Supplier for Spring Washers and Flat Washers in Various Sizes and Materials

Understanding Spring Washers and Flat Washers A Comprehensive Guide for Suppliers

When it comes to mechanical components, washers play a critical role in ensuring the stability and functionality of various assemblies. Among the different types of washers, spring washers and flat washers are two of the most commonly used. Suppliers who specialize in these components must understand their distinct characteristics, applications, and the demands of the market to effectively cater to their customers.

What are Spring Washers?

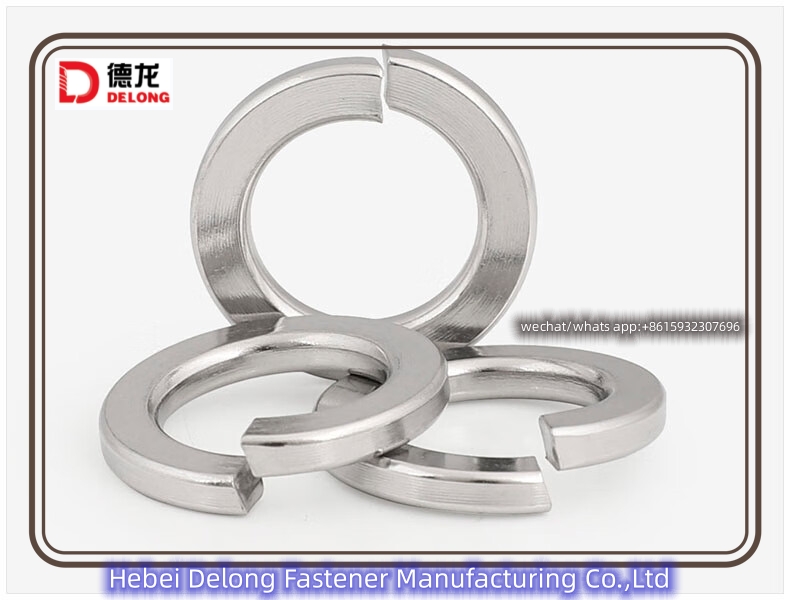

Spring washers are designed to provide a certain amount of elasticity and flexibility in a bolted joint or assembly. These washers are typically made from materials that can withstand stress and deformation, such as stainless steel, carbon steel, or spring steel. The primary purpose of spring washers is to absorb shock and vibrations, which can occur in dynamic environments. This feature makes them particularly beneficial in applications such as automotive engines, machinery, and high-speed equipment.

The most common type of spring washer is the split washer, or lock washer, which features a helical design. This design creates a spring effect that helps maintain clamping pressure, prevents loosening of fasteners over time, and minimizes the risk of failure in vibrating applications. Suppliers must ensure that these washers meet specific standards for quality and performance to guarantee their reliability in critical uses.

What are Flat Washers?

Flat washers, on the other hand, are simpler in design and serve a different purpose. Typically, they are thin, flat disks made from various materials, including plastic, metal, and rubber. The main function of flat washers is to distribute load, protect surfaces, reduce friction, and prevent loosening of nuts and bolts. They are commonly used in a wide range of applications, from general assembly work to precision machinery.

Flat washers come in various sizes and thicknesses, which allows them to accommodate different load requirements and fastener sizes. There are also specialized flat washers, such as fender washers and structural washers, which are designed for specific applications to improve performance and reliability. Suppliers need to maintain a diverse inventory of flat washers to meet the varied needs of their clients.

spring washer and flat washer order supplier

Market Demand and Supply Considerations

As industries continue to evolve, the demand for high-quality spring and flat washers has grown significantly. The global automotive industry, construction, and manufacturing sectors have driven this demand as they seek reliable components for their assemblies. Suppliers must stay updated on market trends, new materials, and manufacturing techniques to remain competitive.

Additionally, it is essential for suppliers to provide excellent customer service. This includes offering timely delivery, customization options, and technical support to help clients choose the right washers for their specific applications. Developing strong relationships with manufacturers and keeping abreast of industry standards will further enhance a supplier's reputation in the market.

Quality Assurance

Quality assurance is paramount when it comes to sourcing spring and flat washers. Suppliers should implement rigorous testing and inspection processes to ensure that the products meet industry standards and client specifications. Certifications such as ISO 9001 can provide assurance to customers about the quality management systems in place.

Moreover, suppliers should be aware of the importance of material selection. The choice of materials can significantly influence the performance characteristics of washers. For instance, stainless steel washers are preferred in corrosive environments, while carbon steel might be suitable for heavy-duty applications.

Conclusion

In conclusion, spring washers and flat washers are vital components in various mechanical assemblies. As a supplier, understanding the nuances, applications, and market demands of these washers is crucial for success. By focusing on quality, customer service, and the diverse needs of industries, suppliers can effectively position themselves in the competitive landscape while providing essential components that contribute to the reliability and performance of numerous applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024