Suppliers of Spring Washer Bolts for Various Industrial Applications and High-Quality Standards

The Importance of Spring Washer Bolts in Modern Engineering

In the realm of engineering and manufacturing, fasteners play a crucial role in ensuring the integrity and reliability of various structures and components. Among these fasteners, spring washer bolts stand out as vital components that provide essential benefits in numerous applications. This article explores the significance of spring washer bolts, their suppliers, and their applications in various industries.

What is a Spring Washer Bolt?

A spring washer bolt combines a standard bolt with a spring washer to enhance fastening efficacy. The spring washer, typically made of resilient materials like carbon steel or stainless steel, is designed to absorb and dissipate energy. This characteristic is particularly important in applications subject to vibration, thermal expansion, or dynamic loads, where traditional bolts may loosen over time. The spring washer provides a spring effect, maintaining tension and allowing the bolt to resist loosening, thereby ensuring a secure connection.

Why Spring Washer Bolts are Essential

1. Enhanced Vibration Resistance One of the primary reasons for using spring washer bolts is their ability to withstand vibrations. In applications such as automotive, aerospace, and heavy machinery, components are frequently subjected to vibrations that can cause standard bolts to loosen. The spring washer compensates for these vibrations, keeping connections tight.

2. Dynamic Load Management Structures and machines often experience dynamic loads due to movement or changes in weight. Spring washer bolts help maintain stability under these conditions, ensuring that the integrity of the assembly remains intact over time.

3. Thermal Expansion Compensation Materials expand and contract with temperature fluctuations. The flexible nature of spring washers enables them to manage this expansion and contraction, keeping the bolts secure and preventing loosening that can occur due to temperature changes.

4. Easy Installation and Maintenance The design of spring washer bolts allows for quick installation. They are also easy to inspect and replace, which is a crucial factor in maintenance-heavy industries like construction and manufacturing.

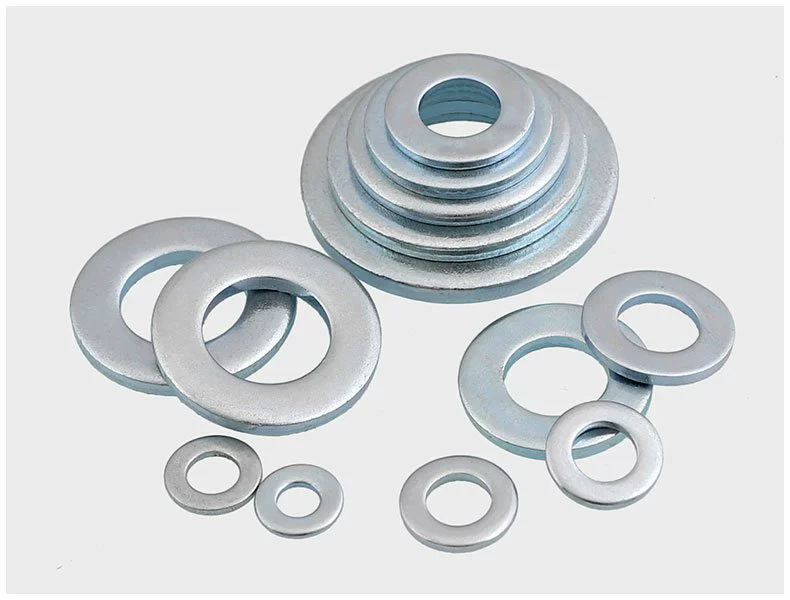

spring washer bolt16 suppliers

Suppliers of Spring Washer Bolts

With the growing demand for spring washer bolts across various sectors, numerous suppliers have emerged to provide these essential components. When selecting a supplier, it's crucial to consider factors such as quality, variety, and customer support.

1. Quality Assurance Reputable suppliers should adhere to strict quality standards, providing certified materials that meet industry-specific requirements. Certifications such as ISO 9001 can indicate a supplier's commitment to quality.

2. Variety of Options Different applications may require specific types of spring washer bolts, including varying sizes, materials, and finishes. A good supplier will offer a diverse range of options to meet different engineering needs.

3. Expertise and Support Suppliers with extensive industry experience can provide valuable insights into which products are best suited for particular applications. They should also offer technical support to assist customers in making informed decisions.

4. Supply Chain Efficiency Timely delivery and a reliable supply chain are critical factors for companies relying on spring washer bolts. Suppliers who can demonstrate efficient logistics and prompt service are preferable partners.

Conclusion

Spring washer bolts are indispensable in modern engineering and manufacturing sectors due to their unique benefits in enhancing vibration resistance, managing dynamic loads, and compensating for thermal expansion. With many suppliers providing a range of options, it's essential for businesses to select partners that prioritize quality, variety, and customer support. By leveraging the advantages of spring washer bolts, companies can significantly improve the durability and reliability of their products and structures, ultimately leading to better performance and safety in their operations.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024