self tapping thumb screw factories

The Rise of Self-Tapping Thumb Screw Factories

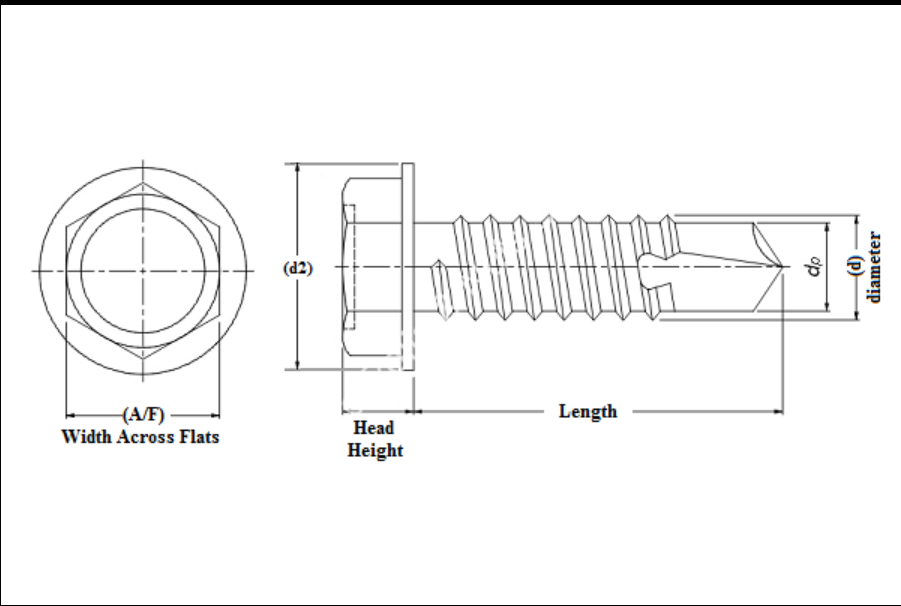

In the ever-evolving landscape of manufacturing, self-tapping thumb screws have emerged as essential components across various industries. These fasteners, designed to create their own threads in materials without needing a pre-drilled hole, are favored for their convenience and reliability. As the demand for these innovative screws continues to rise, so too does the proliferation of self-tapping thumb screw factories.

The Rise of Self-Tapping Thumb Screw Factories

The establishment of self-tapping thumb screw factories has been driven by advancements in manufacturing technologies. Automated production lines equipped with sophisticated machinery allow for high-precision fabrication, resulting in consistent quality and performance. These factories specialize in various types of thumb screws, catering to different specifications and requirements. By leveraging modern techniques, they can produce screws in bulk, ensuring that supply meets the growing demand.

self tapping thumb screw factories

Moreover, sustainability is becoming increasingly important in manufacturing practices. Many self-tapping thumb screw factories are adopting eco-friendly processes, utilizing recyclable materials and minimizing waste. This shift towards green manufacturing not only helps to preserve the environment but also appeals to consumers who are more conscious about sustainability. Factories that prioritize eco-friendly practices can enhance their brand reputation and attract a broader customer base.

In addition to traditional markets, the rise of e-commerce has opened new avenues for self-tapping thumb screw manufacturers. Online marketplaces provide a platform for factories to reach customers globally, allowing them to expand their reach beyond local borders. This accessibility means that even small manufacturers can compete on an international scale, providing high-quality products directly to consumers.

As technology continues to advance and markets evolve, the landscape of self-tapping thumb screw factories is likely to change. Innovations such as smart manufacturing and artificial intelligence could revolutionize production processes, making them even more efficient. Additionally, as industries continue to seek lighter and stronger materials, factories will need to adapt to meet these new demands.

In conclusion, the growth of self-tapping thumb screw factories is indicative of broader trends in manufacturing. With a focus on efficiency, sustainability, and global reach, these factories are well-positioned to meet the needs of diverse industries, driving innovation in fastener technology. The future looks bright for this segment of the manufacturing sector, as they continue to refine their processes and expand their market presence.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024