standard length drywall screw products

Understanding Standard Length Drywall Screw Products

When it comes to constructing and finishing walls, drywall is a go-to material for professionals and DIY enthusiasts alike. However, the success of drywall installation does not solely rely on the quality of the panels themselves but also significantly on the fasteners used. Among these, standard length drywall screws play a crucial role, ensuring that the panels are firmly secured, preventing sagging and potential damage over time. This article will explore standard length drywall screws, their specifications, types, and best practices for use.

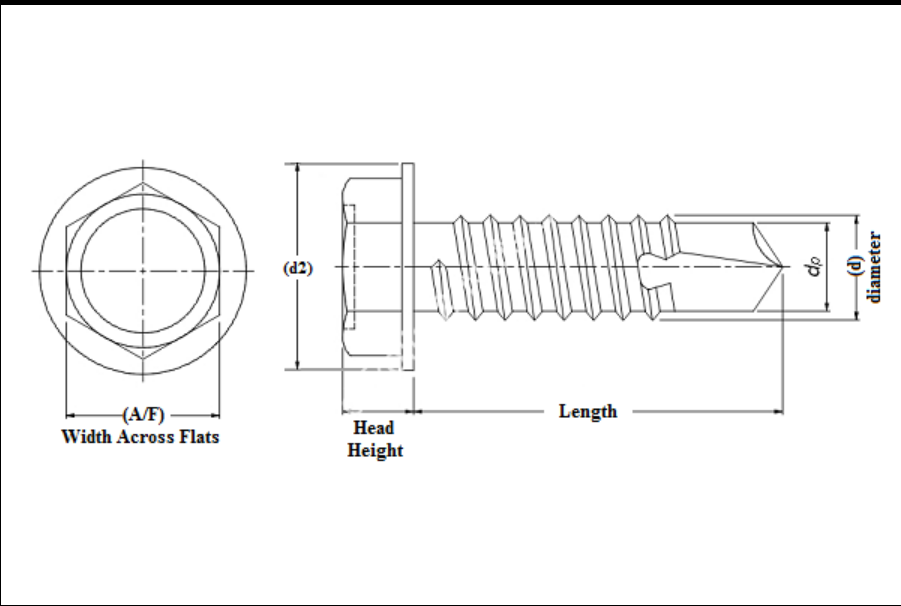

Drywall screws are specifically designed for attaching drywall to wood or metal studs. Unlike regular screws, drywall screws have a sharp point that allows them to penetrate drywall and reach the underlying framing material quickly. The head of a drywall screw is also uniquely designed; it’s typically flat and sharp, which helps sink into the drywall without tearing the paper face. This is essential for creating a smooth finish and allowing the joint compound to adhere properly.

Standard Lengths and Types

Standard length drywall screws come in various sizes, with the most common lengths ranging from 1 inch to 3 inches. The length of the screw you choose depends on the thickness of the drywall and the material of the framing behind it. For example, a standard 1.25-inch screw is often used for attaching 1/2-inch drywall to wood studs, whereas a longer 1.5-inch screw may be necessary for thicker panels or when working with metal studs.

There are primarily two types of standard length drywall screws coarse thread and fine thread. Coarse thread screws are ideal for wood framing as they provide better grip in softer materials. Fine thread screws are more suitable for metal studs, as they can easily penetrate thin metal without stripping. Furthermore, drywall screws are often coated with a corrosive-resistant finish, enhancing their longevity and durability, particularly in high-humidity environments.

Best Practices for Using Drywall Screws

When installing drywall, using the correct technique with drywall screws is essential to ensure a secure and professional finish. Here are some best practices to keep in mind

standard length drywall screw products

1. Spacing Maintain proper spacing between screws to ensure a tight fit. Typically, screws should be placed every 12 to 16 inches along the studs, and about 8 to 12 inches apart in the field (the middle area) of the drywall sheet.

2. Depth Screws should be installed slightly below the surface of the drywall paper without breaking through it. This allows for the joint compound to cover the screw head seamlessly, giving a smooth surface for finishing.

3. Avoid Overdriving Overdriving screws can lead to damage to the drywall and can weaken the hold. Use a drywall screw gun or a power drill with a clutch setting for optimal results.

4. Pre-drilling for Metal When working with metal studs, pre-drilling pilot holes can make the job easier and reduce the chances of stripping the screws.

5. Adhesive Use In addition to screws, using a construction adhesive can provide extra support, particularly in high-stress areas.

Conclusion

Standard length drywall screws are an indispensable component of effective drywall installation. By understanding their specifications, correct usage, and the variety of available options, contractors and DIYers can achieve professional results in their drywall projects. Proper selection and installation of these screws not only ensure the durability of the drywall but also contribute to a smooth and aesthetically pleasing finish, making them an essential tool in any construction toolkit. Whether you are a seasoned professional or a weekend warrior, understanding the ins and outs of drywall screws will elevate the quality of your work and pave the way for successful building projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024