The Impact of Chinese Drywall on the Use of Drywall Screws in Construction Projects

The Essential Guide to Selecting China Drywall and Drywall Screws

When it comes to construction and interior design, drywall has become a staple material, valued for its versatility and ease of installation. Particularly, China-produced drywall has gained popularity due to its affordability and availability. However, selecting the right drywall and accompanying materials, such as drywall screws, is critical for the stability and longevity of the finished project.

Understanding Drywall

Drywall, also known as gypsum board or plasterboard, consists of a core made of gypsum pressed between two sheets of heavy paper. It is commonly used to create interior walls and ceilings. The demand for drywall has soared due to its qualities, which include fire resistance, sound insulation, and an ability to be shaped or cut to fit various architectural designs. China has emerged as a leading manufacturer of drywall, providing options that cater to a wide range of building needs.

One of the primary benefits of choosing China drywall is its cost-effectiveness. The production processes in China allow for lower prices while maintaining acceptable quality standards. However, buyers must be vigilant and ensure that the drywall they select meets necessary safety and durability standards. It is advisable to check certifications, such as ASTM (American Society for Testing and Materials) compliance or other relevant quality assurance marks, to avoid potential issues in the future.

Choosing the Right Drywall Screws

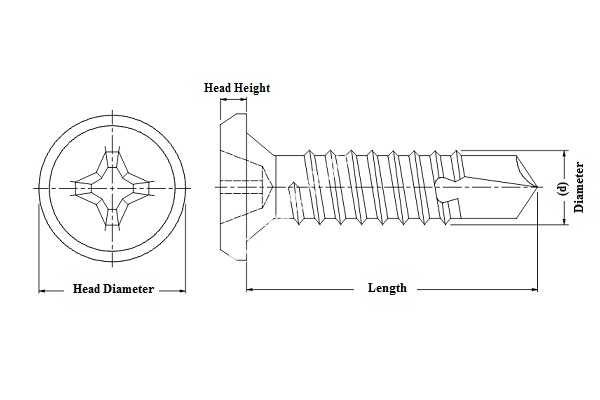

Equally essential as the drywall itself are the screws used for installation. Drywall screws are specifically designed to secure drywall sheets to wooden or metal studs. They come in various sizes, types, and coatings. The most common types are coarse-thread screws, which are suited for wood, and fine-thread screws for metal studs.

When selecting drywall screws, consider the following factors

china drywall to drywall screw

1. Material Most drywall screws are made of steel with a coating to prevent rusting. For environments with high moisture, consider using corrosion-resistant screws, such as those with a galvanized or zinc coating, to enhance durability.

2. Length and Diameter The length of the screw should match the thickness of the drywall and the stud material. General guidelines suggest using 1 1/4 inch screws for 1/2 inch drywall and longer screws for thicker boards. The diameter is also essential; standard screws usually have a 6 or 8 gauge, ensuring a sturdy hold.

3. Head Style Drywall screws come with different head styles, including bugle head, which helps accommodate the drywall surface and minimizes the risk of tearing. This type is popular for its flush finish, making it easier to conceal seams during the taping and finishing process.

4. Type of Duty There are heavy-duty screws available for specific applications, such as hanging heavy items on drywall. Assess the needs of your project to determine whether you need regular screws or heavy-duty options.

Installation Tips

Once you have selected the appropriate drywall and screws, it's crucial to follow best practices during installation. Pre-drilling may be unnecessary but can help prevent splitting in wooden studs. Drive screws just below the surface of the drywall, but be careful not to break the paper surface. This ensures the screws will hold securely and allows for a smoother finish when taping.

Conclusion

Choosing the right China drywall and drywall screws is vital for successful drywall installation. Quality materials lead to a durable finish that can withstand the test of time. By paying careful attention to the specifications and types of drywall and screws, both DIY enthusiasts and professional contractors can ensure their projects are not only aesthetically pleasing but also structurally sound. With the right choices, your drywall installations can enhance the beauty and functionality of any space.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024