supply Chain Reliability

Dependability in the supply chain is another crucial factor when selecting a No. 4 self-tapping screw supplier. Timely deliveries and consistent stock availability can impact project timelines significantly. The last thing any manufacturer or contractor wants is to experience downtime due to inaccessible fasteners. An established supplier will have a proven track record of reliable logistics and inventory management, ensuring that you have access to the necessary materials when you need them.

Technical Support and Expertise

A supplier with robust technical support can be an invaluable asset. This includes offering guidance on the best screws for specific applications, installation tips, and recommendations based on experiences from other clients. Suppliers who understand the nuances of self-tapping screw applications can help you make informed decisions that enhance the performance of your projects.

Conclusion

In conclusion, sourcing No. 4 self-tapping screws from a reliable supplier is essential for ensuring the structural integrity and efficiency of your projects. Quality assurance, material selection, customization options, supply chain reliability, and technical support all contribute to a successful partnership with your supplier. By investing time in finding the right source for your self-tapping screws, you can enhance productivity, minimize errors, and ultimately, ensure the success of your manufacturing or construction endeavors. Remember, the right screw may be small, but its impact on your project's success can be significant.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024