Top Suppliers for Countersunk Head Self-Tapping Screws at Competitive Prices and Quality

The Importance of Self-Tapping Screw Countersunk Heads A Focus on Quality Suppliers

In the world of fasteners, self-tapping screws, particularly those with countersunk heads, hold a significant place due to their unique design and functional advantages. These screws are widely used in various industries, ranging from construction to electronics, providing secure and efficient fastening solutions. The importance of selecting a reliable supplier for self-tapping screws with countersunk heads cannot be overstated, as it directly impacts product quality, operational efficiency, and ultimately, customer satisfaction.

Understanding Self-Tapping Screws and Countersunk Heads

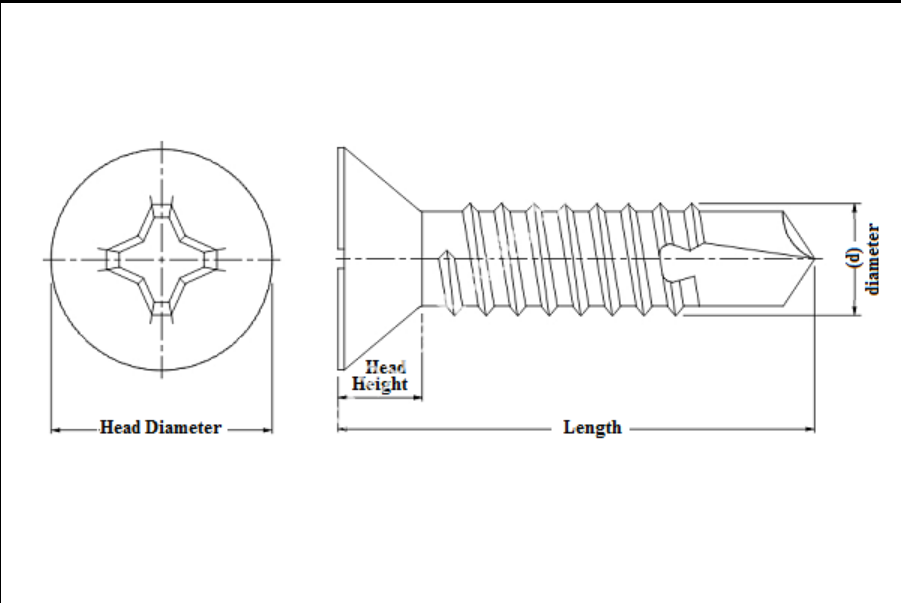

Self-tapping screws are designed to create their own thread as they are driven into materials, which can be metals, plastics, or wood. This feature eliminates the need for pre-drilling holes, saving time and labor costs. The countersunk head plays a crucial role in the aesthetic and functional aspects of the screw. A countersunk head allows the screw to sit flush with the surface of the material, providing a sleek appearance while also reducing the risk of snagging or injury.

The Role of Quality Suppliers

When it comes to sourcing self-tapping screws with countersunk heads, the choice of supplier significantly affects the overall performance and reliability of the final product. Here are several key aspects to consider when evaluating suppliers

1. Material Quality The durability of self-tapping screws largely depends on the materials used in their manufacture. High-quality suppliers often utilize premium materials, such as stainless steel or hardened carbon steel, which can withstand various environmental conditions and prevent corrosion. This is particularly important for screws used in outdoor applications or in moist environments.

self tapping screw countersunk head supplier

2. Manufacturing Standards Established suppliers adhere to stringent manufacturing standards and quality control processes. Look for suppliers who comply with international standards, such as ISO and ASTM. These certifications not only ensure the quality of the screws but also provide assurance that the products meet specific performance criteria.

3. Variety and Customization A reputable supplier should offer a wide range of self-tapping screws with various sizes, coatings, and head styles, including countersunk options. Some projects may require custom specifications, and suppliers who can accommodate unique needs stand out in the market.

4. Technical Expertise Suppliers with substantial industry experience often have a deeper understanding of the products they offer. Their expertise can be invaluable in helping clients select the right screws for specific applications, thereby enhancing performance and safety.

5. Customer Service Quality suppliers prioritize their customers by providing excellent support and service. They should be willing to assist with inquiries, provide technical documentation, and ensure timely delivery. A responsive supplier establishes a good working relationship, which is essential for long-term partnerships.

The Conclusion

In conclusion, the selection of an appropriate supplier for self-tapping screws with countersunk heads is a critical decision in any project involving fastening solutions. As the demand for these screws continues to grow across industries due to their practicality and aesthetic appeal, aligning with a quality supplier can make a significant difference. By emphasizing material quality, manufacturing standards, product variety, technical expertise, and customer service, businesses can ensure they are equipped with reliable fasteners that meet their needs. Investing time in identifying and establishing a relationship with a trusted supplier can lead to enhanced operational efficiency and increased customer satisfaction, paving the way for future success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024