Top Recommendations for Self Tapping Screws with Optimal Diameter for Your Projects in 2010

Understanding the Best 10 Self-Tapping Screw Diameters A Comprehensive Guide

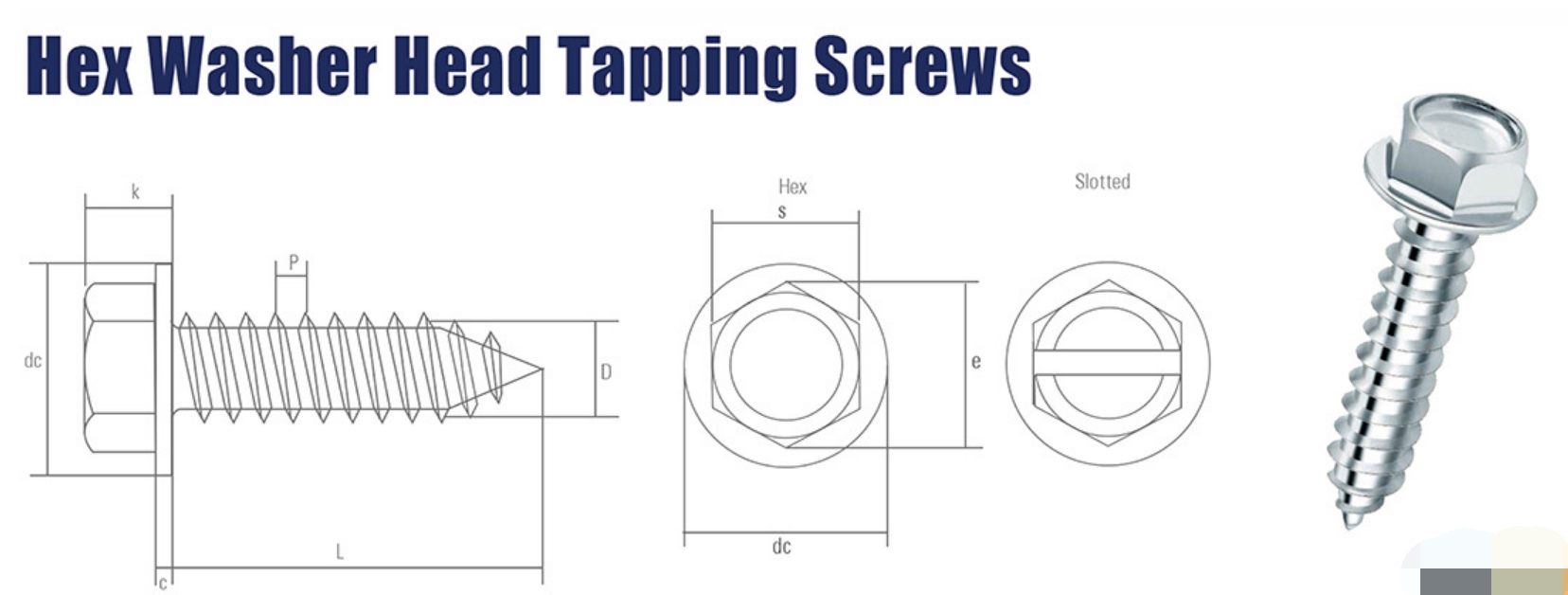

Self-tapping screws play an essential role in numerous construction, manufacturing, and DIY projects. Their ability to create their own threads in various materials, such as metal and wood, makes them an indispensable tool. However, choosing the right diameter for self-tapping screws is crucial for ensuring optimal performance and durability. This article will explore the best ten self-tapping screw diameters, discussing their applications, benefits, and considerations.

1. The Basics of Self-Tapping Screws

Self-tapping screws are designed to tap their own holes as they are driven into the material. This feature eliminates the need for pre-drilling, saving time and labor. Made from various materials, including steel, stainless steel, and brass, self-tapping screws come in different lengths and diameters, each suited for specific applications.

2. Understanding Diameter Measurements

The diameter of a self-tapping screw is typically measured in inches or millimeters. Selecting the appropriate diameter is vital because it affects the screw's holding power and the integrity of the material being fastened. A screw that is too small may not provide sufficient grip, while one that is too large may cause the material to crack or fail.

3. Common Self-Tapping Screw Diameters

Here are ten popular self-tapping screw diameters, their applications, and benefits

1. 4 (2.8 mm) This small diameter is ideal for light-duty applications, such as securing thin plastics and lightweight metal components.

2. 6 (3.5 mm) Commonly used in household items, 6 screws are perfect for fastening hardware and thin sheet metals.

best 10 self tapping screw diameter

4. 10 (4.8 mm) Ideal for heavier applications, such as attaching larger fixtures or panels, the 10 diameter offers increased holding power.

5. 12 (5.5 mm) This diameter is well-suited for heavy-duty installations, including framing and construction work, where robust holding strength is necessary.

6. 14 (6.3 mm) The 14 screw is often used in metal fabrication and structural applications, where significant load-bearing capacity is required.

7. 16 (7.1 mm) Preferred for anchoring larger objects or materials, 16 screws provide excellent grip and durability.

8. 18 (7.9 mm) Frequently used in commercial projects, this diameter offers strong holding power in both wood and metal applications.

9. 20 (8.7 mm) This size is suitable for high-stress environments and is often used in construction and industrial applications.

10. 24 (10 mm) The largest commonly used self-tapping screw, 24 is perfect for high-load requirements, such as securing heavy machinery or structural elements.

4. Selecting the Right Diameter

When choosing the right diameter for self-tapping screws, consider several factors the type of material you'll be fastening, the load it will bear, and specific environmental conditions (such as humidity or exposure to chemicals). Always refer to manufacturer guidelines and relevant building codes to ensure compliance and safety.

Conclusion

Selecting the right diameter of self-tapping screws is vital for achieving successful outcomes in various applications. Understanding the specifications and applications of each diameter helps ensure that you choose the best fit for your project needs. With a solid grasp of the best 10 self-tapping screw diameters, you can confidently tackle your next construction or DIY project, ensuring both strength and durability in your fastenings.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024