serrated lock washer factory

Serrated Lock Washer Factory A Cornerstone of Industrial Fastening Solutions

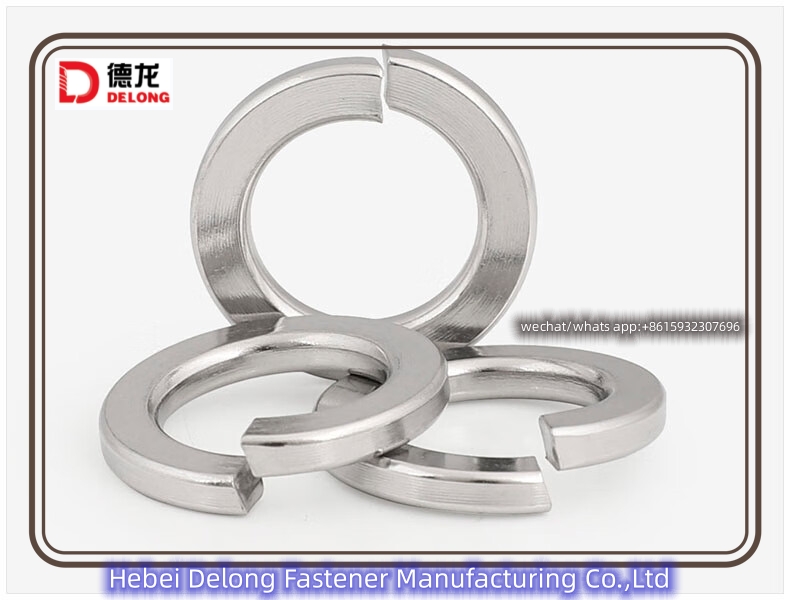

In the world of manufacturing and assembly, the importance of reliable fastening solutions cannot be overstated. Among these solutions, serrated lock washers play a vital role, ensuring the integrity and longevity of mechanical connections. The serrated lock washer factory stands as an essential cornerstone in this domain, producing these crucial components to meet the demands of various industries.

Serrated lock washers are designed to provide enhanced locking capability, preventing nut and bolt loosening under vibration and dynamic loads. Their unique serrated design enables them to grip the surfaces during tightening, creating friction and preventing movement. This feature makes them indispensable in automotive, aerospace, and heavy machinery applications where safety and reliability are paramount.

The manufacturing process of serrated lock washers involves precision engineering and quality control. Factories utilize advanced machinery and state-of-the-art techniques to produce washers that meet stringent industry standards. Metal strips are often used as raw material, which are cut, shaped, and treated to obtain the desired characteristics. Heat treatment may also be applied to enhance strength and durability, ensuring that these washers can withstand harsh environments and varying loads.

serrated lock washer factory

A key aspect of a serrated lock washer factory is its commitment to innovation. As industries evolve, so do their fastening needs. Factories continuously invest in research and development to create washers that cater to new materials and technologies. By partnering with engineers and designers, manufacturers can tailor their products to meet specific application requirements, promoting efficiency and safety in assembly processes.

Moreover, quality assurance is a critical component in the production of serrated lock washers. Factories implement rigorous testing protocols to ensure that each washer meets the required specifications. This includes tensile strength testing and dimensional inspections, which guarantee that the washers perform optimally under operational conditions. It is this dedication to quality that builds trust with clients and solidifies the reputation of manufacturers in the market.

In a global economy, serrated lock washer factories also play a significant role in supply chain dynamics. With the increasing demand for high-quality fastening solutions, these factories contribute to various industries worldwide, ensuring that manufacturing processes run smoothly and efficiently. Their ability to scale production and customize orders based on client needs underscores their value.

In conclusion, the serrated lock washer factory is a vital player in the industrial landscape, providing essential fastening solutions that enhance safety and efficiency. With a focus on innovation, quality, and responsiveness to market needs, these factories are poised to support the evolving requirements of industries for years to come. As the backbone of reliable assemblies, serrated lock washers continue to ensure that machinery operates effectively, contributing to advancements across numerous fields.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024