supply hex washer head self drilling screw exporters product

The Growing Market for Supply of Hex Washer Head Self-Drilling Screws A Comprehensive Insight

In the realm of construction and manufacturing, the demand for effective fastening solutions has seen a significant surge. Among the myriad of fasteners available, hex washer head self-drilling screws have emerged as a crucial component for various applications. This article delves into the characteristics, applications, and market trends associated with these screws, specifically focusing on exporters in this sector.

Understanding Hex Washer Head Self-Drilling Screws

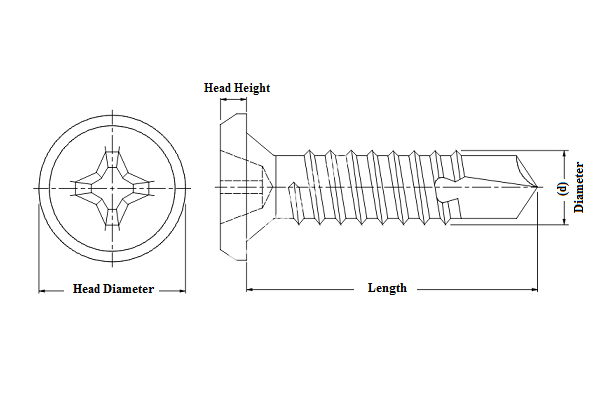

Hex washer head self-drilling screws are designed to penetrate a variety of materials without the need for pre-drilling holes, thanks to their unique drill point design. The hex washer head allows for a better grip and offers a larger bearing surface, which distributes the load more evenly compared to round or flat heads. This design feature not only enhances the performance during installation but also ensures a more secure fastening in the long run.

These screws are typically made from high-quality materials, such as stainless steel, carbon steel, or even brass, providing strength and resistance against corrosion. They come in various sizes and coatings—like zinc-plated or black oxide—to meet different environmental and aesthetic requirements.

Applications in Diverse Industries

The versatility of hex washer head self-drilling screws allows for their application across various sectors, including construction, automotive, and manufacturing. In the construction industry, these screws are widely used for metal roofing and siding installations, where the ability to self-drill into metal ensures faster assembly and minimizes labor costs. Their use extends to wood and concrete as well, showcasing their adaptability.

In the automotive industry, these screws are utilized in assembling parts where a permanent fastening solution is required

. The manufacturing sector benefits from their rapid installation capabilities, making them ideal for assembly lines where efficiency is paramount.The Export Market Dynamics

supply hex washer head self drilling screw exporters product

As the global demand for durable and efficient fastening solutions continues to rise, the export market for hex washer head self-drilling screws has become increasingly competitive. Countries with robust manufacturing capabilities, such as China, Germany, and the United States, dominate the supply chain, catering to international markets.

Exporters play a crucial role in meeting the needs of various industries abroad. They provide not just the product itself but also essential services such as custom manufacturing and logistics support. This level of service helps businesses in other countries to maintain their production schedules without interruption, making these exporters valuable partners in the supply chain.

Trends in the Global Market

Several key trends have emerged in the market for hex washer head self-drilling screws. One prominent trend is the growing emphasis on sustainability. Many manufacturers are exploring eco-friendly materials and processes to minimize environmental impact. Eco-conscious consumers are pushing companies to adopt greener practices, which influences how screws are manufactured and packaged.

Moreover, advancements in technology have led to the development of enhanced screw designs that offer superior performance. Innovations such as better corrosion resistance and improved drill points make these screws even more appealing to industries looking for reliability and longevity in their fastening solutions.

Another trend is the increasing customization of screws to meet specific application needs. Exporters are often required to provide tailored solutions, reflecting the diverse needs of customers across different regions. This need for customization has prompted many exporters to invest in advanced manufacturing technologies that allow for flexibility and rapid prototyping.

Conclusion

The market for hex washer head self-drilling screws is poised for continued growth, driven by the demands of various industries for reliable and efficient fastening solutions. Exporters of these products play an essential role in the global supply chain, supporting manufacturers and builders worldwide. As trends in sustainability and customization continue to shape the industry, those involved in the export of hex washer head self-drilling screws must remain agile and responsive to changing market conditions. In this dynamic environment, the ability to innovate and adapt will be key to maintaining competitive advantage and ensuring long-term success in this vital sector of the market.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024