split washer and flat washer exporters

Understanding the Export Market for Split Washers and Flat Washers

In the realm of industrial fasteners, split washers and flat washers play a crucial role in ensuring the integrity and longevity of various mechanical assemblies. These essential components serve unique purposes in fastening applications, making them widely sought after in multiple industries, including automotive, aerospace, construction, and machinery fabrication. As global demand for these products continues to rise, the role of exporters in the supply chain has become increasingly significant.

Split Washers Function and Application

Split washers, also known as helical spring washers, are designed to provide a locking function when used alongside bolts and nuts. Their unique design allows them to create a spring effect, absorbing vibrations and preventing loosening of fasteners due to movement or thermal expansion. This feature is especially important in high-stress applications, such as in automotive engines or machinery that experiences constant operational vibrations. Exporters specializing in split washers must ensure compliance with industry standards and provide quality products that meet specific mechanical specifications.

Flat Washers Versatility and Use Cases

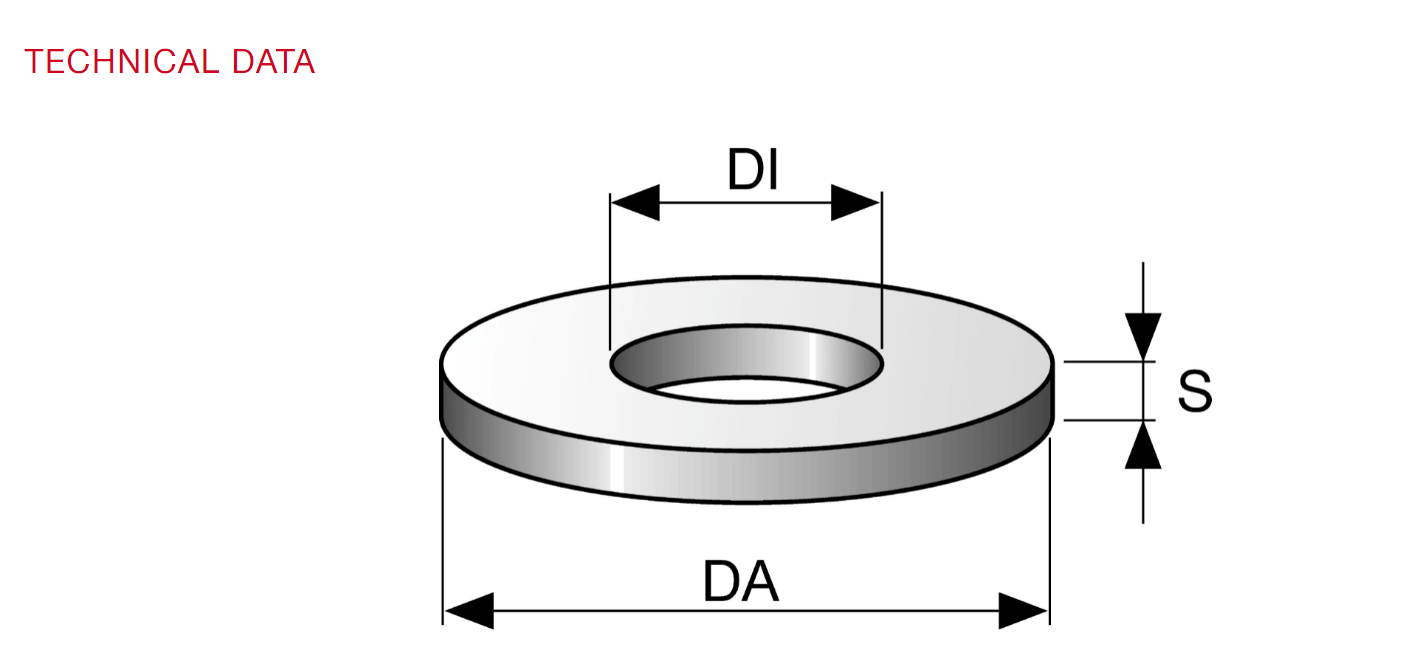

On the other hand, flat washers serve a different but equally important purpose. They are utilized to distribute the load of a fastener and prevent damage to the surface being fastened. Flat washers are available in various materials, including steel, stainless steel, plastic, and rubber, catering to diverse applications and environmental conditions. Their versatility makes them essential components in everything from household furniture assembly to industrial machinery. Exporters of flat washers must maintain a stock of different sizes and materials to meet the varied demands of their clients.

The Export Landscape

split washer and flat washer exporters

The export market for split and flat washers is influenced by several factors, including manufacturing capabilities, quality control, and international demand. Countries with robust manufacturing sectors, such as China, Germany, and the United States, have emerged as leading exporters of these fasteners. The trade dynamics are also shaped by trading agreements and tariffs, which can affect pricing and accessibility for countries importing these items.

Effective exporters often leverage digital platforms to reach a global audience, enabling them to showcase their products and capabilities to potential buyers. By participating in international trade fairs and exhibitions, they can establish connections and negotiate contracts with manufacturers and distributors worldwide.

Quality Assurance and Compliance

To thrive in the competitive export market, it is essential for exporters of split and flat washers to prioritize quality assurance. Adhering to international standards such as ISO certifications can significantly enhance their marketability. Buyers are increasingly scrutinizing the quality of fasteners, as subpar products can lead to costly failures and safety hazards.

Conclusion

The export market for split and flat washers is an intricate web of manufacturing, quality assurance, and international trade. As industries continue to evolve and grow, the demand for these essential components will remain strong. As such, exporters must stay attuned to industry trends, invest in quality practices, and seek innovative solutions to meet the ever-changing needs of their clients. With the right strategies in place, they can continue to thrive in this dynamic market.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024