Special Offers on 2014 Self-Drilling Wafer Head Screws for Your Next Project

The Evolution and Benefits of Discount Self-Drilling Wafer Head Screws in 2014

In the realm of construction and manufacturing, the importance of cost-effective and efficient fasteners cannot be overstated. Among the various types of screws available, self-drilling wafer head screws gained significant popularity, particularly in 2014, due to their unique features and advantages. This article explores the benefits of these screws, emphasizing their role in enhancing productivity while also offering considerable discounts.

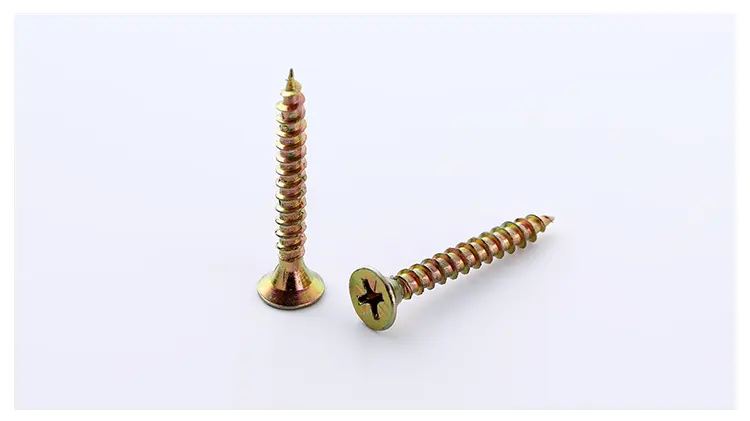

Self-drilling wafer head screws are designed with a distinctive head style that increases the surface area of the screw, providing a good grip and a sleek finish. This characteristic makes them ideal for applications where aesthetics matter, such as in sheet metal construction, facades, and architectural details. In 2014, many suppliers began to offer substantial discounts on these screws, making them more accessible for various projects, from large-scale industrial applications to small DIY tasks.

The Evolution and Benefits of Discount Self-Drilling Wafer Head Screws in 2014

Moreover, the self-drilling design of these screws allows for better penetration into various materials, including metal, wood, and plastic. This versatility means that they can be used in a wide range of applications. The structured design of the wafer head screw ensures a tight fit, reducing the risk of stripping and providing a secure hold. As a result, users can take advantage of the discounts on these fasteners without compromising on quality and durability.

discount 14 self drilling wafer head screw

In 2014, the construction and manufacturing industries were on an upswing, translating into higher demands for reliable and cost-effective materials. The introduction of significant discounts on self-drilling wafer head screws was timely, allowing businesses to optimize their spending while maintaining high standards of quality. Contractors were not just looking for the cheapest available options; they wanted products that could deliver performance and value. Self-drilling wafer head screws fit this bill perfectly.

Additionally, sustainability became a focal point in many industries by 2014, and the use of quality screws that reduced waste became a priority. Self-drilling screws minimize the risk of misdrilling and damage to materials, leading to lower waste levels and more sustainable practices. The discounts encouraged companies to invest in these sustainable options, knowing that they were not only making a responsible choice but also saving money in the process.

Lastly, the market for self-drilling wafer head screws in 2014 witnessed increased competition among manufacturers and distributors. This competition resulted in better pricing, improved product features, and more tailored solutions for customers. The introduction of discounts was not merely a marketing strategy; it demonstrated a genuine commitment from suppliers to meet customer needs, supporting businesses of all sizes.

In conclusion, the self-drilling wafer head screw was a standout product in 2014, largely due to the combination of its innovative design, practical applications, and significant discounts. As industries continue to evolve, the lessons learned from this period about efficiency, cost-effectiveness, and sustainability remain relevant, ensuring that these versatile fasteners will continue to play an integral role in construction and manufacturing for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024