threaded flat washer supplier

The Importance of Choosing a Reliable Threaded Flat Washer Supplier

In the realm of manufacturing and construction, the choice of fasteners is paramount. Among the multi-faceted array of fasteners, threaded flat washers play a crucial role in ensuring structural integrity and reliability. A threaded flat washer is a circular disc with a hole in the center, which is used to distribute the load of a threaded fastener, such as a screw or bolt. This article explores the significance of selecting a reputable threaded flat washer supplier and the factors to consider when making this pivotal decision.

Understanding Threaded Flat Washers

Threaded flat washers serve various functions, including load distribution, prevention of bolt loosening, and prevention of material damage. They ensure that the force exerted by the fastener is evenly distributed over the assembly. This is particularly important in applications where vibrations and dynamic loads are common, as it helps maintain the integrity of the joint.

The Role of a Supplier

A reliable supplier of threaded flat washers can significantly influence the quality and performance of the end product. When sourcing washers, manufacturers must consider several crucial factors

1. Quality Assurance The primary consideration when choosing a threaded flat washer supplier is the quality of their products. High-quality washers are often made from durable materials such as stainless steel, carbon steel, or other corrosion-resistant alloys. These materials ensure that the washers can withstand various environmental factors, including moisture and temperature fluctuations, which can lead to rust and mechanical failure.

threaded flat washer supplier

2. Standards Compliance It is essential to verify that the supplier adheres to industry standards such as ISO or ASTM. Compliance with these standards not only guarantees the quality of the washers but also ensures that they are tested for performance under various conditions. This can provide peace of mind for manufacturers, knowing that they are using products that meet rigorous safety and quality benchmarks.

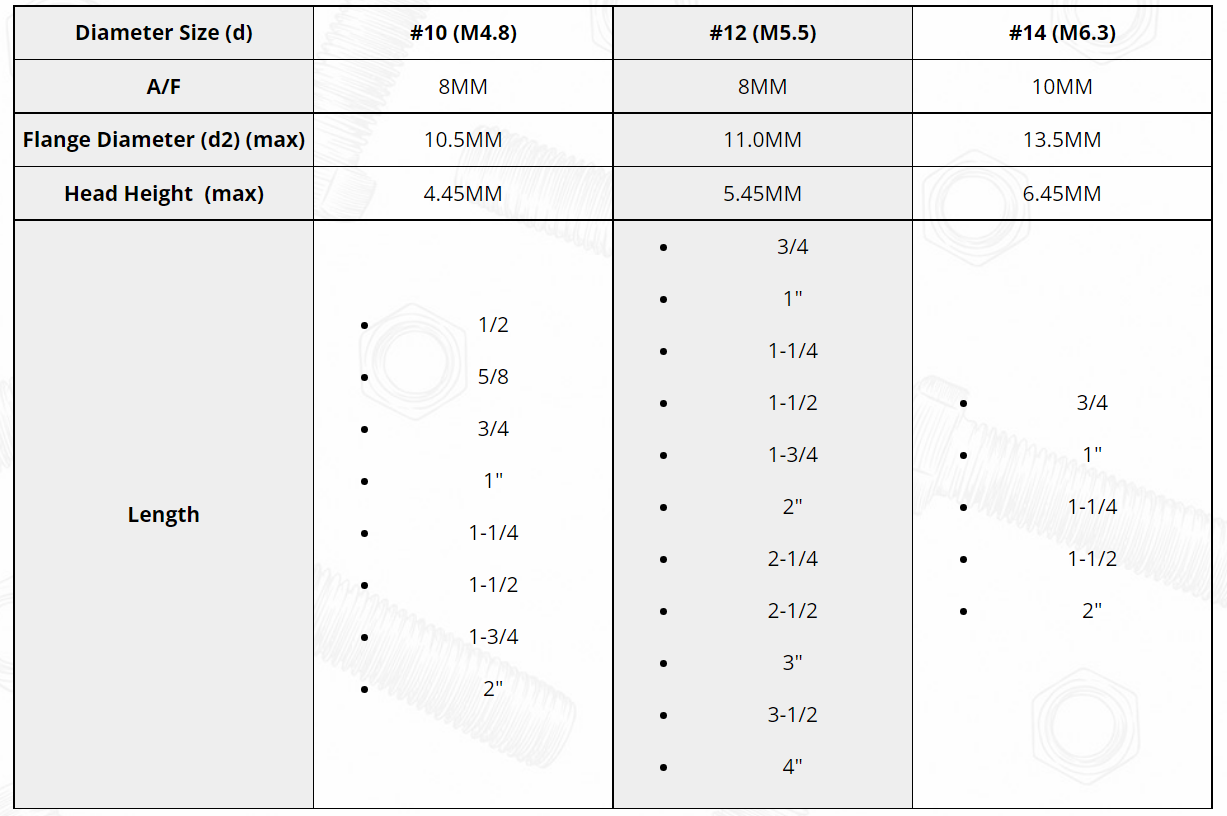

3. Variety of Offerings A supplier that offers a wide range of washers—varying in size, thickness, and materials—can provide a competitive advantage to manufacturers. This versatility allows businesses to find the exact specifications they need for different projects without having to engage with multiple vendors.

4. Customization Some projects may require customized threaded flat washers based on specific needs. A supplier that is willing to offer tailored solutions can be particularly beneficial. Customization options such as different coatings for added protection or unique sizes can ensure a perfect fit for specialized applications.

5. Customer Service and Support Excellent customer service can significantly enhance the purchasing experience. Suppliers that provide knowledgeable support can assist clients in making informed decisions regarding their product choices, helping to ensure that manufacturers receive washers that are perfectly suited to their applications.

6. Pricing and Terms While price shouldn't be the only consideration, it is still important to find a supplier that offers competitive pricing without compromising quality. Additionally, examining the terms of sale, including discounts for bulk orders and return policies, can also be advantageous.

Conclusion

In summary, choosing the right threaded flat washer supplier is more than just a purchasing decision; it is an investment in quality and reliability. By focusing on quality assurance, compliance with standards, product variety, customization options, and customer support, manufacturers can make informed choices that lead to successful outcomes in their projects. A trustworthy supplier will not only provide quality washers but also establish a long-term partnership that aids in achieving operational excellence.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024