spring washer definition factories

Understanding Spring Washers Definition and Applications in Manufacturing

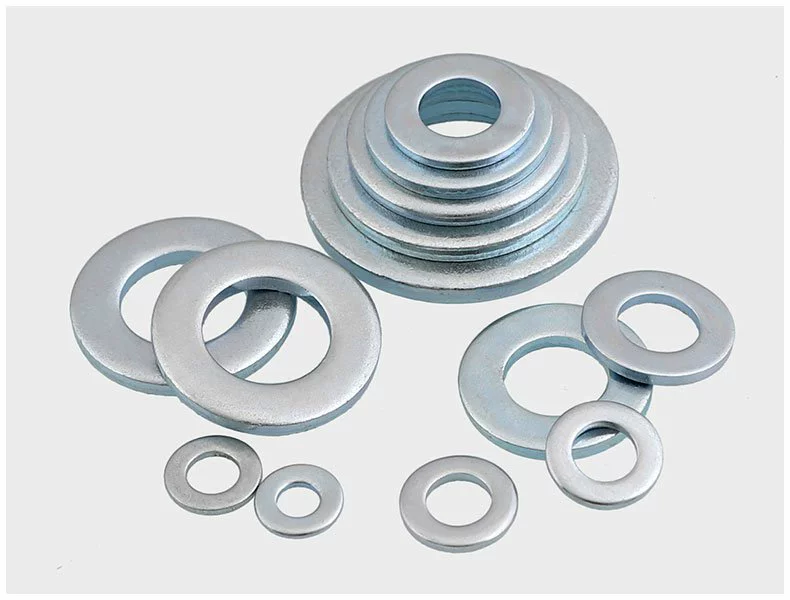

Spring washers are a crucial component in various mechanical applications, designed to provide flexibility and support under load. These washers are engineered with a specific shape to maintain tension and resist relaxation, making them indispensable in numerous industries, including automotive, aerospace, and electronics. This article delves into the definition of spring washers, their manufacturing process, and their varied applications.

Definition of Spring Washers

Spring washers are thin, curved metal disks that exert a force upon compression. Their primary function is to absorb shock, maintain tension, and prevent loosening of bolted joints. Unlike standard flat washers, spring washers have a unique design that allows them to exert a spring-like force. This feature is essential in applications where vibration, shock, or repetitive motion might cause fasteners to loosen over time.

One of the most common types of spring washers is the Belleville washer, which has a conical shape. This type is especially popular due to its ability to manage large loads in a compact space. Other variations include wave washers and lock washers, each offering specific advantages based on their design and use case.

Manufacturing Process of Spring Washers

The production of spring washers involves several steps, typically including material selection, forming, heat treatment, and finishing. High-quality materials such as stainless steel, carbon steel, or alloy steel are chosen for their strength and elastic properties. The material is then cut into the desired shape using precision tools.

The forming process is critical, as it determines the specific curvature and dimensions of the washer. This can be accomplished through methods like stamping or bending. After forming, heat treatment is applied to enhance the mechanical properties of the washer, such as yield strength and hardness. This step ensures that the washer can withstand significant loads and resist deformation.

spring washer definition factories

Finally, finishing processes, including cleaning, coating, or plating, are implemented to improve the washers’ durability and resistance to corrosion. The entire manufacturing system must align with stringent quality control measures to ensure that each washer meets industry standards.

Applications of Spring Washers

Spring washers find extensive use across multiple sectors. In the automotive industry, they are employed to secure engine components and suspension systems, where they help to maintain consistent pressure and prevent loosening during operation. Their ability to absorb shock is vital in reducing wear and tear on critical components, thereby enhancing vehicle longevity and performance.

In aerospace applications, where safety is paramount, spring washers are used in various assemblies to ensure the integrity of fastened joints under the unique stresses experienced during flight. The lightweight nature of spring washers, coupled with their strength, makes them ideal for use in aircraft manufacturing.

Electronics is another field where spring washers play a crucial role. They are utilized in mounting electrical components, ensuring that connections remain secure even in the presence of vibrations or thermal expansion. This application is particularly important in devices that experience frequent movement or temperature changes.

Furthermore, spring washers are beneficial in machinery and heavy equipment, where they help prevent the loosening of bolts and other fasteners under vibration. This application is vital in maintaining operational efficiency and safety in industrial settings.

Conclusion

In conclusion, spring washers are indispensable components in various manufacturing processes and applications. Their ability to provide consistent tension, resist loosening, and absorb shock makes them essential in ensuring the reliability of mechanical assemblies. As industries continue to evolve, the importance of spring washers in maintaining operational efficiency and safety cannot be overstated. Understanding their definition, manufacturing process, and applications equips engineers and manufacturers to make informed decisions about their use in various projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024